Porous nano-gold carbon nanotube composite material and preparation method thereof

A technology of porous nano-gold and carbon nanotubes, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that are not conducive to the formation of pore structures, excessive agglomeration of nano-gold particles, etc., and achieve enhanced Effects of biocompatibility, prevention of growth and aggregation, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of nanoporous gold-carbon nanotube composite material, the steps are as follows:

[0034] 1) Preparation of porous gold seeds: Dissolve 0.2187g TOAB in 16ml of toluene, after ultrasonic treatment for 30min, add 5ml of chloroauric acid solution (concentration: 10g / L), stir well, weigh 0.001g of short hydroxylated multi-walled carbon nanotubes In the above liquid, stir evenly to obtain solution I. Weigh 0.0760 g of sodium borohydride and dissolve it in 5 ml of deionized water, and stir evenly to obtain solution II. Add solution II dropwise to solution I under stirring condition, wait for the liquid phase to separate after 30 minutes of reaction, and take the upper organic liquid phase for later use.

[0035] 2) Perform solvent heat treatment on the seed crystal: mix the organic liquid phase obtained in step 1) with 20ml toluene and add it into a beaker, stir and mix well, then transfer to the reaction kettle, seal it and put it in an oven, and react at 180°C ...

Embodiment 2

[0038] It is basically the same as Example 1, except that step 1) the mass ratio of chloroauric acid and hydroxylated carbon nanotubes is 25:1, the mass ratio of TOAB and chloroauric acid is 5:1, and the concentration of TOAB in solution I is 0.016mol / L; The volume ratio of organic liquid phase to toluene is 1:2. The solvothermal reaction condition of step 2) is: constant temperature reaction at 160° C. for 10 h.

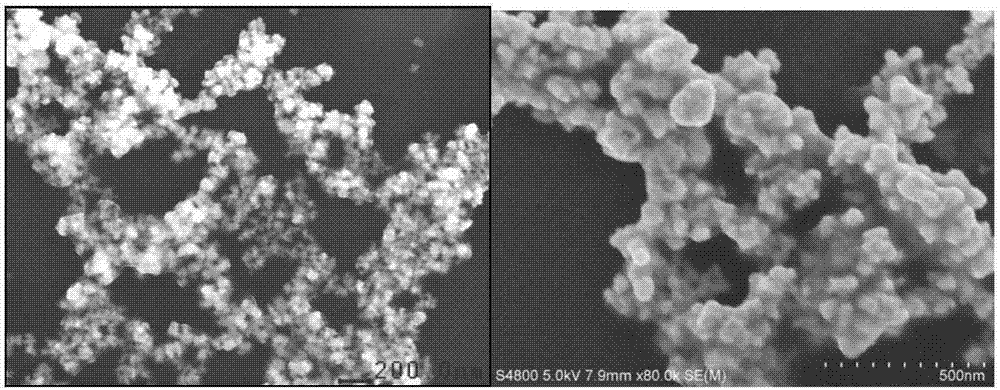

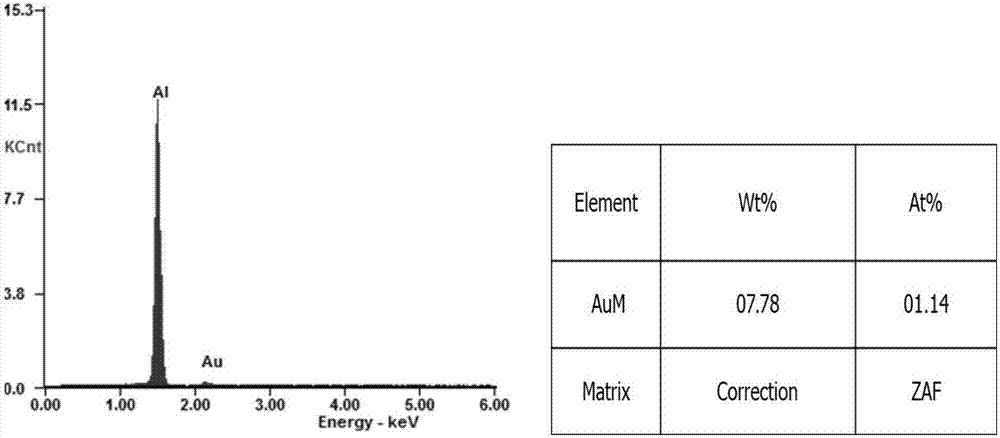

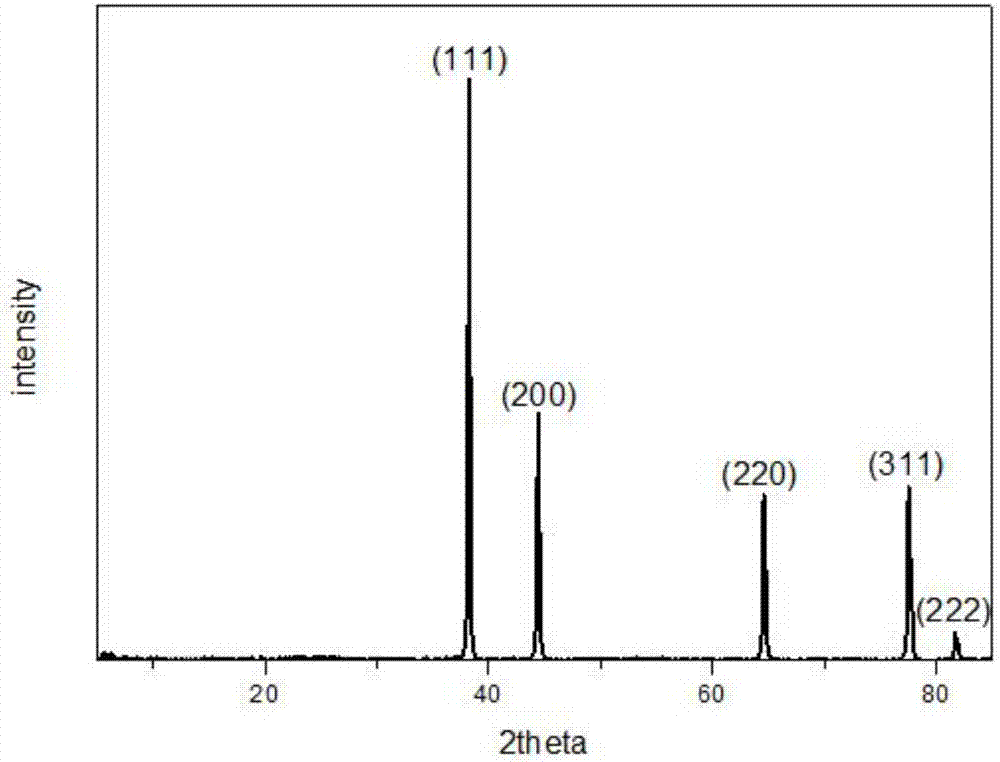

[0039] The synthesized product is characterized as similar to Example 1. Figure 6The SEM image of the product obtained for Example 2, Figure 7 XRD pattern of the product obtained for Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com