Thermochemical hydrogen production reaction performance evaluation system and thermochemical hydrogen production reaction performance evaluation method based on solar light-concentrating simulator

A technology of solar concentrating and reaction performance, applied in the fields of solar energy utilization and energy storage, can solve the problems of high concentrating temperature, large scale and volume, complicated process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

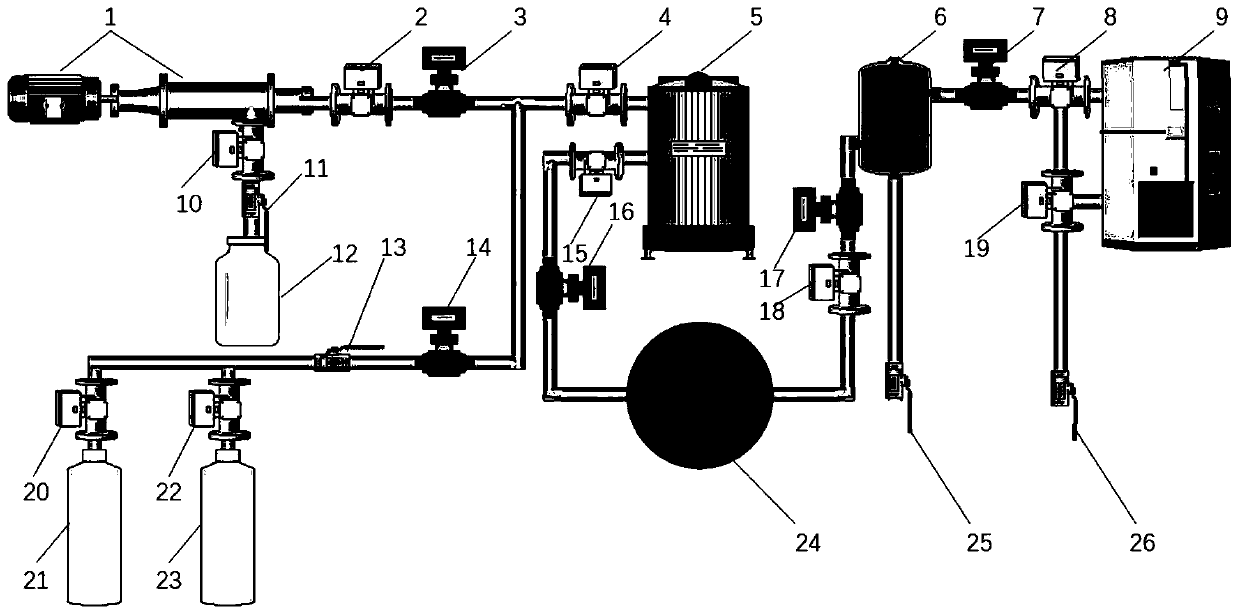

Method used

Image

Examples

Embodiment 1

[0058] Using water and methanol as raw materials, hydrogen is produced by using a thermochemical hydrogen production reaction performance evaluation system based on a solar concentration simulator, and the reaction performance is evaluated. The specific production method is as follows:

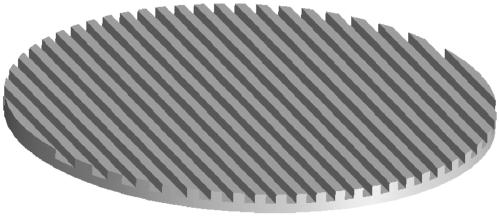

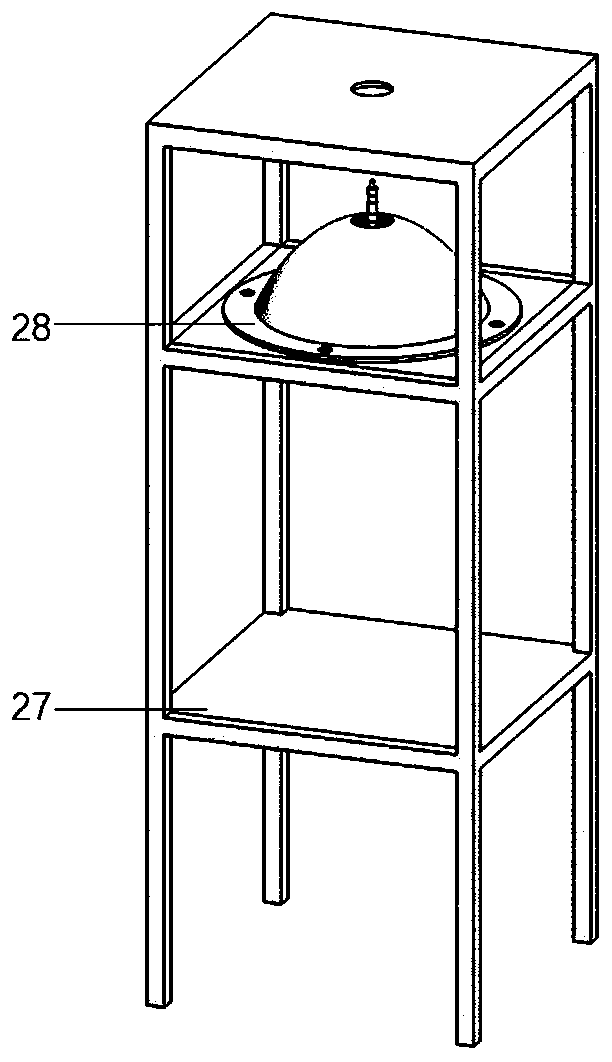

[0059] (1) Pre-experiment preparation: fill the catalyst in the microchannel reactor 24, because methanol steam reforming hydrogen production requires a relatively low temperature between 200-300 degrees Celsius, so the maximum size of the solar concentrating simulator light spot is 5cm to obtain Lower temperature, so catalyst should be filled with all passages, be fixed on the light concentration simulator support 27 after filling, the microchannel reactor is parallel with the light exit port 28 of the light concentration simulator, calibrate the microchannel reactor position, ensure The diameter of the light spot is 5 cm, which completely wraps the microchannel reactor 24 .

[0060] (2) Fee...

Embodiment 2

[0067] Using carbon dioxide and methane as raw materials, the thermochemical hydrogen production reaction performance evaluation system used in the solar concentration simulator is used to produce hydrogen and evaluate the reaction performance. The detailed production method is as follows:

[0068] (1) Preparation before the experiment: fill the catalyst in the microchannel reactor 24, because the reaction temperature requirement of this thermochemical reaction is relatively high, so the distance between the reactor and the second focal point of the solar concentrating simulator should be reduced to obtain Smaller spot, higher energy density, higher temperature. After testing, when the spot diameter is 1.2cm, the temperature can meet the reaction requirements; when the catalyst is filled with the center of the reactor circle as the midpoint, it is filled to form a diameter of 1 cm After the catalyst circle is filled, it is fixed on the light concentration simulator bracket 27. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com