Method for measuring single row conical bearing connection in series matched pair inter space

A single-row cone and measurement method technology, which is applied in mechanical clearance measurement, mechanical bearing testing, etc., can solve the problems of low work efficiency, many measurement times, and low measurement accuracy, and achieve the effects of simple operation, high measurement accuracy, and improved measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

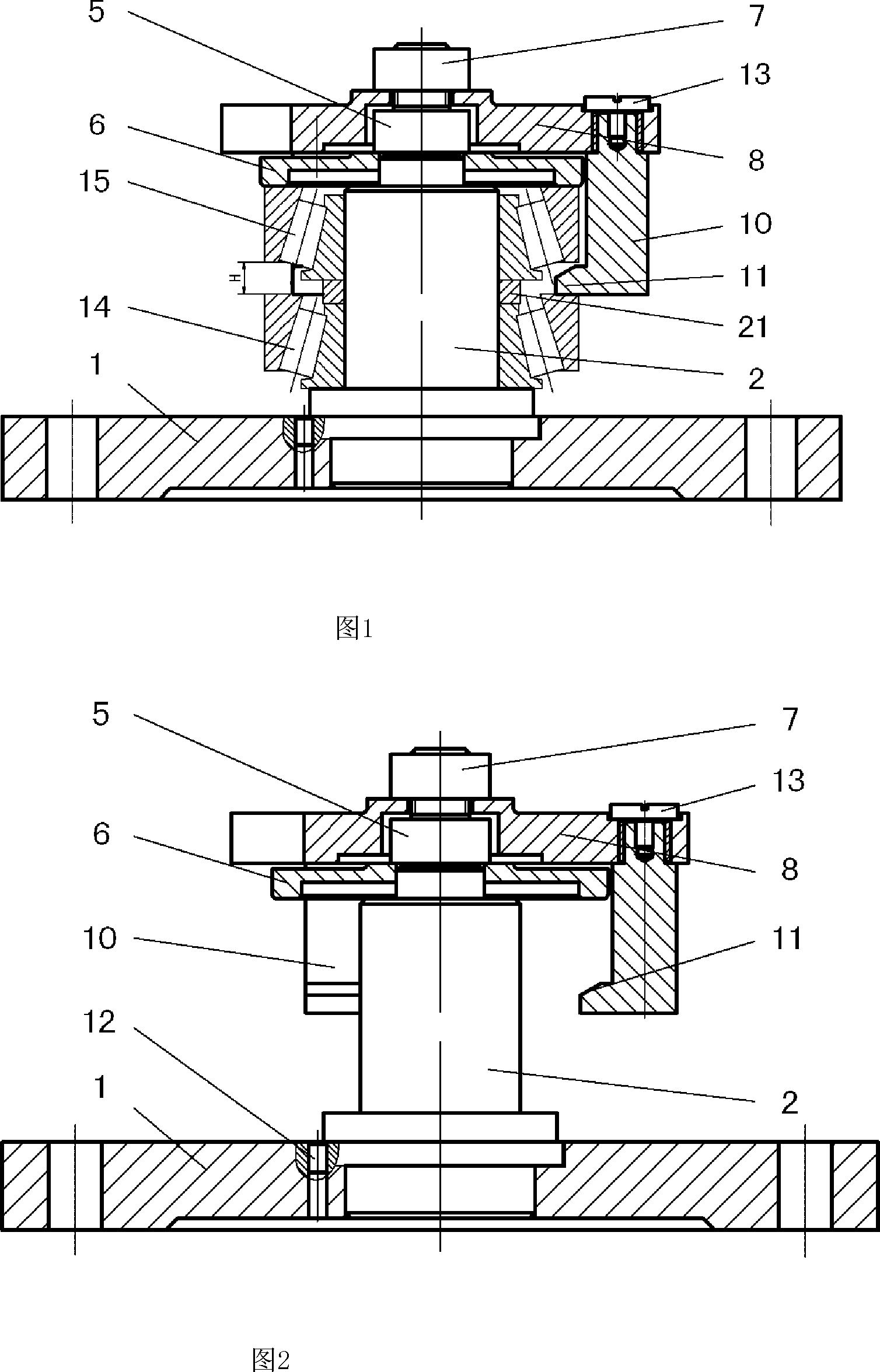

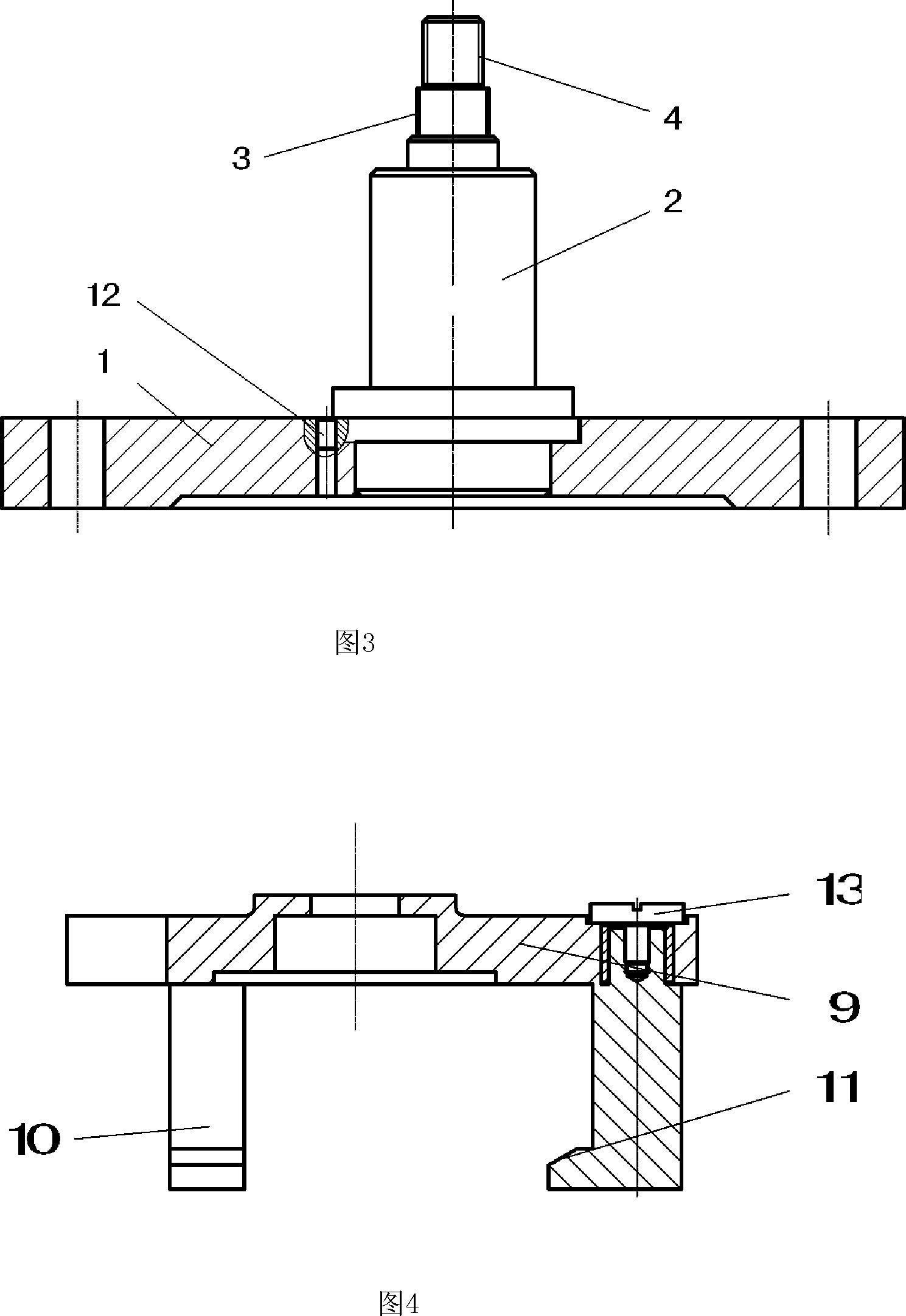

