Asphalt mixture with ultra-thin overlay

A technology of asphalt mixture and overlay, which is applied in the field of building materials, can solve the problems of low maintenance level and shortage of maintenance funds, and achieve the effects of convenient and fast construction, good skeleton structure, and prevention of early damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

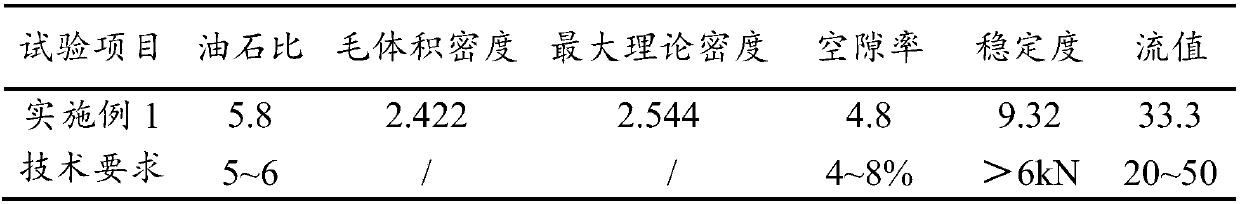

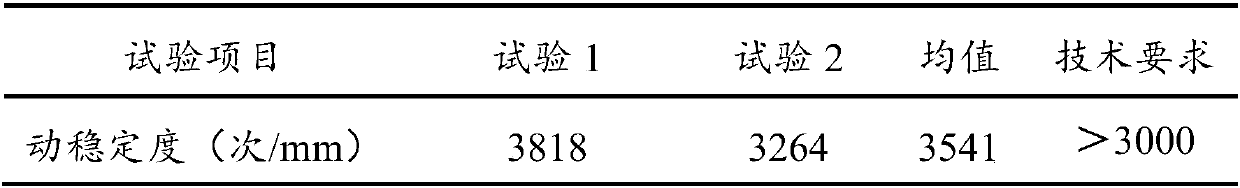

Embodiment 1

[0025] An embodiment of the asphalt mixture for the ultra-thin overcoat layer of the present invention, the asphalt mixture for the ultra-thin overcoat layer in this embodiment comprises the following components in weight percentage: 89.4% of stone material, 4.7% of mineral powder, Bitumen 5.5% and fiber 0.4%;

[0026] The stone is diabase; the stone includes stones with a particle size of 0-3 mm and stones with a particle size of 3-5 mm; the weight percentage of the stones with a particle size of 0-3 mm in the stone is 26 %, the weight percentage of the stone with a particle size of 3-5mm in the stone is 74%.

[0027] The asphalt is Shell PG-76 modified high-viscosity asphalt; the mineral powder is limestone mineral powder; and the fiber is polyester fiber.

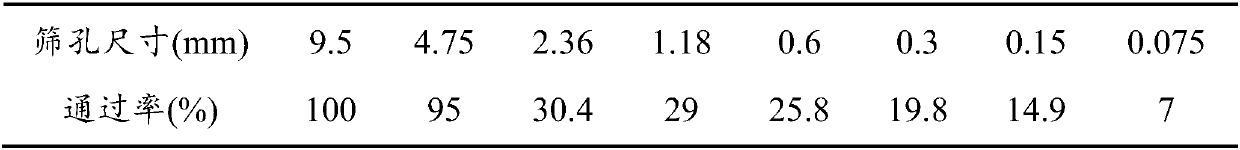

[0028] Synthetic grading refers to the passing rate of the sieve hole of the corresponding size when the stone and mineral powder are added together. The synthetic grading is a more professional expression method than t...

Embodiment 2

[0058] An embodiment of the asphalt mixture for the ultra-thin overcoat layer of the present invention, the asphalt mixture for the ultra-thin overcoat layer in this embodiment contains the following components in weight percentage: 90.02% of stone material, 4.5% of mineral powder, Bitumen 5.1% and fiber 0.38%;

[0059] The stone is granite; the stone includes stones with a particle size of 0-3 mm and stones with a particle size of 3-5 mm; the weight percentage of the stones with a particle size of 0-3 mm in the stone is 24%, The stone with a particle size of 3-5 mm has a weight percentage of 76% in the stone.

[0060] The asphalt is Shell HV modified high-viscosity asphalt; the mineral powder is limestone mineral powder; and the fiber is polyester fiber.

[0061] The synthesis gradation of the ultra-thin overlay asphalt mixture described in this example is shown in Table 9.

[0062] Table 9 Synthetic gradation composition table

[0063]

[0064] After the above material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com