Inlet air heating system for a gas turbine engine

a gas turbine engine and heating system technology, applied in the direction of machines/engines, non-positive displacement fluid engines, gas turbine plants, etc., can solve the problems of increasing the temperature of the inlet air, reducing the power provided by reducing the power supply so as to reduce the power of the gas turbine engine without engine efficiency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

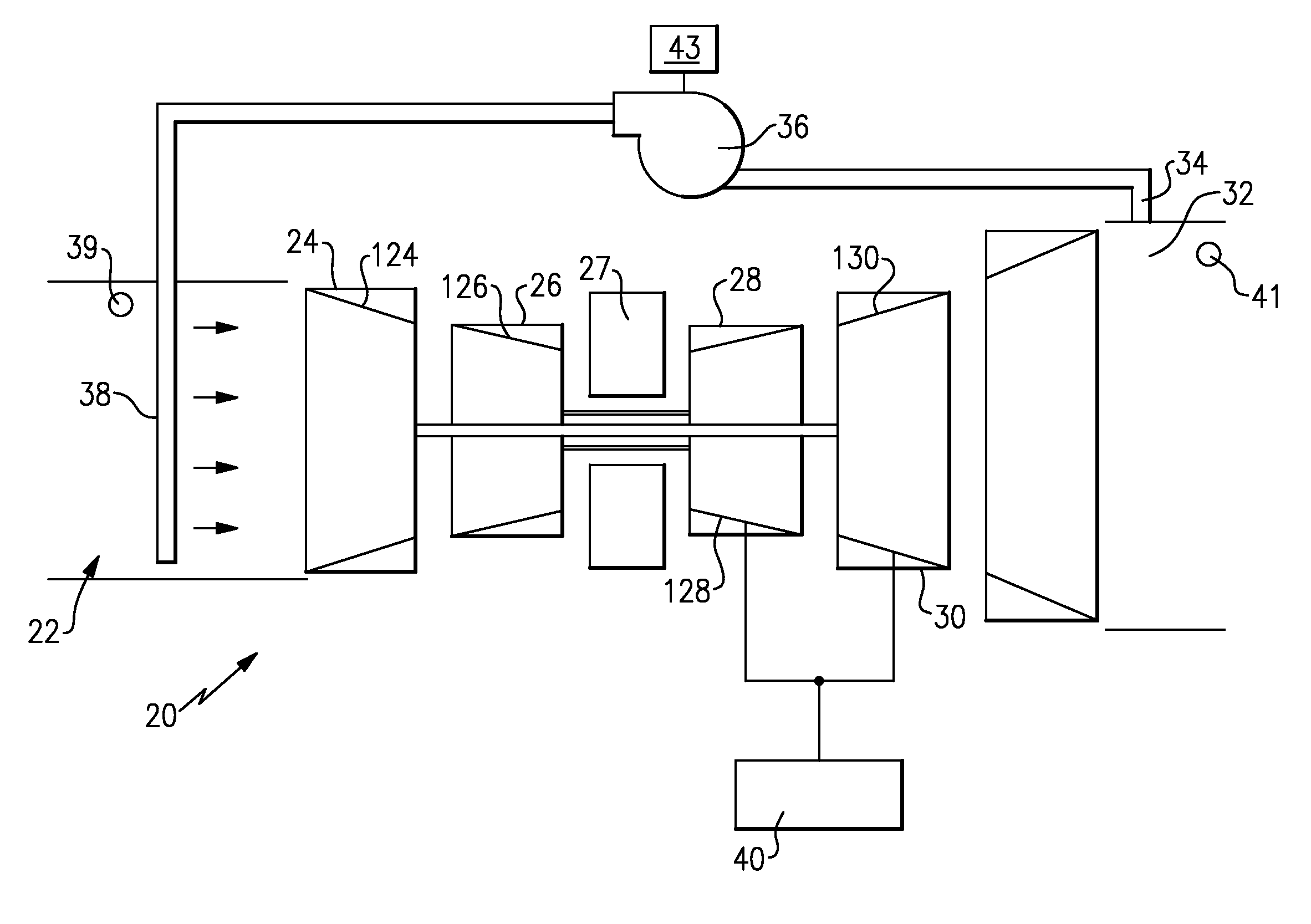

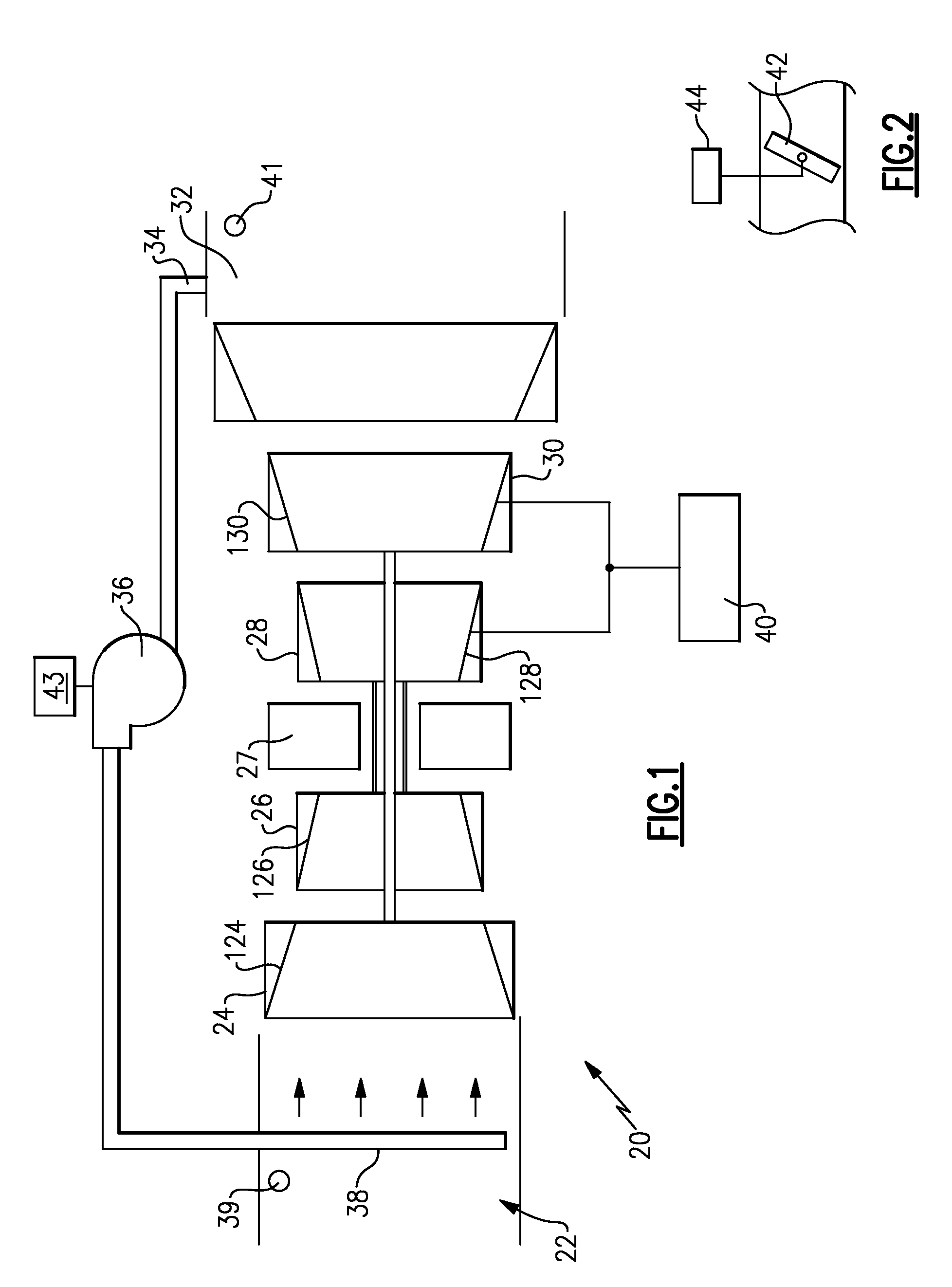

[0009]A gas turbine engine 20 is illustrated in FIG. 1. An inlet 22 delivers air to a low pressure compressor section 24, and downstream to a high pressure compressor section 26. Air from the compressor section 26 passes into a combustion section 27, and is mixed with fuel and burned. Preferably, the combustion section 27 is of a dry low NOx premix (DLN) type wherein fuel and air are premixed prior to combustion to assure flame temperatures are kept uniformly low to prevent formation of NOx. Products of this combustion pass over a high pressure turbine 28, and a low pressure turbine 30, driving the turbine rotors 128 and 130. The turbine rotors in turn drive compressor rotor 126 and compressor rotor 124, respectively. Downstream of the turbine sections the products of combustion pass into an exhaust 32. As shown, a tap line 34 taps a portion of the exhaust gas through a blower 36, and into a tap line 38. The tap line 38 bleeds gas into inlet 22 in controlled amounts. Although no fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com