Preparation method of earthworm bioactive fulvic acid

A biologically active and fulvic acid technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low conversion rate, high cost, and large proportion of fulvic acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

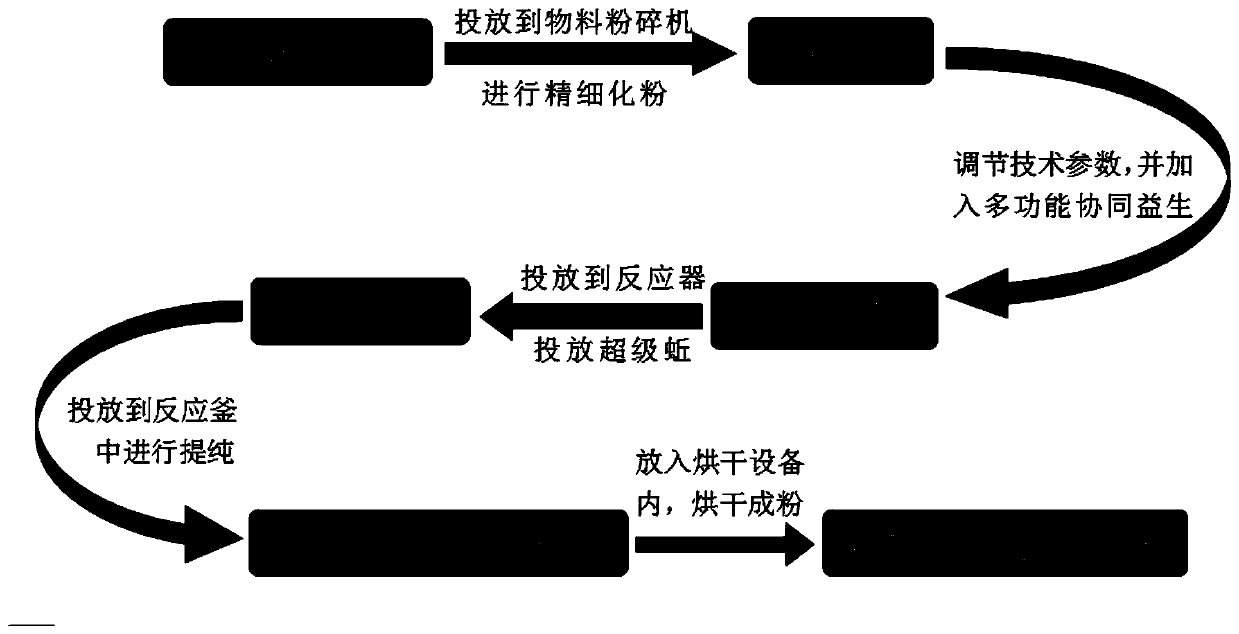

Method used

Image

Examples

specific Embodiment approach 1

[0034] Specific embodiment one: the preparation method of a kind of earthworm bioactive fulvic acid of the present embodiment, it is realized according to the following steps:

[0035] 1. The crop stalks are mixed with livestock and poultry manure, and fermented, and the fermented product is used as earthworm bait; wherein, in the fermented process, a compound microbial bacterial liquid mixed with 5 kinds of microbial strains is added at an inoculation amount of 0.1%; the microorganisms are Fusarium oxysporum, Neurospora sp., Phanerochaete chrysosporium, Bacillus subtilis and Bacillus acideler;

[0036] The initial conditions of fermentation treatment are carbon-nitrogen ratio of 25-30:1, humidity of 45-55%, pH value of 6.5-7.0, temperature of 8-20°C, and drum rotation every 24 hours during the fermentation process Turn over and ferment until the fineness of the product is ≦5mm;

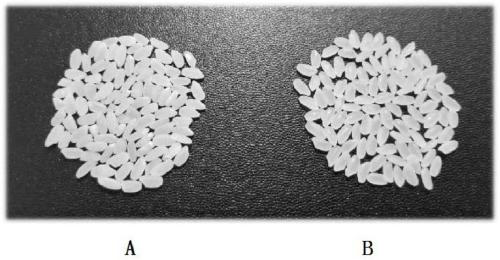

[0037] 2. Evenly put the earthworm bait obtained in step 1 into the bioreactor with earthworms f...

specific Embodiment approach 2

[0042] Specific embodiment 2: This embodiment differs from specific embodiment 1 in that: the livestock and poultry manure is a mixture of one or more of pig manure, sheep manure, and cow manure; crop straw is corn, rice, One or more mixed straws of soybeans and wheat. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the mass ratio of pig manure to corn straw is 1:4, the mass ratio of pig manure to rice straw is 1:3.5, and the mass ratio of pig manure to soybean straw The ratio is 1:5, and the mass ratio of pig manure to wheat straw is 1:6. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com