Wide-temperature-range high-performance electrochemical energy storage device based on bismuth-based electrode

An electrochemical and high-performance technology, applied in the field of electrochemical energy storage, can solve problems such as the inability to apply in wide temperature fields, and the inability of bismuth-based electrodes to apply potassium ion batteries, achieving excellent cycle stability, excellent electrochemical performance, and rate performance. super long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

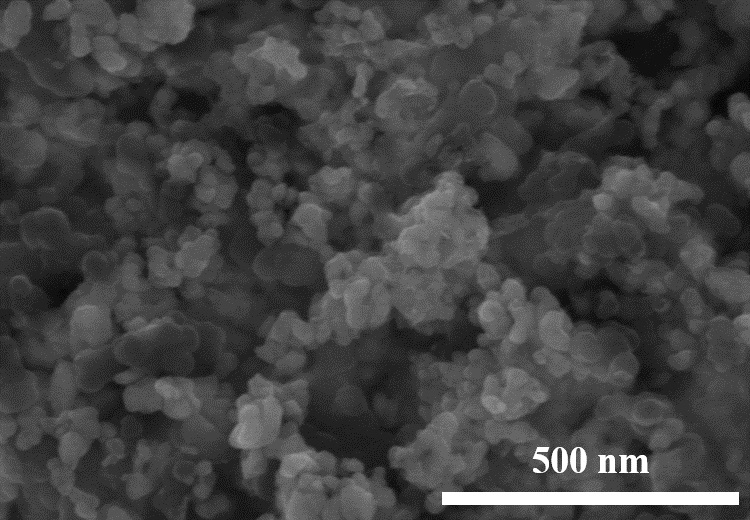

[0042] (1) Weigh 0.1 g of bismuth trichloride powder, dissolve it in 50 ml of methanol, ultrasonic frequency is 30 KHZ, ultrasonic time is 60 minutes, with the help of magnetic stirring, the stirring time is 80 minutes to form S1;

[0043] (2) Weigh 0.08g of sodium borohydride powder, dissolve in methanol solution until complete reaction, the reaction time is 10 minutes, and form S2;

[0044] (3) Pour S1 into S2 under stirring at room temperature. After stirring for 30 minutes, the resulting product was washed with ethanol / methanol / deionized water for several times, and then dried in a vacuum oven at 80︒C for 8 hours. Bismuth material is prepared.

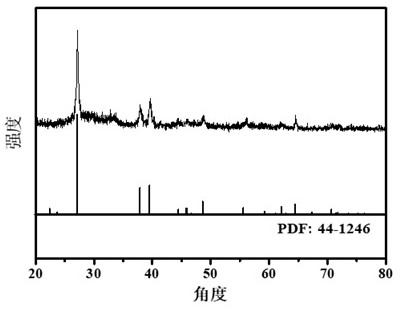

[0045] The phase composition analysis of the prepared bismuth raw materials was carried out by X-ray diffractometer produced by German Bruker company.

[0046] Such as figure 1 As shown, the results show that the peaks at specific positions of this sample correspond to the standard card (PDF-44-1246), respectively. It shows that...

Embodiment 2

[0060] (1) Weigh 0.2 g of bismuth bismuth nitrate pentahydrate powder, dissolve in 60 ml of ethanol, ultrasonic frequency is 10 KHZ, ultrasonic time is 10 minutes, with the help of magnetic stirring, stirring time is 10 minutes to form S1;

[0061] (2) Weigh 0.05g of potassium borohydride powder, dissolve in ethanol solution until complete reaction, the reaction time is 30 minutes, and form S2;

[0062] (3) Pour S1 into S2 under stirring at room temperature, continue stirring for 60 minutes, wash the obtained product with ethanol / methanol / deionized water several times, and then dry it in a vacuum oven at 30︒C for 3 hours. Bismuth material is prepared.

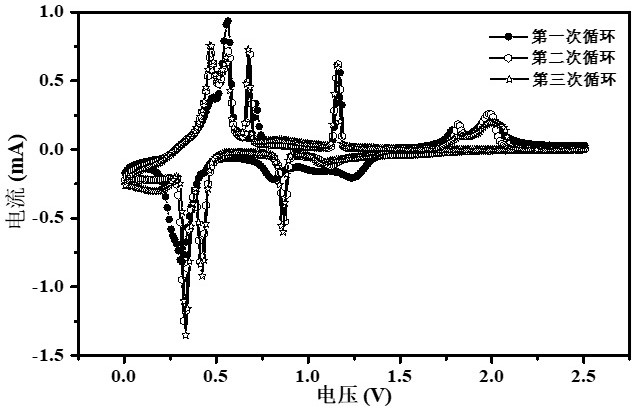

[0063] The manufacturing process of the bismuth electrode is as follows: the binder is dissolved in N-methylpyrrolidone, stirred for 2 h, then the bismuth raw material or carbon material and conductive agent are added to the binder solution, stirred for 6 h, and then coated on the copper foil or aluminum foil, and finally put ...

Embodiment 3

[0067] (1) Weigh 0.5 g of bismuth citrate powder, dissolve it in 70 ml of methanol, ultrasonic frequency is 40 KHZ, ultrasonic time is 200 minutes, with the help of magnetic stirring, the stirring time is 80 minutes to form S1;

[0068] (2) Weigh 0.15g of potassium borohydride powder, dissolve in methanol solution until complete reaction, the reaction time is 100 minutes, and form S2;

[0069] (3) Pour S1 into S2 under stirring at room temperature, continue stirring for 100 minutes, wash the obtained product with ethanol / methanol / deionized water several times, and then dry it in a vacuum oven at 100°C for 15 hours. Bismuth material is prepared.

[0070] The manufacturing process of the bismuth electrode is as follows: the binder is dissolved in N-methylpyrrolidone, stirred for 6 h, then the bismuth raw material or carbon material and conductive agent are added to the binder solution, stirred for 10 h, and then coated on the copper electrode. Foil or aluminum foil, and finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com