Cadmium telluride preparation method

A technology of cadmium telluride and cadmium telluride powder, which is applied in the direction of binary selenium/telluride compound, metal selenide/telluride, etc., can solve problems such as splashing, waste of cadmium telluride, and low product yield, and achieve equipment The effect of low requirements, high product yield and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention adopts following technical scheme: the preparation method of cadmium telluride, it comprises the following steps:

[0021] Step S1: homogeneously mix qualified tellurium powder, cadmium powder and cadmium telluride powder;

[0022] Step S2: Put the homogenized raw materials into the reaction container, then put the reaction container into the quartz tube in the atmosphere furnace, pass in the protective gas to discharge the air in the quartz tube, and then start to heat up at a rate of 5~20°C / min, heat up to 400~600°C, stop heating after holding for 0.5~3h;

[0023] Step S3: After the temperature is lower than 100°C, stop feeding the protective gas, and take out the furnace to obtain cadmium telluride;

[0024] In the step S1, the molar ratio of the tellurium powder and the cadmium powder is 1:1, and the mass of the cadmium telluride powder is 5-30% of the total weight of the tellurium powder and the cadmium powder.

[0025] The preparation meth...

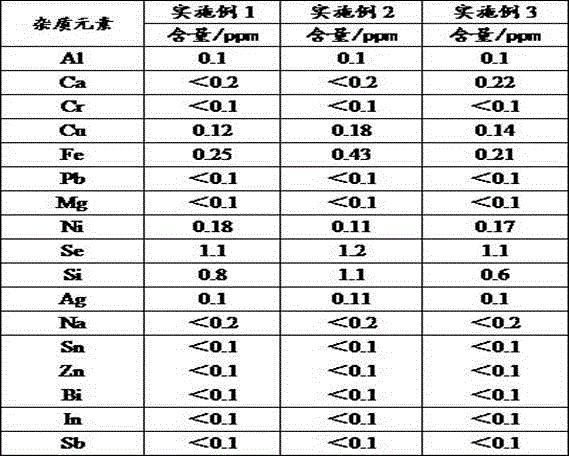

Embodiment 1

[0030] Step S1: Take 2.000kg of tellurium powder, 1.762kg of cadmium powder, and 1kg of cadmium telluride powder and mix them, and place them on a homogenizer for homogeneous mixing for 1 hour. 5N.

[0031] Step S2: Put the above-mentioned homogeneously mixed raw materials into the graphite boat, then put them into the quartz tube in the atmosphere furnace, cover the quartz tube with a quartz cap with a frosted mouth, seal the interface, and pass nitrogen gas into the quartz tube inlet pipe to discharge the quartz The air in the tube has a flow rate of 2L / min. After keeping the intake air for 30min, it starts to heat up at a rate of 10°C / min, and the temperature rises to 400°C. After holding for 3h, stop heating and continue to pass nitrogen.

[0032] Step S3: Start to lower the temperature naturally. When the temperature is lower than 100° C., stop the nitrogen flow, and get cadmium telluride out of the furnace.

[0033] Step S4: the cadmium telluride is crushed and sieved t...

Embodiment 2

[0036] Step S1: Take 5.000kg of tellurium powder, 4.404kg of cadmium powder, and 2.8kg of cadmium telluride powder and mix them, place them on a homogenizer for homogeneous mixing for 2.5 hours, the particle size of the tellurium powder, cadmium powder, and cadmium telluride powder are all less than 150 μm, The purity is 5N.

[0037] Step S2: Put the above-mentioned homogeneously mixed raw materials into the graphite boat, then put them into the quartz tube in the atmosphere furnace, cover the quartz tube with a quartz cap with a frosted mouth, seal the interface, and put hydrogen into the quartz tube inlet pipe to discharge the quartz The air in the tube has a flow rate of 4L / min. After keeping the intake air for 20min, it starts to heat up at a rate of 15°C / min, and the temperature rises to 500°C. After holding for 1h, stop heating and continue to flow hydrogen.

[0038] Step S3: Step S3: Start to lower the temperature naturally. When the temperature is lower than 100° C., s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com