Method for synthesizing phenolic resins by using paraformaldehyde

A technology of phenolic resin and paraformaldehyde, which is applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the problems of long reaction time, large amount of NaOH, and reduced resin performance. The production of process wastewater, the operation process is easy to control, and the effect of reducing the degree of severity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Turn on the stirring, and then pump 400kg of preheated phenol into the reactor under reduced pressure (the pressure is -0.06MPa), and then pump 100kg of recovered phenol-containing wastewater (with a pH value of 2 and a phenol content of 5.5%) ) into the reactor and remove the vacuum. Put 104kg of paraformaldehyde (with a content of 96%) into the reaction kettle under normal pressure, then heat up and heat evenly, and heat up to boiling in 30-40 minutes. Boiling reaction for 2 hours. Then lower the temperature to 70°C, add 2kg of oxalic acid solution, and heat up for 30 minutes to boil. Boiling reaction for 2 hours, dehydration under reduced pressure, when dehydration to 150°C, slowly increase the vacuum to 0.09MPa, and then discharge to obtain high-performance phenolic resin.

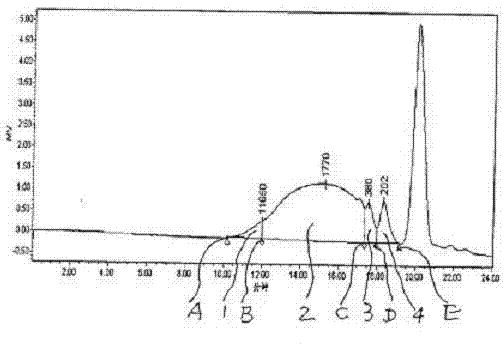

[0023] The parameters of the phenolic resin are as figure 1 shown, namely

[0024] serial number name Retention time (minutes) mn area %area 1 peak 2 12.000 1621...

Embodiment 2

[0032] Turn on the stirring, and then pump 400kg of preheated phenol into the reactor under reduced pressure (the pressure is -0.07MPa), and then pump 80kg of recovered phenol-containing wastewater (with a pH value of 1 and a phenol content of 6%) ) into the reactor and remove the vacuum. Put 108kg of paraformaldehyde (96% content) into the reaction kettle under normal pressure, then heat up, heat evenly, and heat up to boiling in 30-40 minutes. Boiling reaction for 2 hours. Then lower the temperature to 70°C, add 3kg of oxalic acid solution, and heat up for 30 minutes to boil. Boiling reaction for 3 hours, dehydration under reduced pressure, when dehydration to 150°C, slowly increase the vacuum to 0.09MPa, and then discharge to obtain high-performance phenolic resin.

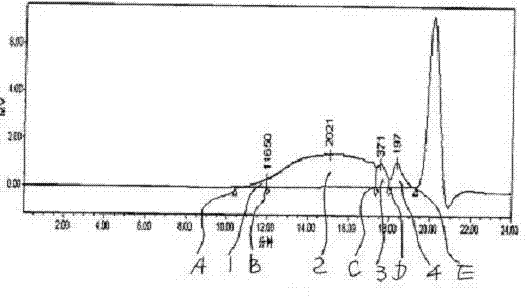

[0033] The performance parameters of the phenolic resin are as follows: figure 2 shown, namely

[0034] serial number name Retention time (minutes) mn area %area 1 peak 2 12.000 ...

Embodiment 3

[0042]Turn on the stirring, and then pump 400kg of preheated phenol into the reactor under reduced pressure (the pressure is -0.08MPa), and then pump 80kg of recovered phenol-containing wastewater (with a pH value of 1.5 and a phenol content of 5%) ) into the reactor and remove the vacuum. Put 106kg of paraformaldehyde (96% content) into the reaction kettle under normal pressure, then heat up, heat evenly, and heat up to boiling in 30-40 minutes. Boiling reaction for 2 hours. Then lower the temperature to 70°C, add 4kg of oxalic acid solution, and heat up for 30 minutes to boil. Boiling reaction for 4 hours, dehydration under reduced pressure, when dehydration to 150°C, slowly increase the vacuum to 0.09MPa, and then discharge to obtain high-performance phenolic resin.

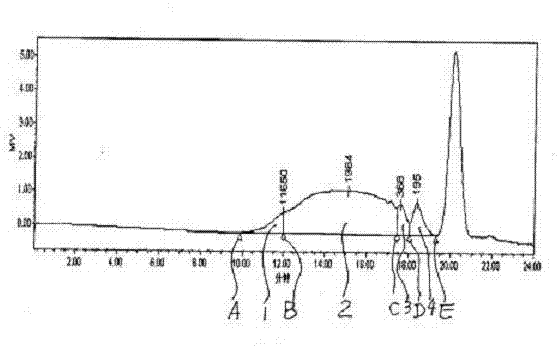

[0043] The performance parameters of the phenolic resin are as follows: image 3 shown, namely

[0044] serial number name Retention time (minutes) mn area %area 1 peak 2 12.000 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com