Outdoor alternating current high-voltage SF6 automatic sectionalizer

An automatic sectionalizer and SF6 technology, which is applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve problems such as switches not working properly, and achieve the effect of good pressure difference resistance and wide application temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

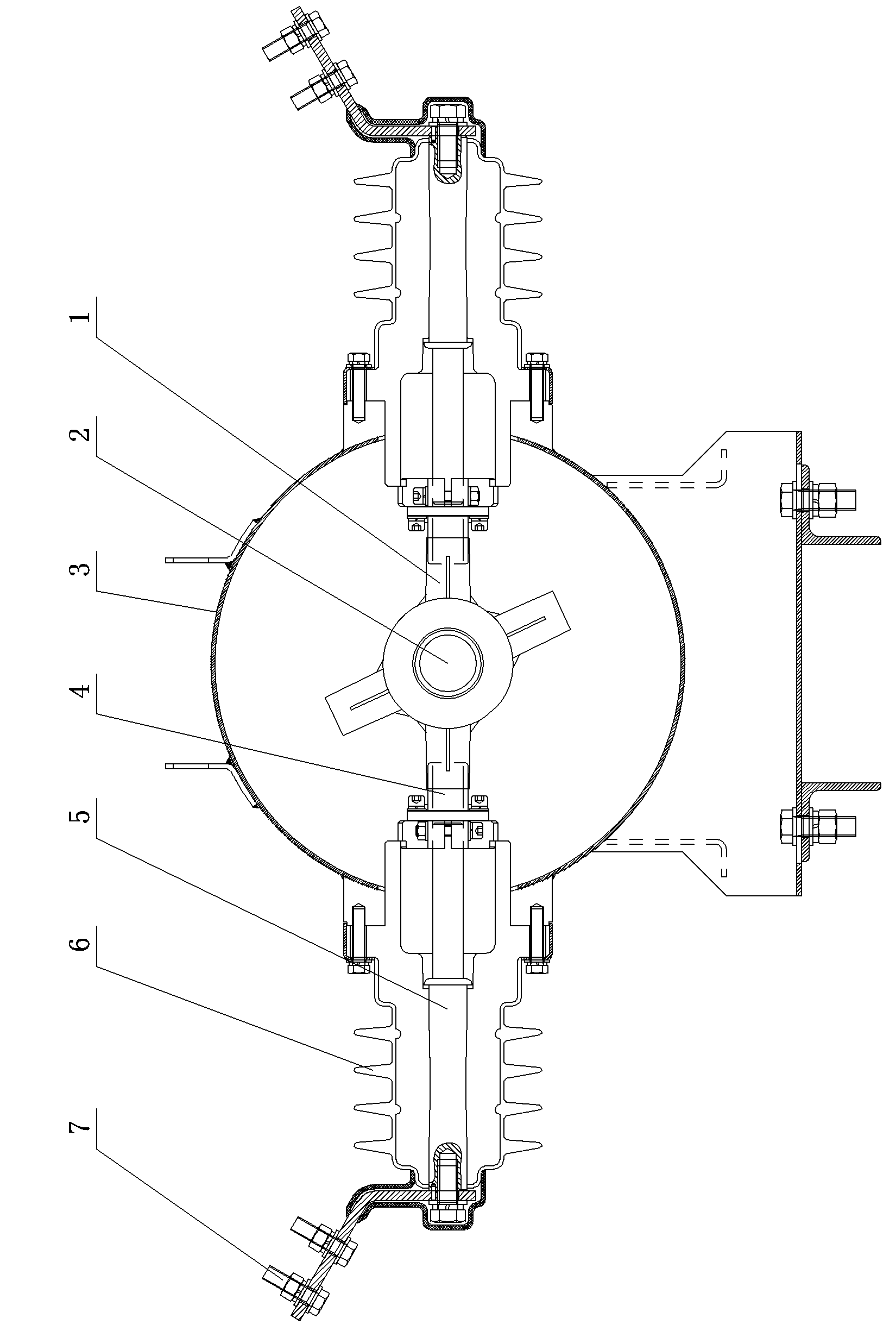

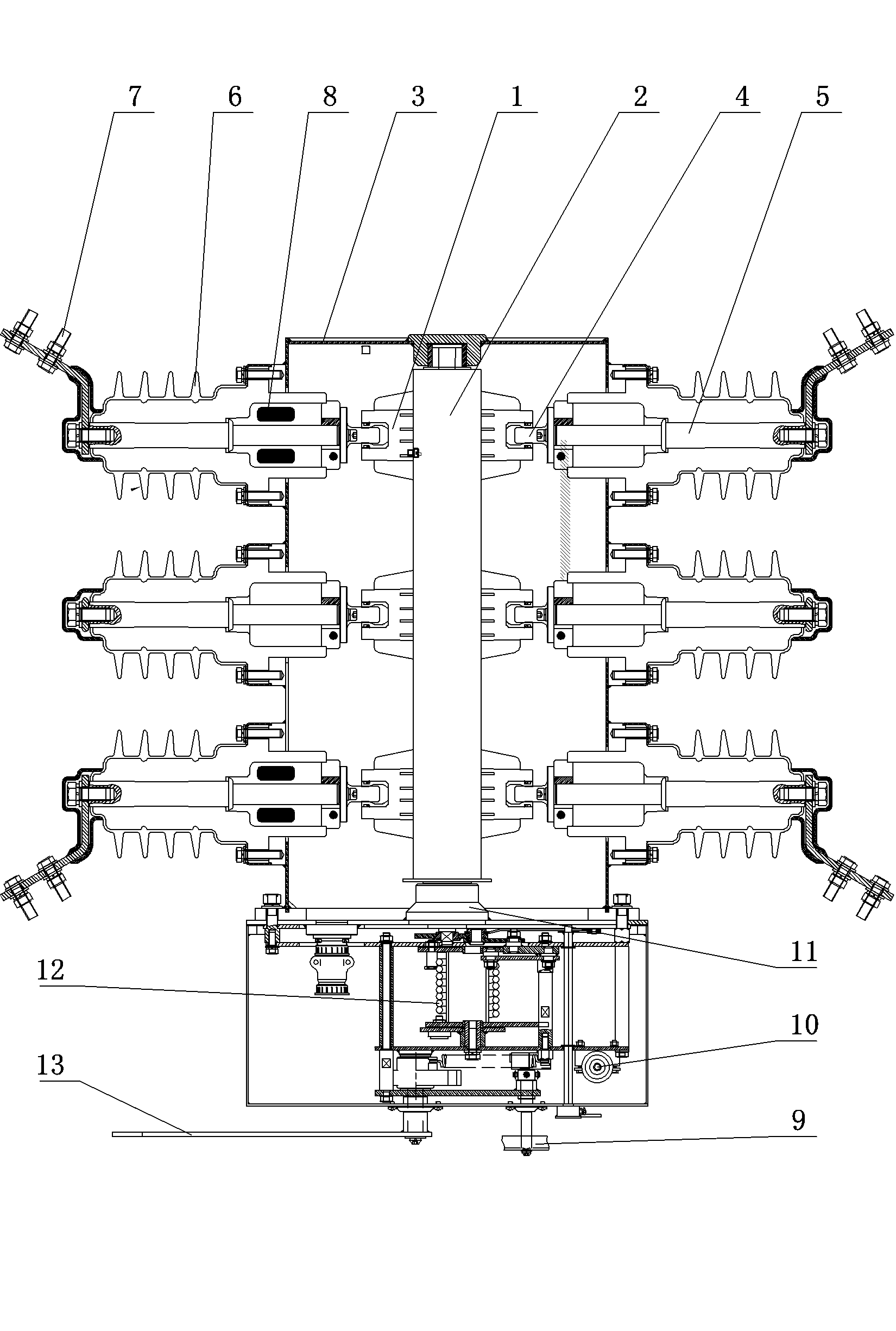

[0022] Such as figure 1 As shown, the present invention includes a box body 3, which is filled with SF6 gas, the middle part of the box body 3 is provided with a rotating shaft 2, and the rotating shaft 2 is provided with a movable contact 1; the box body 3 is provided with an insulator 6, and one end of the insulator 6 It extends into the box body 3 and is provided with a static contact 4 corresponding to the moving contact 1. The other end of the insulator 6 is provided with a terminal 7. The terminal 7 is connected to the static contact 4 through a conductive rod 5. One end of the rotating shaft 2 is passed through a magnetic fluid. The sealing shaft head 11 is connected with the spring mechanism 12 that drives the rotating shaft 2 to rotate outside the box body 3. The energy storage handle 13 that drives the spring mechanism 12 and the opening and closing electric tripper 10 are arranged on the outside of the spring mechanism 12. The opening and closing electric release ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com