Heat Sink Rail System

a rail system and heat sink technology, applied in the direction of weapons, butts, weapon components, etc., can solve the problems of shortening the effective life of the barrel, affecting so as to reduce the impact of the shooter's grip on the accuracy of the firearm, the effect of dispersing heat within the rail system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

FIGS. 1, 7

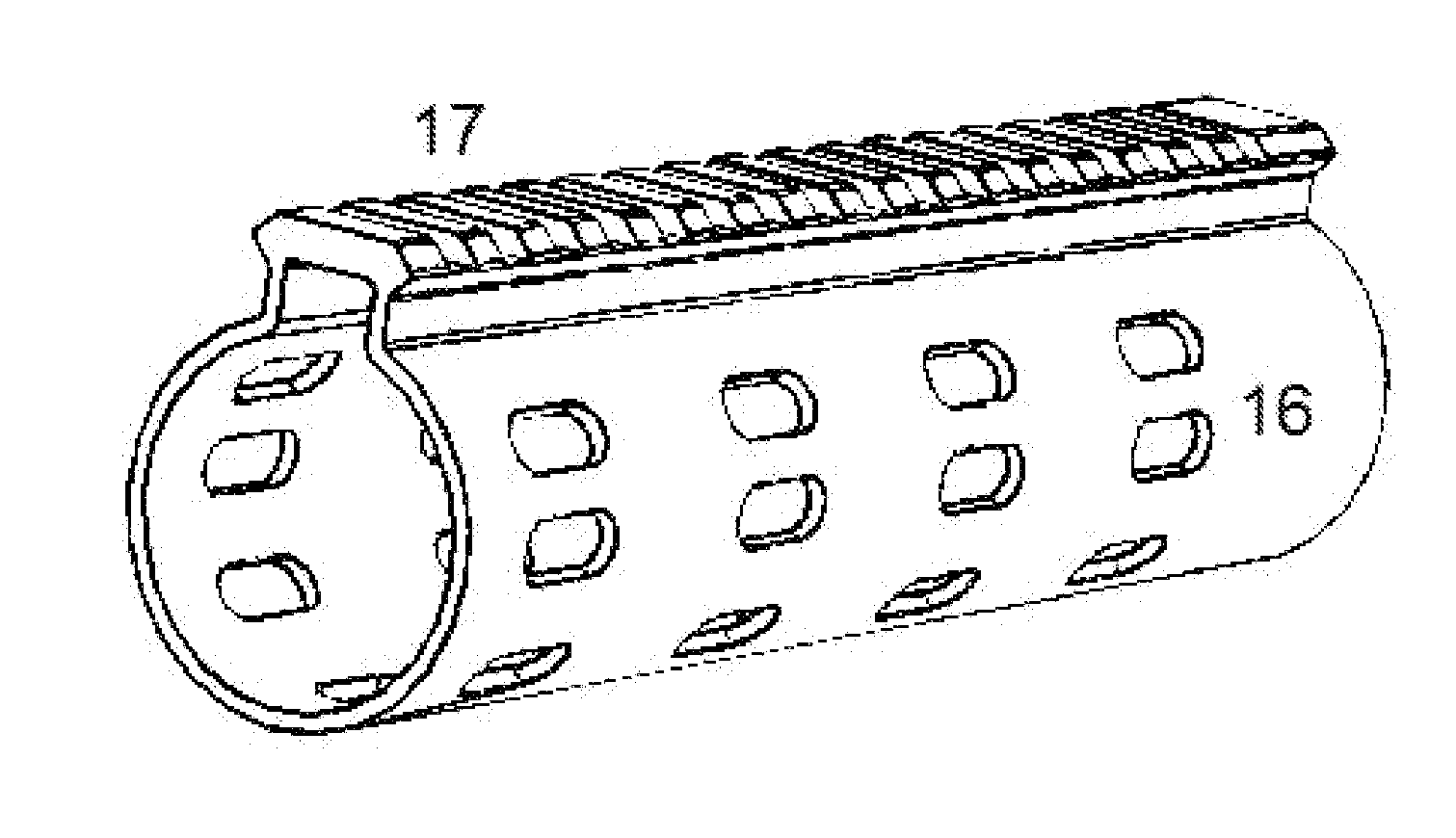

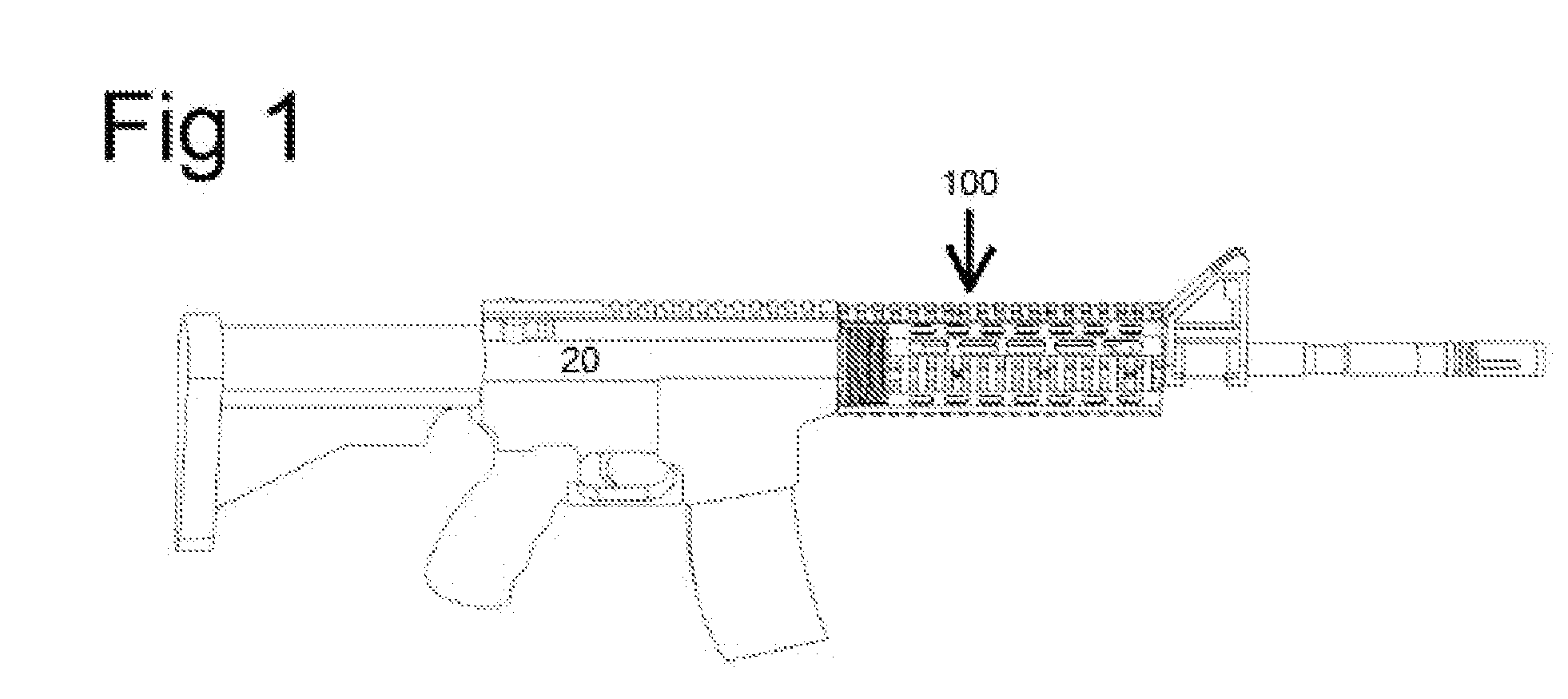

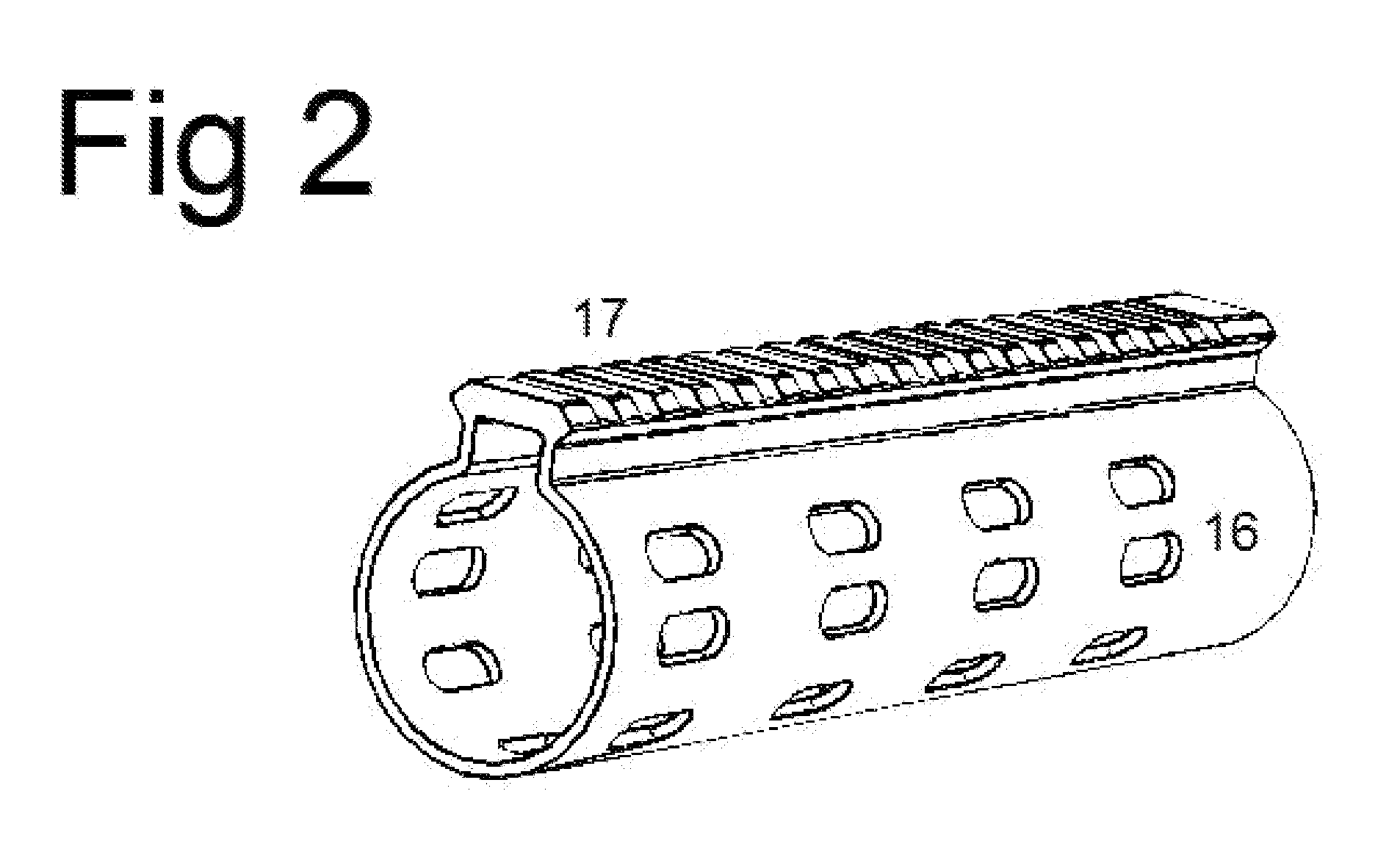

[0026]With reference now to the drawings, the preferred embodiment of the heat sink rail system according the present invention is herein described. As can be seen in FIG. 1, according to certain embodiments of the prior art, the rail system 100 is situated around barrel 11 of the firearm 20. Rail system 10 contains holes for air to pass through. Rail system 100 allows shooter to grip firearm at a distance from barrel 11 such that heat from barrel 11 does not fully reach shooter's grip.

[0027]As can be seen in FIG. 7, according to certain embodiments of the present invention, rail system 10 is situated around barrel 11 of firearm 20. Fins 12 extend inwards from inner layer of cooling system 13. Inner layer of cooling system 13 is circumscribed by o-rings 14, made, in certain embodiments of the present invention, of non-conducting material, which are circumscribed by outer layer of cooling system 15. Outer layer of cooling system 15 is circumscribed by rail cover 16. Railing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com