Water leakage heat absorption type pipeline leak detecting method

An endothermic and pipeline technology, which is applied in the field of leaking water leaking endothermic pipeline leak detection method, can solve the problems of uncertainty, serious water leakage loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

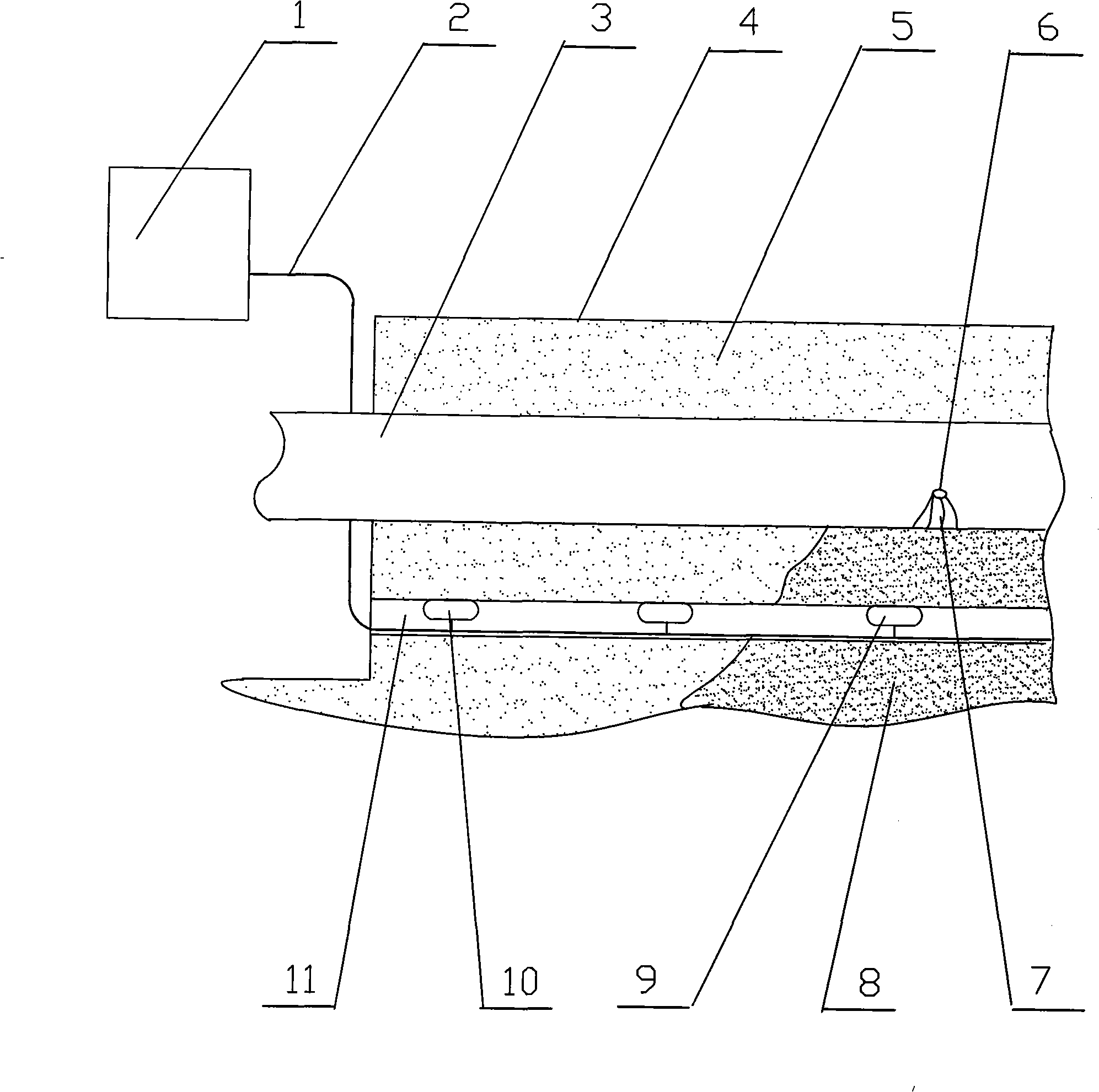

[0008] figure 1 1 is the ground controller, 2 is the wiring harness, 3 is the water pipe, 4 is the ground, 5 is the soil, 6 is the water leakage hole, 7 is the water leakage, 8 is the soil layer under the pipe affected by the water leakage, and 9 is the water leakage (The so-called detection probe is a thermally conductive sealing body that combines the heat source body, temperature sensor, code detector and AND gate circuit), 10 is a detection probe that is not at the water leakage level, and 11 is a thermally conductive protection tube. The water pipe 3 is buried in the soil 5 under the ground 4, and the protective pipe 11 with thermal conductivity is arranged below the water pipe 3. The upper part of the wiring harness 2 is connected to the ground controller 1, and the lower part is connected to the wire and connected to several detection probes (detection probes). There are many in actual use, only the initial three are drawn in the figure), the wire bundle 2 and all the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com