Heat-reflection fabric and application thereof to clothes

A technology of heat reflection and fabric, applied in the direction of one-component polyolefin rayon, one-component polyamide rayon, one-component polyester rayon, etc. The fabric is breathable, moisture-permeable and comfortable, so as to reduce the effect of heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0020] Fabric: pongee;

[0021] Yarn: 50D / 36F heat reflective polyester yarn

[0022] The content of each component in the heat-reflecting particles in the yarn is as follows: 80% of nano-titanium dioxide, 0% of aluminum oxide, 0% of zinc oxide, and 20% of indium tin oxide.

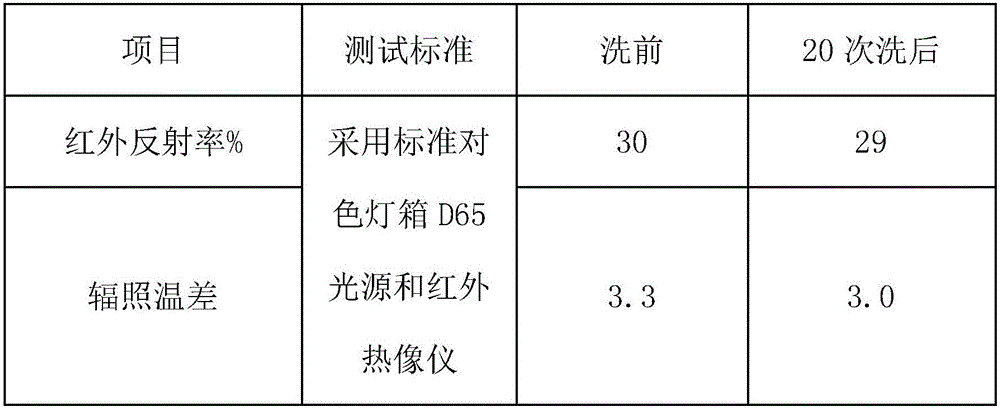

[0023] Table 1 Functional test results

[0024]

Embodiment example 2

[0026] Fabric: heat reflective 40D nylon double line grid;

[0027] Yarn: 40D / 36F heat reflective nylon yarn

[0028] The content of each component in the heat-reflecting particles of the yarn is as follows: 60% of nano titanium dioxide, 10% of aluminum oxide, 15% of zinc oxide and 15% of indium tin oxide.

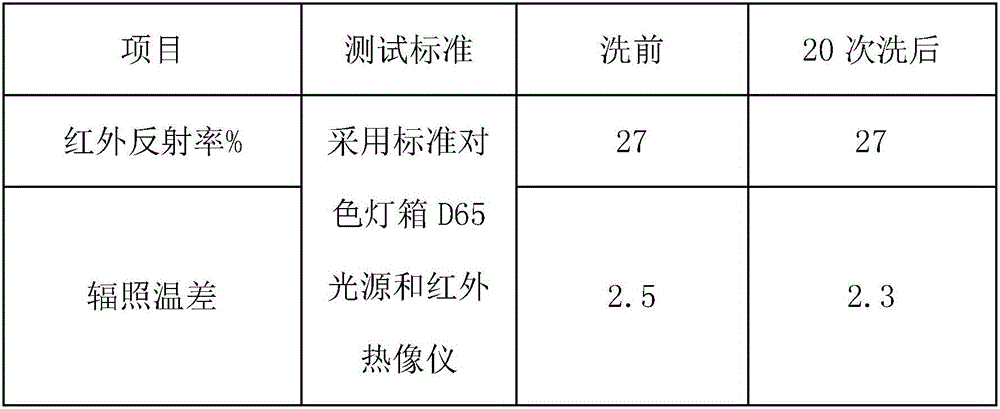

[0029] Table 2 Functional test results

[0030]

Embodiment example 3

[0032] Fabric: heat reflective jersey;

[0033] Yarn: 50D / 36F heat reflective polyester yarn;

[0034] The content of each component in the heat-reflecting particles of the yarn is as follows: 40% of nano-titanium dioxide, 20% of aluminum oxide, 20% of zinc oxide, and 20% of indium tin oxide.

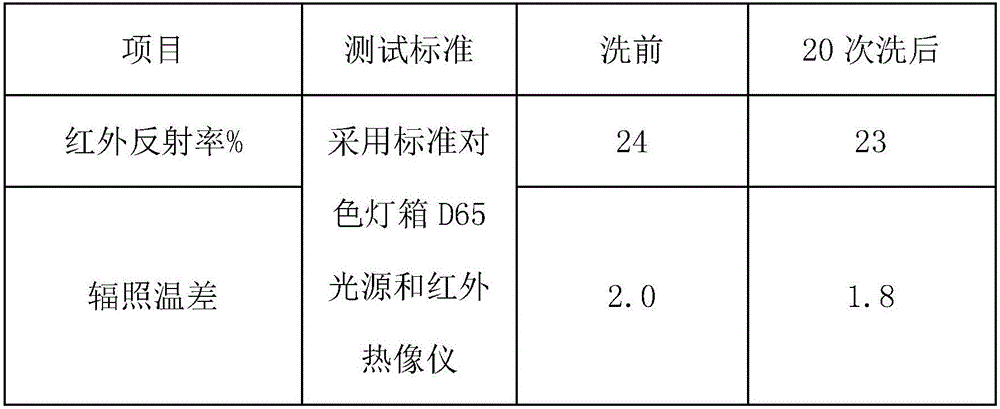

[0035] Table 3 Functional test results

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com