Firearms

a barrel and assembly technology, applied in the field of barrel assembly, can solve the problems of high pressure within the barrel, possible barrel damage, and series of undesirable peripheral recesses in the bor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

In order that this invention may be more readily understood and put into practical effect, reference will now be made to the accompanying drawings which illustrate typical embodiments of the invention, wherein:

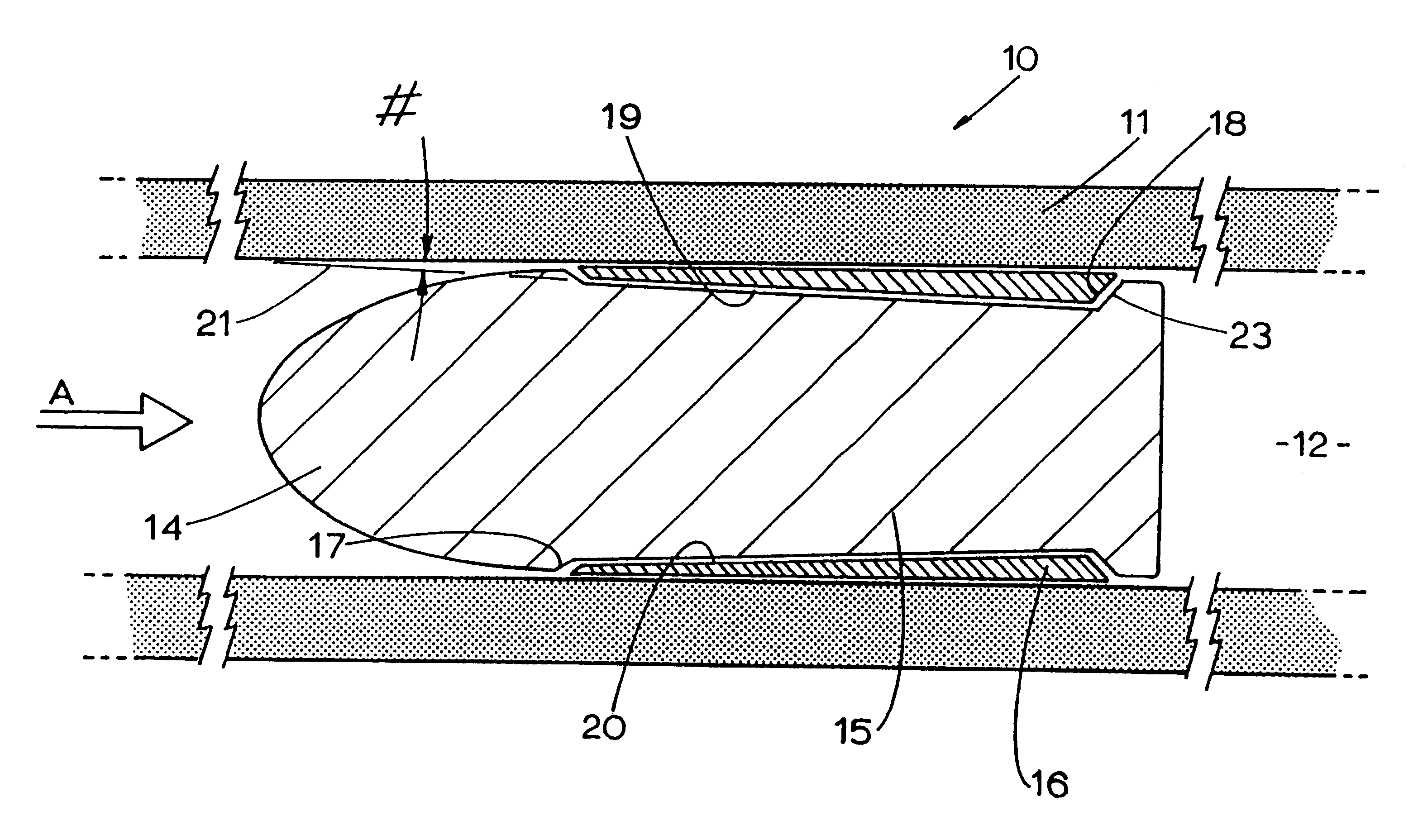

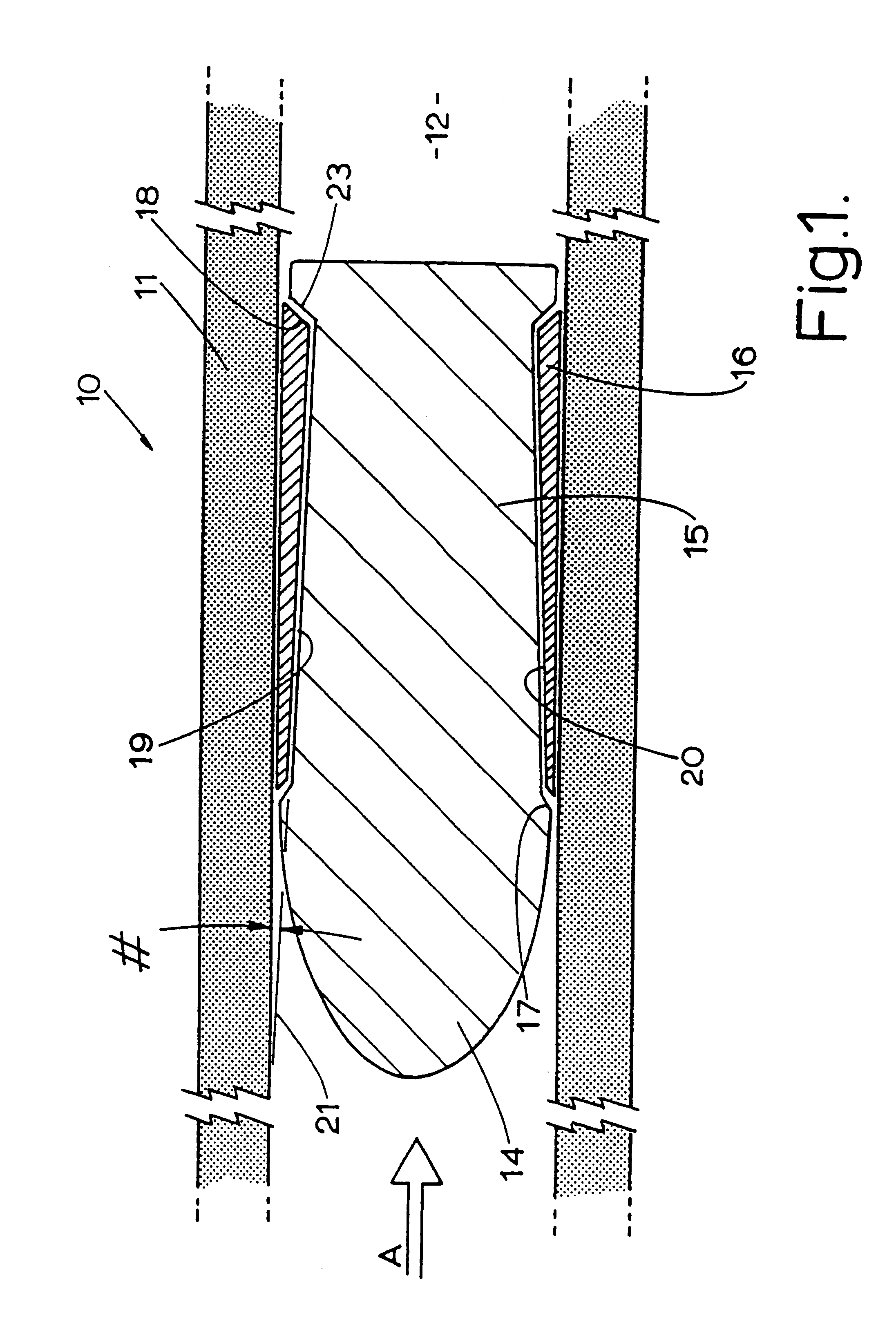

FIG. 1 is a diagrammatic cut-away view of a typical reverse wedging projectile according to one aspect of this invention;