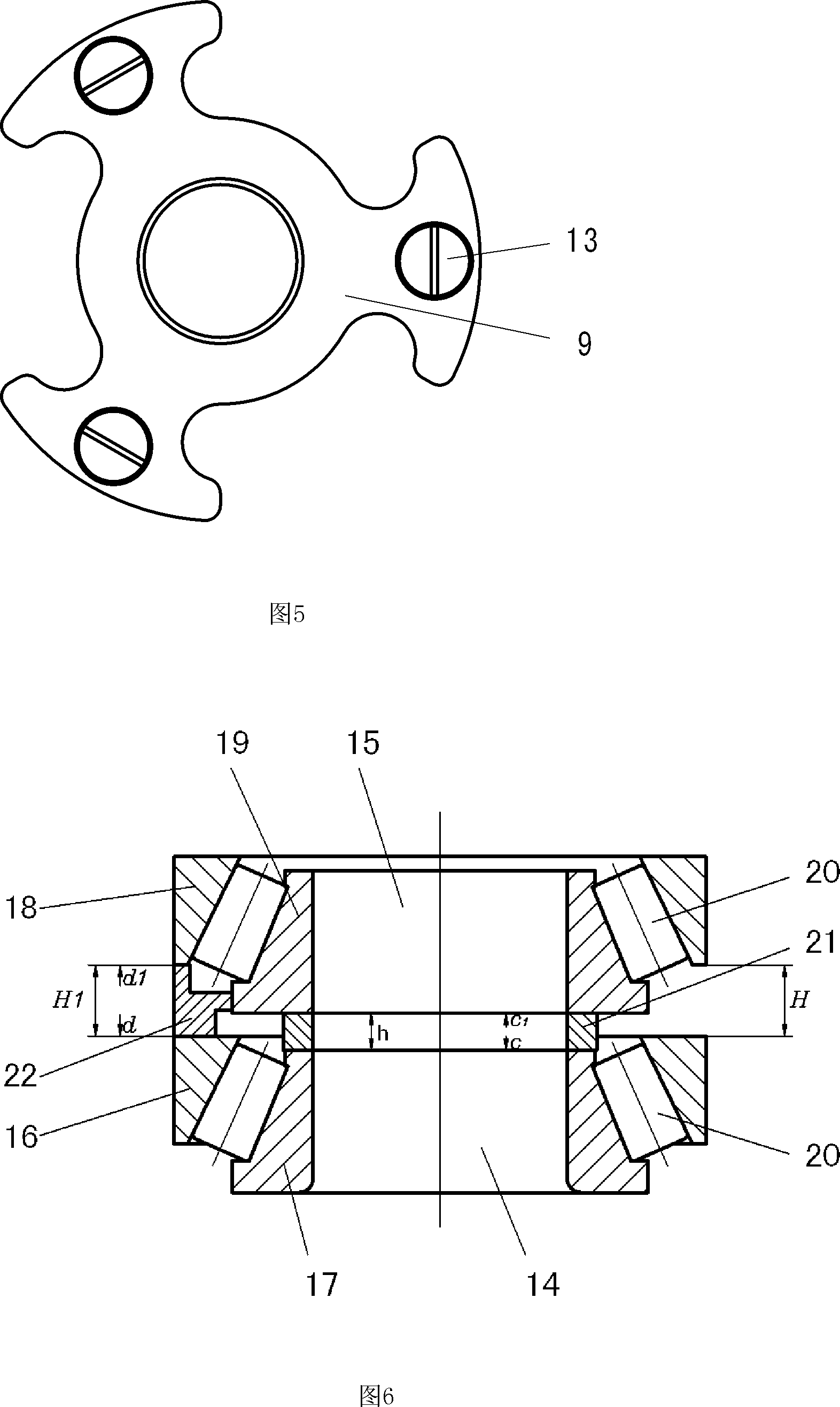

[0022] Embodiment: A method and device for measuring the gap between series pairs of single-row tapered bearings. The working object of the present invention is two paired bearings, called bearing first 14 and bearing second 15 respectively. A paired bearing set provided by a general bearing supplier includes a bearing A 14 and a bearing B 15 , and also includes an inner spacer 21 and an outer spacer 22 . The paired bearing set provided by the bearing supplier is shown in Figure 6 (in order to mark the distance H between the adjacent end faces of the outer rings of two series bearings in the figure, the outer spacer ring 22 on one side is not shown). In the figure, c represents the end face adjacent to the inner ring 17 of bearing A and the inner ring 19 of bearing B, d represents the end face adjacent to the outer ring 16 of bearing A and the outer ring 18 of bearing B, c 1 Indicates the end face adjacent to the inner ring 19 of bearing B and the inner ring 17 of bearing A, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com