Method and device for preparing H2 and separating CO2 based on calcium-based sorbent

A calcium-based absorbent and CO2 technology, applied in hydrogen separation, hydrogen separation using solid contact, hydrogen production, etc., can solve the problems of increasing system complexity and investment costs, limited hydrogen purity, incomplete reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Configure CaO / Al with different mass ratios (100:0, 80:20, 70:30, 60:40, 50:50) 2 o 3 Mixture, Al 2 o 3 As an inert carrier, on the one hand, it can provide a suitable void structure for the calcium-based absorbent, on the other hand, it can also increase the wear resistance of the calcium-based absorbent and prolong the life of the calcium-based absorbent.

[0029] Send the mixture of calcium-based absorbent and coal powder with a mass ratio of 2.5kg / kg into the gasification reactor 1-5 through the screw feeder 1-4, and heat the bed temperature of the gasification reactor 1-5 to 700°C , 3888kg / h water vapor is introduced from the bottom of gasification reactor 1-5, the temperature of the imported water vapor is 500°C, coal reacts with water vapor to produce water gas, and the water gas composition includes H 2 、CH 4 , CO, CO 2 gas, CH 4 Reforming reaction with water vapor to generate CO and H 2 , CO undergoes a shift reaction with water vapor to form CO 2 and H...

Embodiment 2

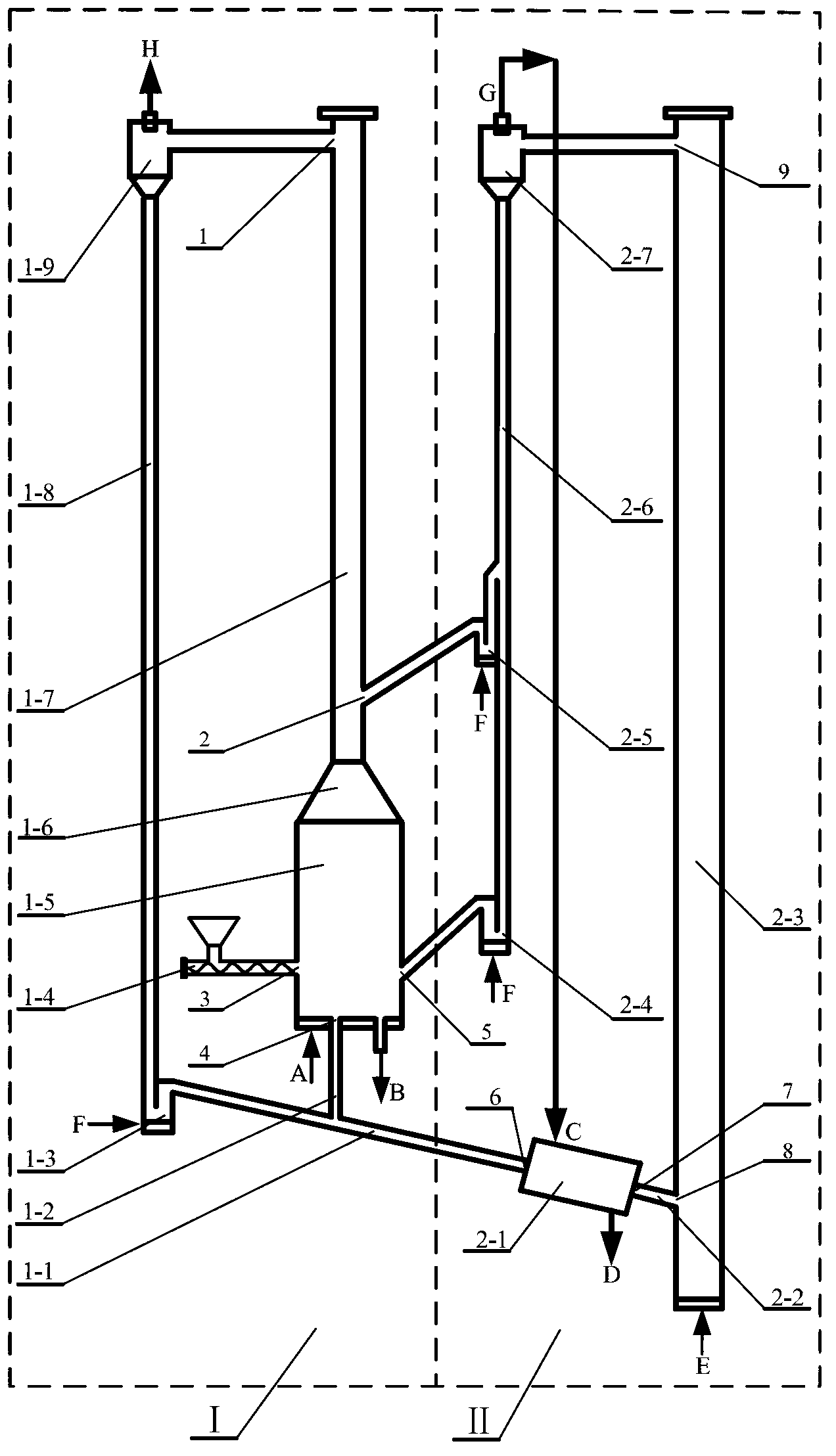

[0033] The device adopted in the present invention consists of a first inclined pipe 1-1, a feeding pipe 1-2, a first return valve 1-3, a screw feeder 1-4, a gasification reactor 1-5, a gasification reaction Transition section 1-6, absorption reactor 1-7, first standpipe 1-8, first cyclone separator 1-9, preheater 2-1, second inclined pipe 2-2, calcining reactor 2 -3. The second material return valve 2-4, the third material return valve 2-5, the second standpipe 2-6, and the second cyclone separator 2-7.

[0034] The lower part of the gasification reactor 1-5 is provided with a feed port 3 and a return port 5, the gasification reactor feed port 3 is connected with the screw feeder 1-4, and the gasification reactor return port 5 is connected with the second return port. Material valve 2-4 is connected, the top of gasification reactor 1-5 is connected with the bottom of absorption reactor 1-7 through gasification reactor transition section 1-6, and the bottom of gasification rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com