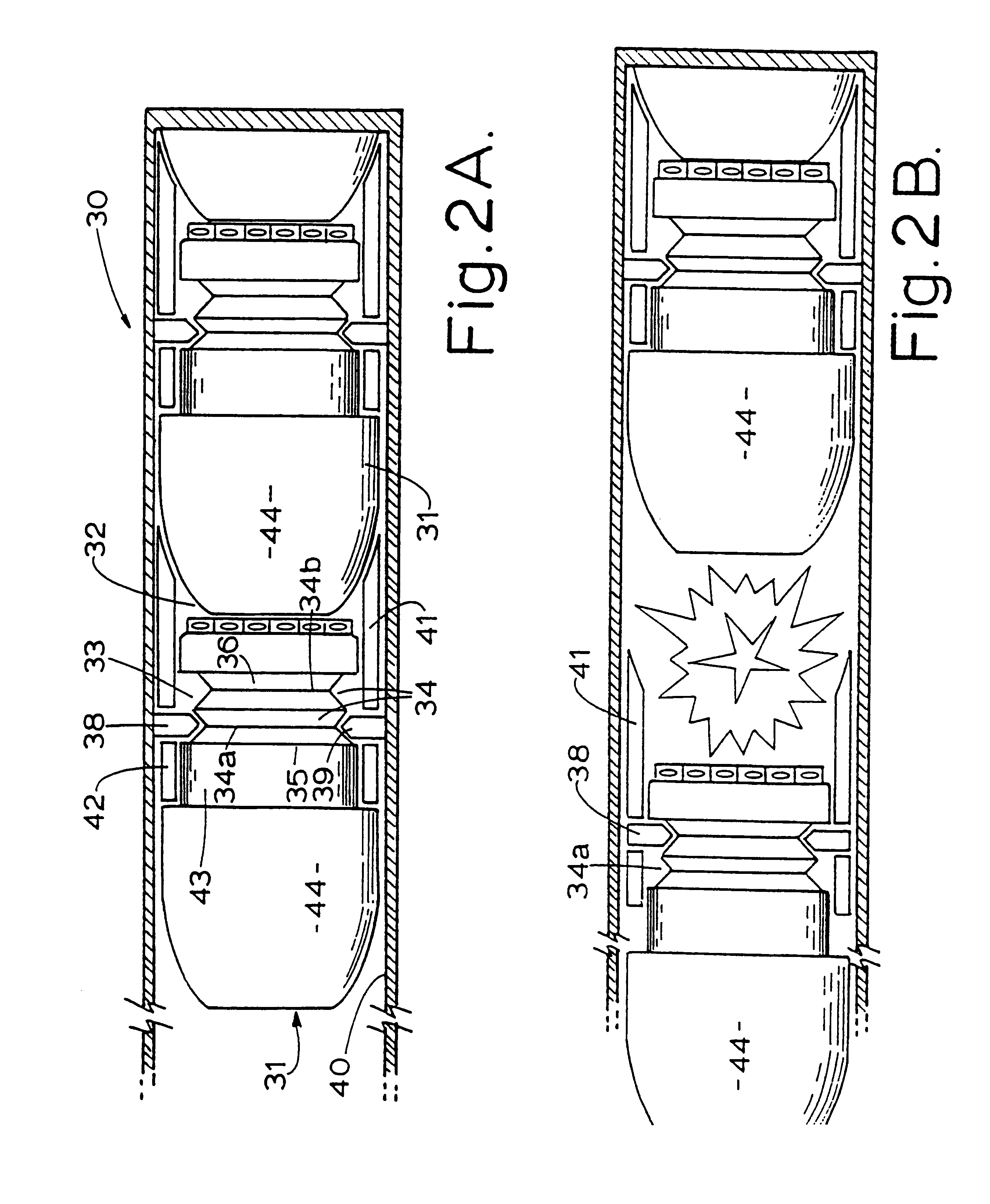

FIGS. 2A and 2B diagrammatically illustrate operation of a further reverse wedging projectile according to another aspect of this invention, and

FIG. 3 diagrammatically illustrates a further reverse wedging projectile according to yet another aspect of this invention.

According to the embodiment illustrated in FIG. 1, each projectile assembly 10 in a barrel of the type described is supported in a barrel 11 together with propellant in the trailing space 12 immediately behind the projectile assembly 10.

Each projectile assembly 10 includes a generally bullet shaped body part 14 having a part-conical rearwardly reducing trailing portion 15 which has an outer surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com