Novel high-efficiency energy-saving environmentally-friendly combustor

A high-efficiency energy-saving burner technology, which is applied in the direction of heating fuel, household appliance efficiency improvement, gaseous heating fuel, etc., can solve the problems of burner thermal efficiency reduction, yellow flame, thermal efficiency reduction, etc., and achieve combustion efficiency and exchange efficiency. Speed up the heating process and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

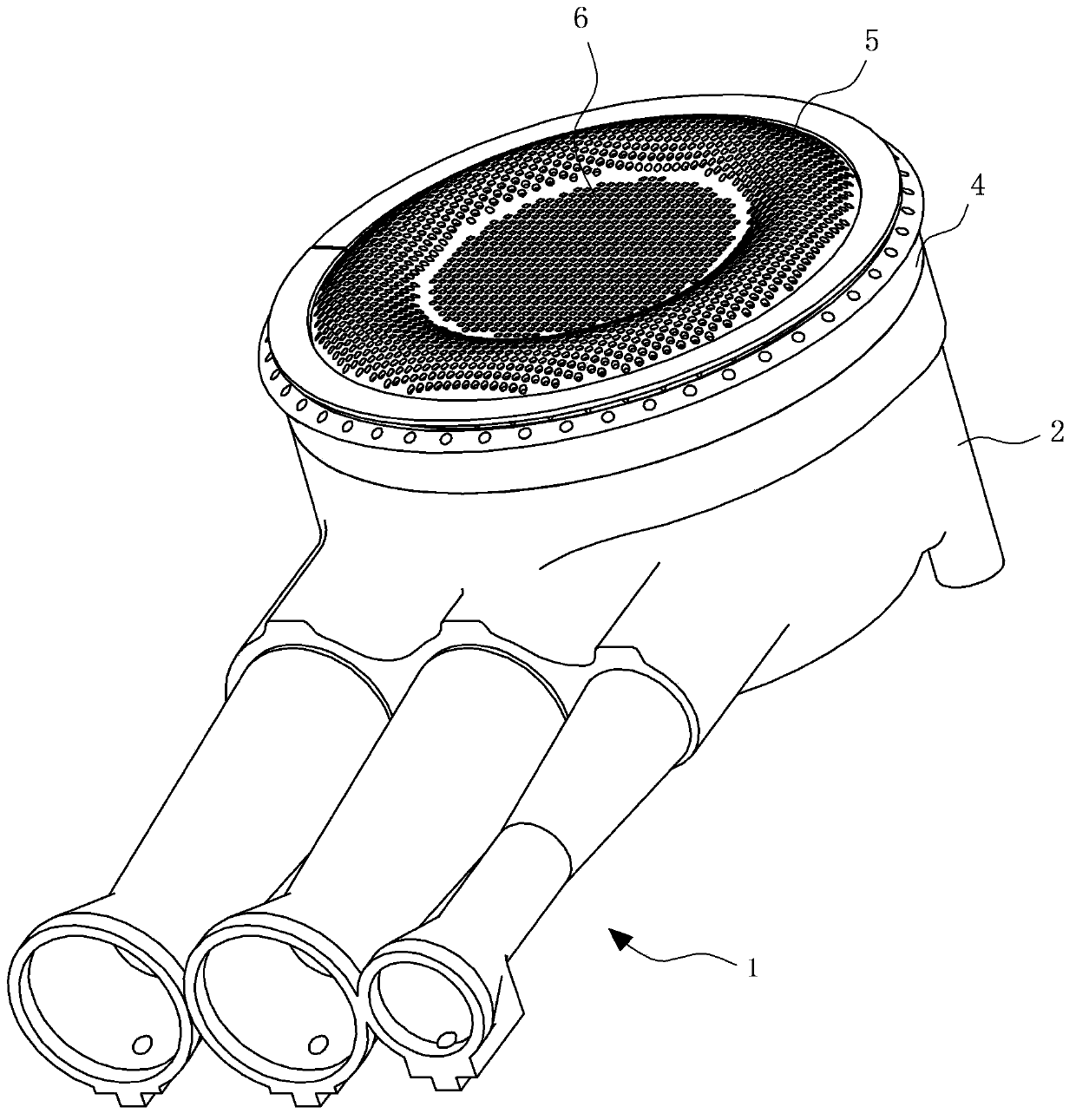

