Experiment-type metallic solution cavitation corrosion apparatus

A metal solution and cavitation corrosion technology, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as unclear corrosion mechanism and corrosion, so as to simplify and cumbersome, improve experimental efficiency, and save experimental cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

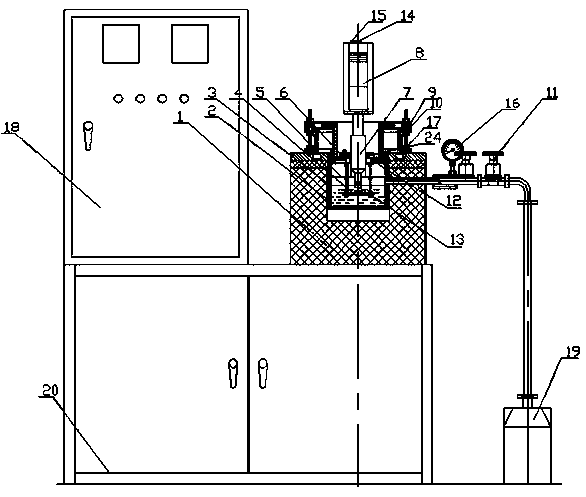

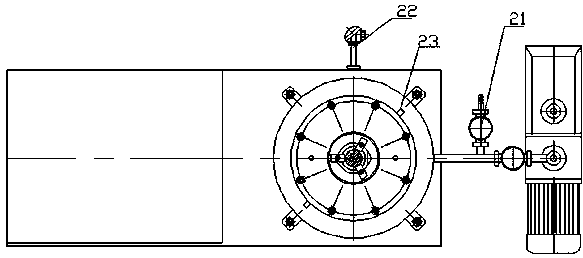

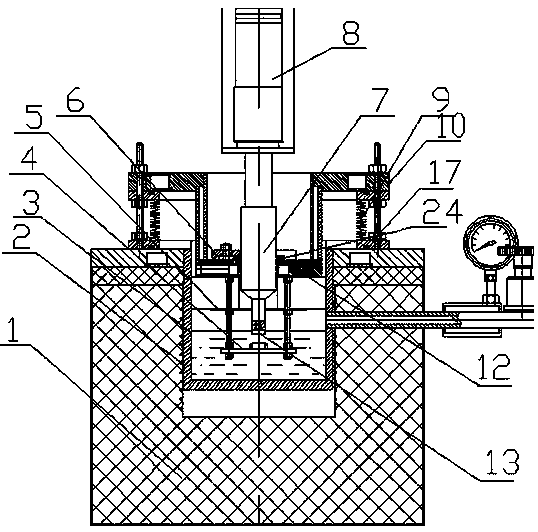

[0038] In the accompanying drawings, the device is mainly composed of a furnace body insulation layer 1, a resistance heating wire 2, a crucible 3, an ultrasonic horn 7, a transducer 8, a welded bellows 9, a large flange 10, a resistance furnace control cabinet 18, a rotary The chip-type direct-connected vacuum pump 19 and other components scientifically and rationally simulate the cavitation corrosion caused by high-speed liquid metal to nuclear reaction equipment.

[0039] Below in conjunction with accompanying drawing, the present invention is further elaborated and illustrated:

[0040] Concrete implementation steps are as follows:

[0041] Check whether each device, control box, sealing mechanism, etc. are in good condition; put the sample on the sample table 4, control the distance between the sample table and the sample 13 at the end of the horn by adjusting the nut on the connecting rod, and lock the position After the ultrasonic horn 7 is tightly connected with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com