A kind of method for preparing polyimide modified phenolic airgel

A polyimide, polyimide precursor technology, applied in the field of foam materials, can solve the problems of poor processing and molding stability, low strength and rigidity, difficult drying methods, etc., to enhance toughness, enhance mechanical properties, The effect of increasing the heat resistance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares polyimide

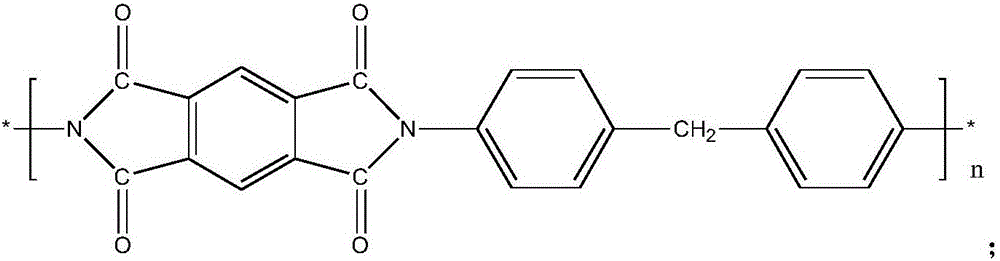

[0027] Dissolve the diamine (the diamine selected in this embodiment is 4,4'-diaminodiphenylmethane) in dimethylacetamide, add pyromellitic dianhydride, the added 4,4'-diamino The molar ratio of diphenylmethane to pyromellitic dianhydride is 1:1.05, stir and react for 4 hours, then add 0.1mL 3-aminopropyltrimethoxysilane dropwise, continue to stir and react for 4 hours, and the reaction product is first washed with deionized water , filtered, washed with distilled water, dried and pulverized at 100°C to obtain polyimide, the obtained polyimide molecular formula is:

[0028]

[0029] In the specific operation, the diamine can also use 4,4'-diaminodiphenyl sulfone, 4,4'-diaminodiphenyl ether, or m-phenylenediamine, and the polyimide obtained by using them as diamine The molecular formula is as follows:

[0030]

Embodiment 2

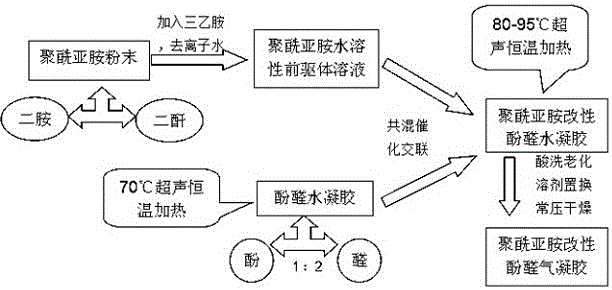

[0032] The raw material components are by weight: 1 part of polyimide obtained in Example 1, 1 part of phenolic mixture (obtained by mixing resorcinol and formaldehyde in a molar ratio of 1:2), a total of 97 parts of deionized water, three 0.5 parts of ethylamine, 0.4 parts of sodium carbonate, and 0.1 parts of 4-dimethylaminopyridine, such as figure 1 Shown:

[0033] (a) polyimide is dissolved in triethylamine and 18 parts of deionized water in proportion to make polyimide precursor solution;

[0034] (b) Dissolve the phenolic mixture into 79 parts of deionized water in proportion, add sodium carbonate and react under a constant temperature of 70°C and a 50KHz ultrasonic environment until it becomes a light red transparent hydrogel to complete the reaction;

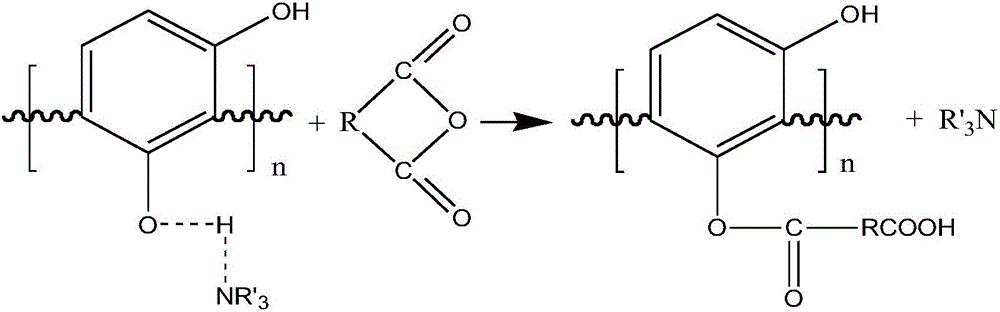

[0035] (c) Add the polyimide precursor solution prepared in step a to the hydrogel obtained in step b, then slowly add 4-dimethylaminopyridine, react at a constant temperature of 95°C and 100KHz ultrasonic environment, ...

Embodiment 3

[0038] The raw material components are by weight: 1 part of polyimide obtained in Example 1, 4 parts of phenolic mixture (obtained by mixing 1,4 hydroquinone and furfural in a molar ratio of 1:2), a total of 94 parts of deionized water part, 0.5 part of triethylamine, 0.4 part of calcium hydroxide, 0.1 part of 4-dimethylaminopyridine;

[0039] (a) polyimide is dissolved in the deionized water of triethylamine and 18 parts in proportion, makes polyimide precursor solution;

[0040] (b) Proportionally dissolve the phenolic mixture into 76 parts of deionized water, add calcium hydroxide and react under a constant temperature of 70°C and a 50KHz ultrasonic environment until it becomes a light red transparent hydrogel to complete the reaction;

[0041] (c) Add the polyimide precursor solution prepared in step a to the hydrogel obtained in step b, then slowly add 4-dimethylaminopyridine, react at a constant temperature of 95°C and 100KHz ultrasonic environment, and wait until it bec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com