Preparation method of hydrogen sulfide gas sensor material with biomass-loaded inorganic particles as well as product and application thereof

An inorganic particle, gas sensing technology, applied in inorganic chemistry, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of reduced device life, high cost, and high operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

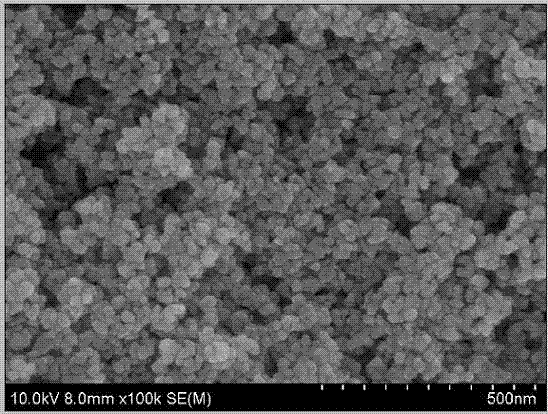

[0022] Weigh 0.05mol and 0.025mol of ferric chloride and cobalt chloride precursors and dissolve them in 100ml of deionized water and stir evenly at 300rpm to obtain solution A; continue to weigh 0.2mol of sodium hydroxide and dissolve in 100ml of deionized water and stir to dissolve Obtain solution B; add solution B dropwise to solution A with constant stirring and heat to 90 o C reacts for 30min to obtain CoFe 2 O 4 After centrifugation, washing and drying, the sediment is collected for 5 o C / min heating up to 500 o C, the nano-powder that naturally cools down after heat preservation for 2h, see figure 1 The nano CoFe prepared in Example 1 2 O 4 Scanning electron microscope photos.

[0023] Weigh 9g of modified starch granules and dissolve them in deionized water, add 0.5g of glycerin after complete dissolution, and continuously stir until clear, then add 0.5g of CoFe 2 O 4 In an organic solution, and then form a film on the spin coater, the excess water is 60 o C is evaporated i...

Embodiment 2

[0025] Weigh 0.05mol and 0.025mol of ferric chloride and cobalt chloride precursors and dissolve them in 100ml of deionized water and stir evenly at 300rpm to obtain solution A; continue to weigh 0.2mol of sodium hydroxide and dissolve in 100ml of deionized water and stir to dissolve Obtain solution B; add solution B dropwise to solution A with constant stirring and heat to 90 o C reacts for 30min to obtain CoFe 2 O 4 After centrifugation, washing and drying, the sediment is collected for 5 o C / min heating up to 500 o C, Nano powder that naturally cools down after 5 hours of heat preservation, see figure 1 .

[0026] Weigh 9g of modified starch granules and dissolve them in deionized water, add 0.5g of glycerin after complete dissolution, and continuously stir until clear, then add 0.5g of CoFe 2 O 4 In the organic solution, then the film is formed on the spin coater, the excess water is 80 o C is evaporated in vacuum to obtain a 200μm film. The obtained film was glued to the hexa...

Embodiment 3

[0028] Weigh 0.1 mol and 0.05 mol of the precursors of ferric chloride and cobalt chloride and dissolve them in 100 ml of deionized water and stir evenly at 300 rpm to obtain solution A; continue to weigh 0.45 mol of sodium hydroxide and dissolve in 100 ml of deionized water and stir to dissolve Obtain solution B; add solution B dropwise to solution A with constant stirring and heat to 90 o C reacts for 30min to obtain CoFe 2 O 4 After centrifugation, washing and drying, the sediment is collected for 5 o C / min heating up to 500 o C, the nanopowder that naturally cools down after holding for 3.5 hours, see figure 1 .

[0029] Weigh 8.5g of modified starch granules and dissolve them in deionized water, add 0.5g of glycerin after complete dissolution, and continue stirring until clear, and then add 1g of CoFe 2 O 4 In an organic solution, and then form a film on the spin coater, the excess water is at 70 o C evaporated in vacuum to obtain a 150μm film. The obtained film was glued to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com