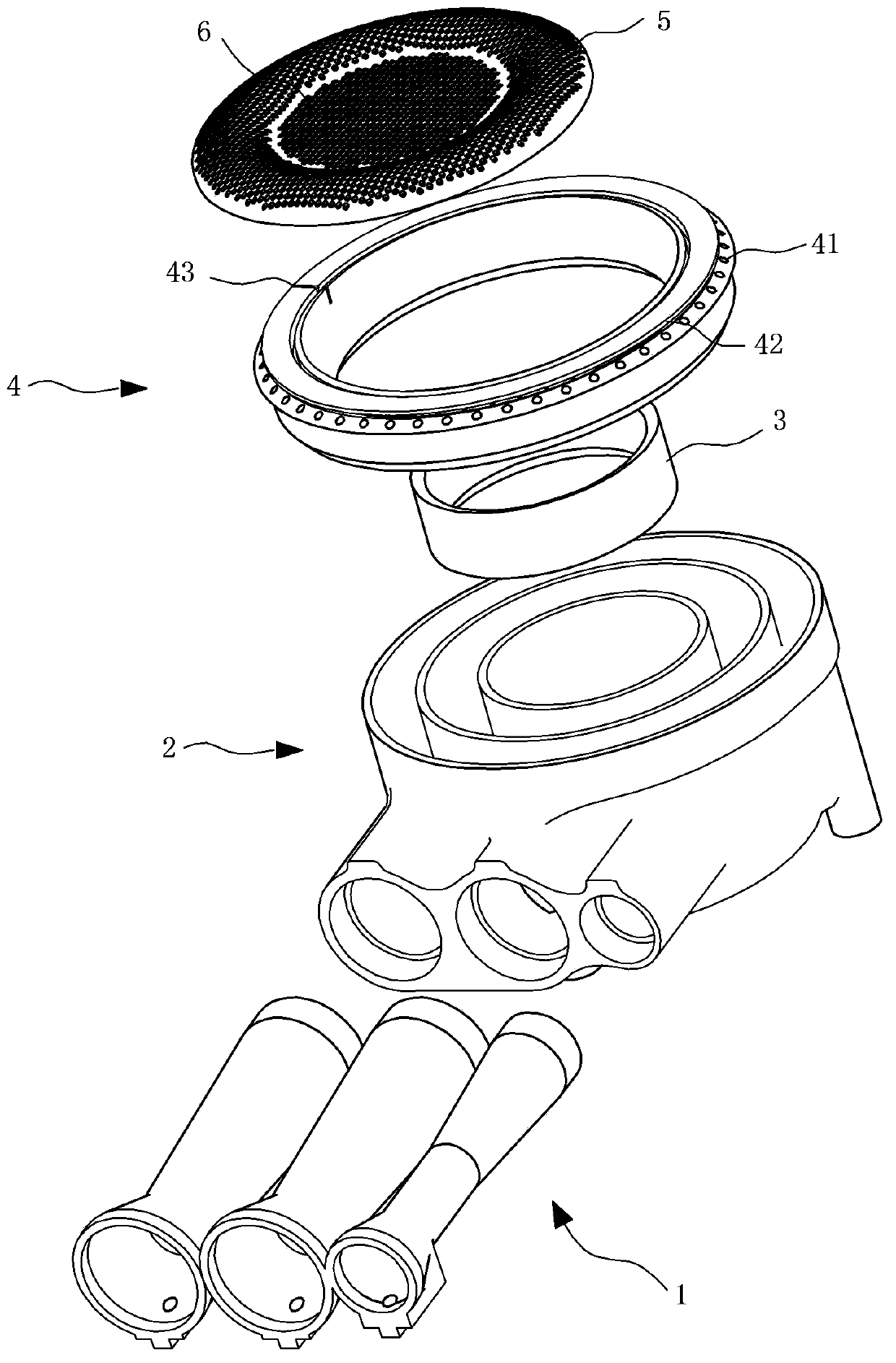

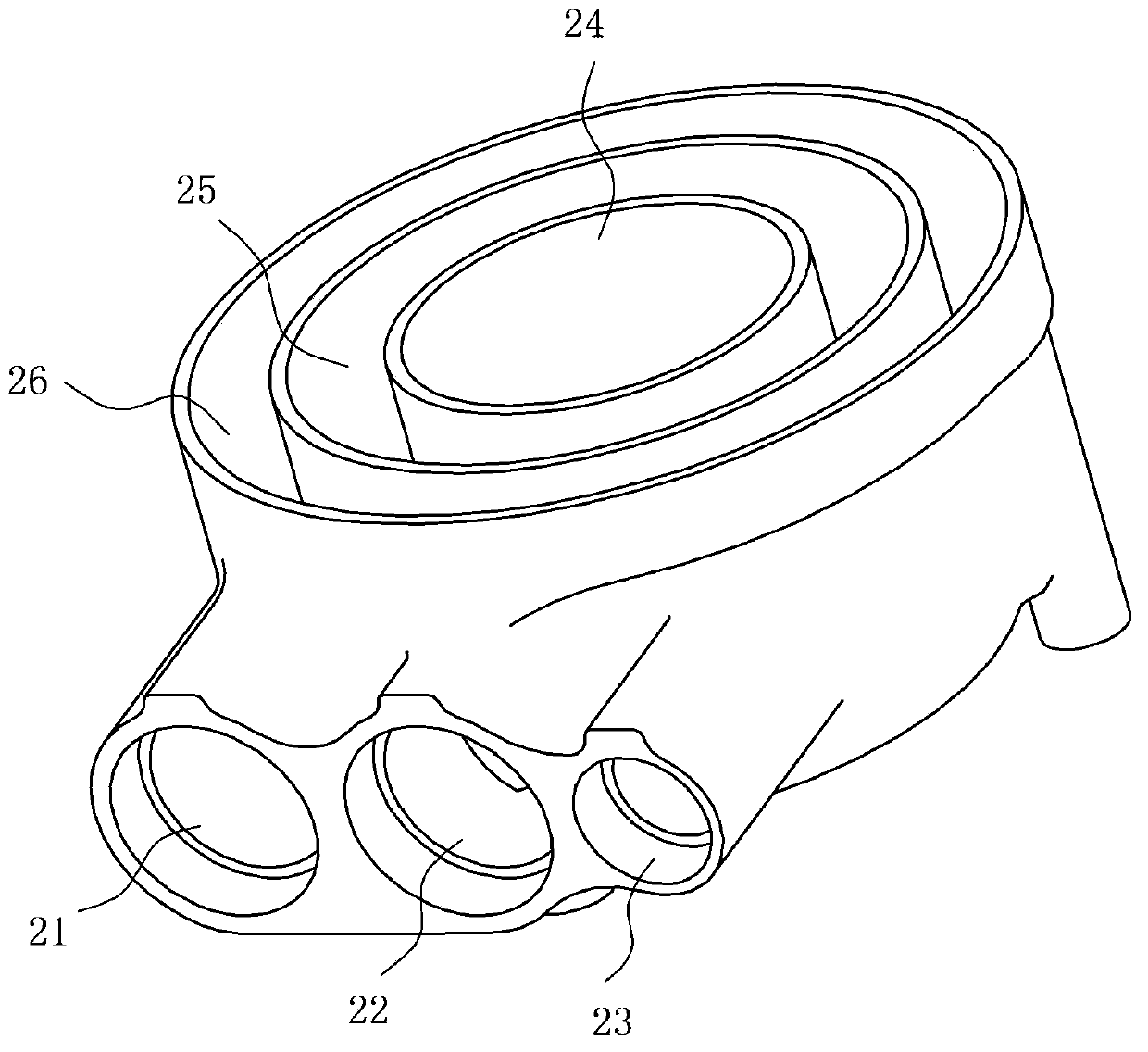

[0030] Figure 1 to Figure 4 The burner of this embodiment includes a body, the body contains a base 2, a mixing chamber is arranged in the base 2, an outer ring fire cover 4 is arranged above the outer ring mixing chamber 26, and an outer ring fire cover 4 is provided on the outer ring fire cover 4. The ring fire hole 41, the outer ring mixing chamber 26 together with the outer ring fire cover 4 form an outer ring flame generator. An infrared burner is arranged inside the body, and the infrared burner includes an inner mixing chamber arranged in the outer ring mixing chamber 26. The inner mixing chamber is provided with a burning plate, and the burning plate is located on the body space surrounded by the outer ring fire cover 4. The combustion plate of the infrared burner can completely fill the body space surrounded by the outer ring fire c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Horizontal angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com