Wing type splitting energy absorption anchor rod and structure for preventing rockburst and large deformation

A large deformation, anti-rockburst technology, applied in the installation of bolts, mining equipment, earthwork drilling and other directions, can solve the problems of limited suction and pressure capacity, poor corrosion resistance and durability, unfavorable promotion and application, etc. Low cost and the effect of expanding the splitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

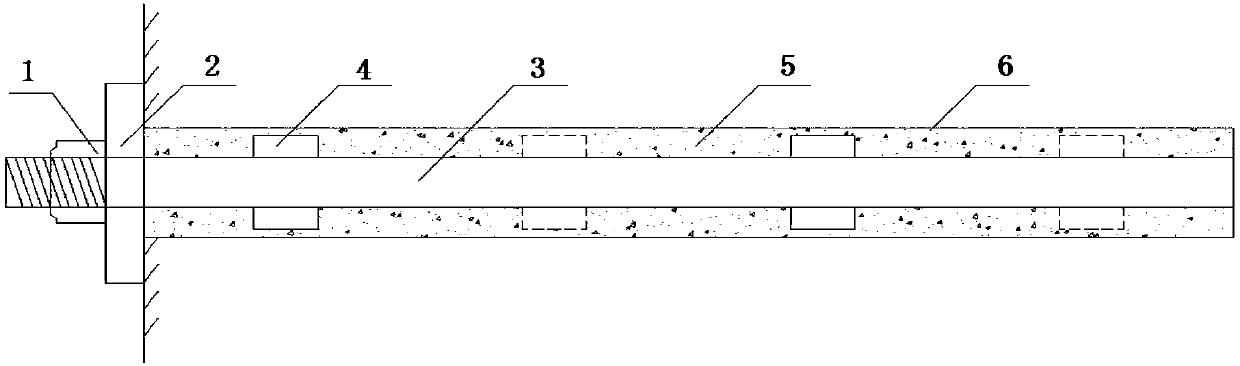

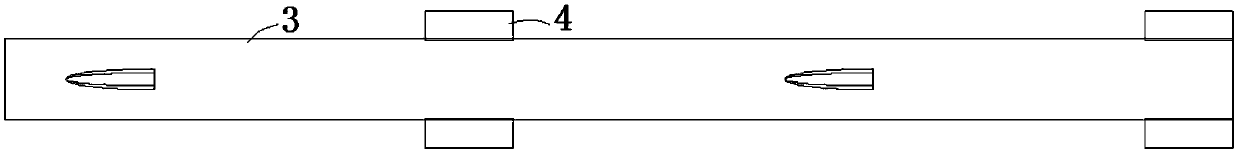

[0041] see figure 1 , an anti-rockburst and large-deformation wing-type splitting energy-absorbing bolt, comprising:

[0042] An anchor rod body 3 and a tray 2 and a nut 1 arranged at its tail;

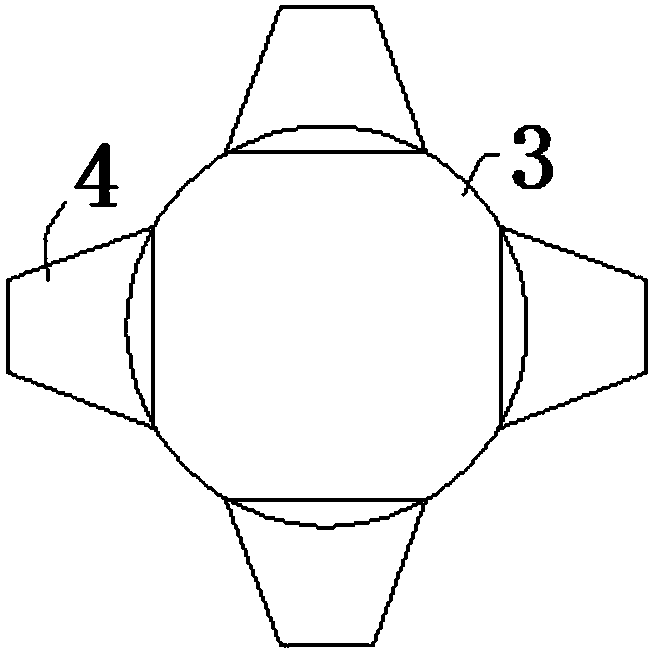

[0043] An anchoring wing 4 is arranged radially on the outer wall of the anchor rod body 3 . On the one hand, the anchor rod is positioned at the center of the borehole 6 to ensure the wrapping effect of the anchoring agent and the overall anchoring effect. At the same time, when subjected to rockburst or large deformation, the anchoring wing 4 splits the anchoring agent 5 and maintains a relatively stable resistance to slide in the borehole 6, producing coordinated deformation with the surrounding rock in space and time, absorbing and transferring the surrounding rock The released energy is suitable for disaster control such as rockburst or large deformation in deep underground engineering.

[0044] Generally, the outer wall of the anchor body 3 is a smooth surface. It is conveni...

Embodiment 2

[0060] see Image 6 and Figure 7 On the basis of the first embodiment, the cleavage arc surface 42 is set as an arc surface, relatively speaking, the impact surface is a little larger, which can increase the severity of the damage. Can be set as needed.

[0061] One or more technical solutions provided in the embodiments of this application have at least the following technical effects or advantages:

[0062] The anti-rockburst and large-deformation wing splitting type energy-absorbing bolt provided in the embodiment of the present application is provided with anchoring wings on the body of the bolt. The encapsulation effect and overall anchoring performance of anchoring agents such as resin or resin; at the same time, when subjected to rockburst or large deformation, the anchoring wing splits the anchoring agent and maintains a relatively stable resistance to slide in the borehole, in space and time. The surrounding rock produces coordinated deformation, absorbs and trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com