Hydrofining method for Fischer-Tropsch oil

A technology of Fischer-Tropsch synthetic oil and Fischer-Tropsch synthesis, which is applied in the fields of petroleum wax refining, hydrotreating process, petroleum industry, etc., can solve problems such as complicated technological process, reduce coking and carbon deposition, and simplify technological process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 uses raw material a, and the volume ratio of catalyst A and catalyst B is 0.2:1.

[0028] Hydrogenation process conditions: reaction temperature 220°C, pressure 6MPa, liquid hourly volume space velocity for catalyst B 1.0h -1 , The volume ratio of hydrogen to oil is 600.

[0029] The properties of the obtained hydrogenated product are as follows: the distillation range <140°C, <380°C and <500°C are 4.2%, 49.9% and 78.0%, respectively, and the simulated distillation dry point is 698°C. <380°C distillate bromine value is 0.2gBr / 100g. After running for 100 hours, the carbon deposits of catalysts A and B were measured to be 3% (mass fraction) and 3.5% (mass fraction) respectively.

[0030] After separation of the obtained hydrogenated product, a fraction at 400-500°C is obtained, and its properties are as follows: melting point 58.5°C, oil content 0.9%, Saybolt color +29, light stability 3#, thermal stability 27#.

Embodiment 2

[0037] Embodiment 2 uses raw material b, and the volume ratio of catalyst A and catalyst B is 0.2:1.

[0038] Hydrogenation process conditions: reaction temperature 220°C, pressure 6MPa, liquid hourly volume space velocity for catalyst B 1.0h -1 , The volume ratio of hydrogen to oil is 600.

[0039] After running for 100 hours, the carbon deposits of catalysts A and B were measured to be 2.8% (mass fraction) and 3.0% (mass fraction) respectively.

[0040] The properties of the obtained hydrogenated product: the distillation range <140°C, <380°C and <500°C are 0.1%, 34.0% and 73.5% respectively, and the simulated distillation dry point is 673°C. <380°C distillate bromine value is 0.2gBr / 100g.

[0041] After separation of the obtained hydrogenated product, a 400-500°C fraction is obtained, and its properties are as follows: melting point 58.5°C, oil content 0.9%, Saybolt color +30, light stability 3#, thermal stability 28#.

Embodiment 3-6

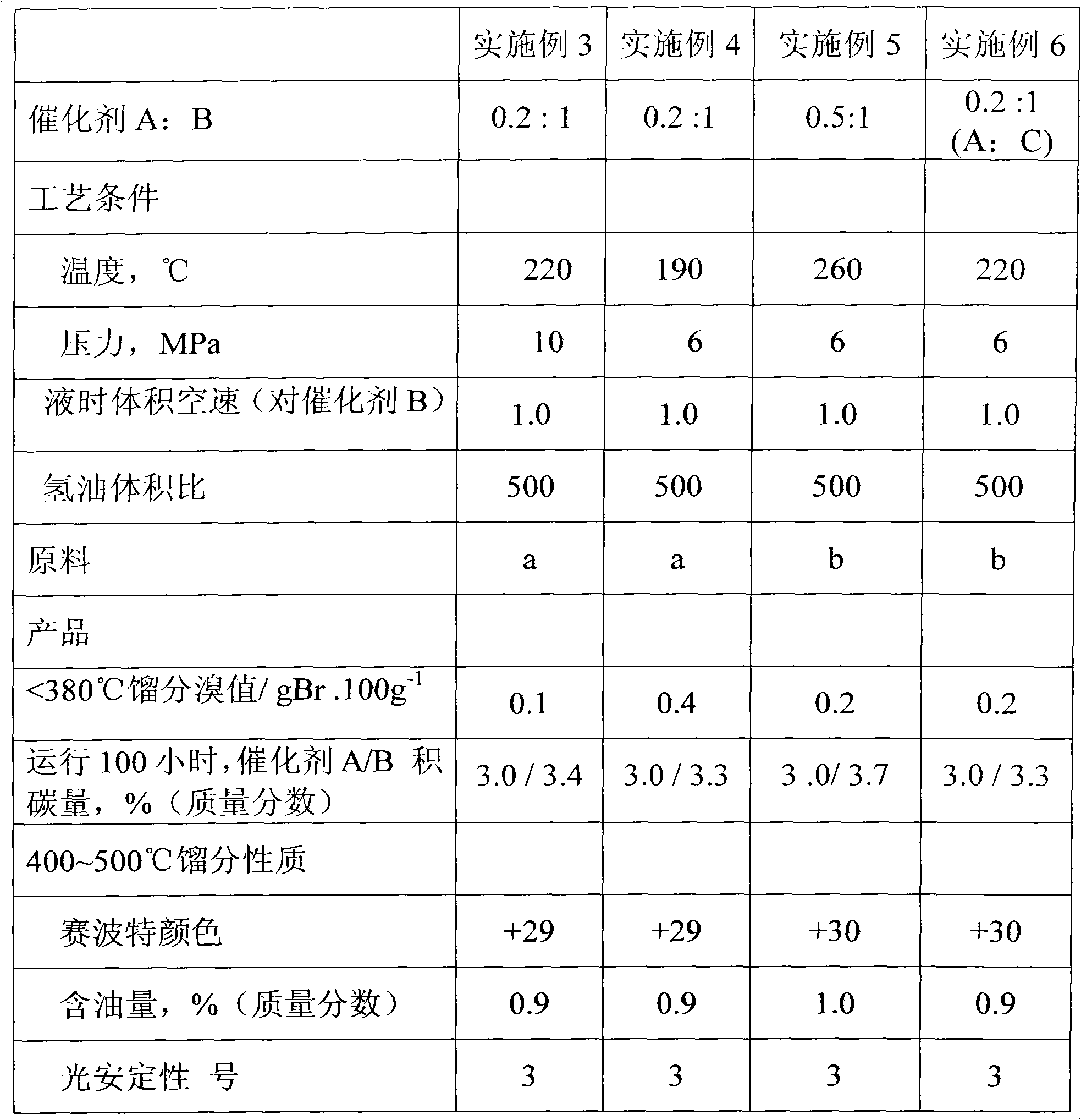

[0049] The raw materials, catalysts, reaction conditions and product properties used in Examples 3-6 are shown in Table 2, wherein Examples 3-5 use catalysts A and B, and Example 6 uses catalysts A and C.

[0050] Table 2

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com