Preparation process of turbosuperchager nozzle ring blades for gasoline engines

A turbocharger and preparation technology, which is applied in the direction of turbines, mechanical equipment, metal processing equipment, etc., can solve the problems of low product quality stability, long production process, and increased production costs, so as to improve the one-time pass rate , Improve surface roughness, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

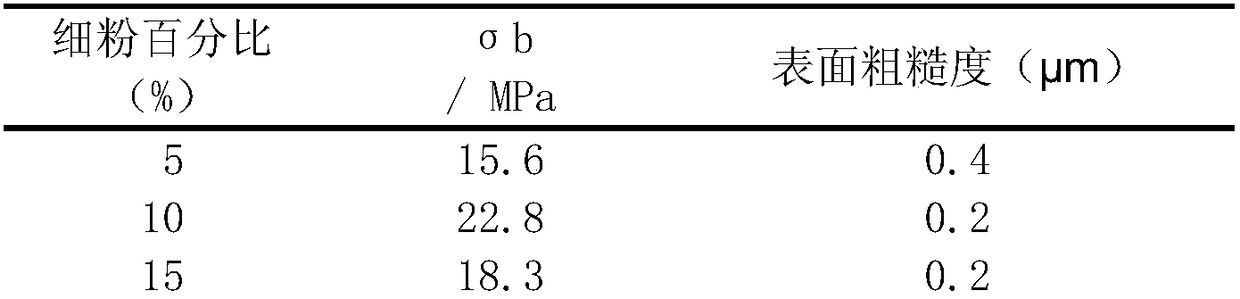

[0054] 1. Powder gradation: coarse powder 95%, micro powder 5%;

[0055] 2. Refining feed and injection molding blank

[0056] 2.1 The amount of binder added is 5%

[0057] 2.2 The banburying temperature is 150°C, the speed of the banbury mixer is 60r / min, and the banburying time is 1.5h;

[0058] 2.3 The injection temperature is 165°C, the injection pressure is 120Mpa, and the mold temperature is 50-60°C;

[0059] 3. Ultrasonic activation of skim base

[0060] 3.1 Degreasing process: heat to 160-180°C at a heating rate of 3°C-4°C / min, keep warm for 150-155 minutes, then heat to 320°C at a heating rate of 4-5°C / min, and keep warm for 160 minutes;

[0061] 3.2 Ultrasonic activation process: ultrasonic intensity is 0.4-0.5W / cm 2 , the ultrasonic time is 0.75h;

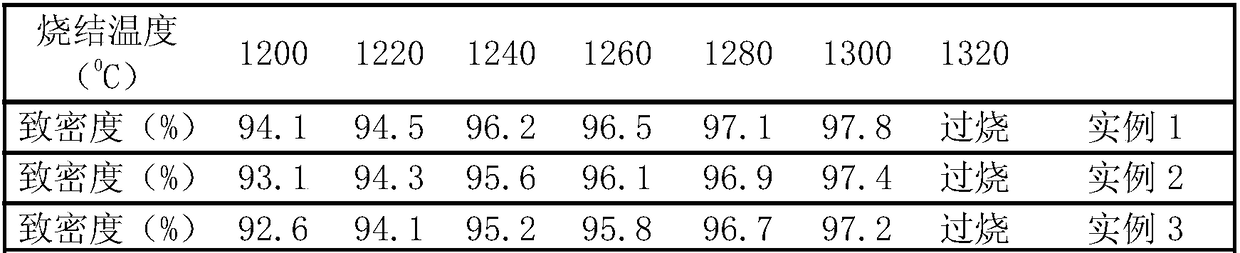

[0062] 4. Sintering process

[0063] The sintering temperature is 1200-1320°C, the heating rate is 5-7°C / min, and the holding time is 120 minutes.

Embodiment 2

[0065] 1. Powder gradation: coarse powder 90%, micro powder 10%;

[0066] 2. Refining feed and injection molding blank

[0067] 2.1 The amount of binder added is 10%

[0068] 2.2 The banburying temperature is 140°C, the speed of the banbury mixer is 40r / min, and the banburying time is 1h;

[0069] 2.3 The injection temperature is 140°C, the injection pressure is 80Mpa, and the mold temperature is 40-60°C;

[0070] 3. Ultrasonic activation of skim base

[0071] 3.1 Degreasing process: heat to 160-180°C at a heating rate of 3°C-4°C / min, hold for 160-170 minutes, then heat to 340°C at a heating rate of 4-5°C / min, and hold for 180 minutes;

[0072] 3.2 Ultrasonic activation process: ultrasonic intensity is 0.4-0.5W / cm 2 , the ultrasonic time is 0.75h;

[0073] 4. Sintering process

[0074] The sintering temperature is 1200-1320°C, the heating rate is 5-7°C / min, and the holding time is 120 minutes.

Embodiment 3

[0076] 1. Powder gradation: coarse powder 85%, micro powder 15%;

[0077] 2. Refining feed and injection molding blank

[0078] 2.1 The amount of binder added is 20%

[0079] 2.2 The banburying temperature is 120°C, the speed of the banbury mixer is 40r / min, and the banburying time is 1h;

[0080] 2.3 The injection temperature is 120°C, the injection pressure is 60Mpa, and the mold temperature is 30-50°C;

[0081] 3. Ultrasonic activation of skim base

[0082] 3.1 Degreasing process: heat up to 160-180°C at a heating rate of 3°C-4°C / min, hold for 170-180 minutes, then heat to 350°C at a heating rate of 4-5°C / min, and hold for 180 minutes;

[0083] 3.2 Ultrasonic activation process: ultrasonic intensity is 0.4-0.5W / cm 2 , the ultrasonic time is 1h;

[0084] 4. Sintering process

[0085] The sintering temperature is 1200-1320°C, the heating rate is 5-7°C / min, and the holding time is 120 minutes.

[0086] As can be seen from Table 2 and 3, the present invention has the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com