Preparation method and application of mixed matrix membrane with thermoplastic elastomer as matrix

A thermoplastic elastomer, mixed matrix membrane technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., to achieve excellent separation performance, break through the effect of compromise relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

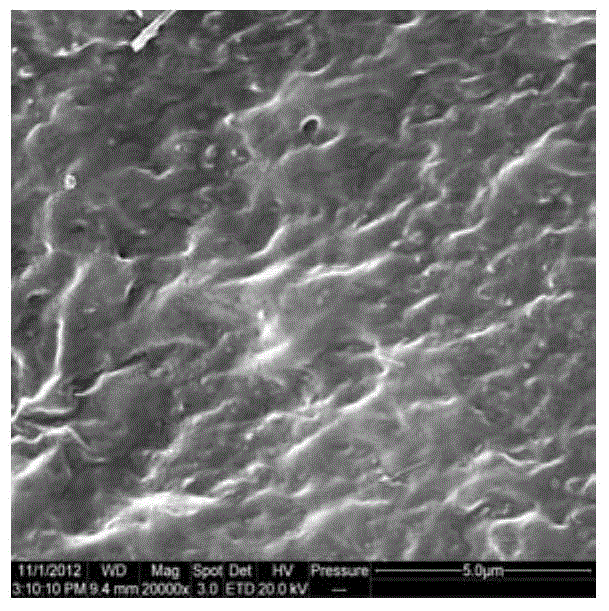

[0041] Weigh a certain amount of Pebax particles and add them to acetic acid, stir at ~50°C for 6 hours to prepare a uniform and transparent 5wt% Pebax solution, let it stand overnight for degassing, then cast the solution onto a PTFE plate, and evaporate the solvent at room temperature After the film is formed, peel it off and put it in an oven at 60°C for at least 24 hours to remove the solvent, then transfer the film to a vacuum oven at 70°C to dry for at least 48 hours, continue to remove the residual solvent, and finally obtain a pure Pebax film, the structure of which is shown in figure 2 .

[0042] Test the gas permeability of the pure Pebax membrane. See Table 1 for the test results at 35°C and an inlet pressure of 0.3MPa.

[0043] Table 1 Gas permeation properties of pure Pebax membranes

[0044]

Embodiment 2

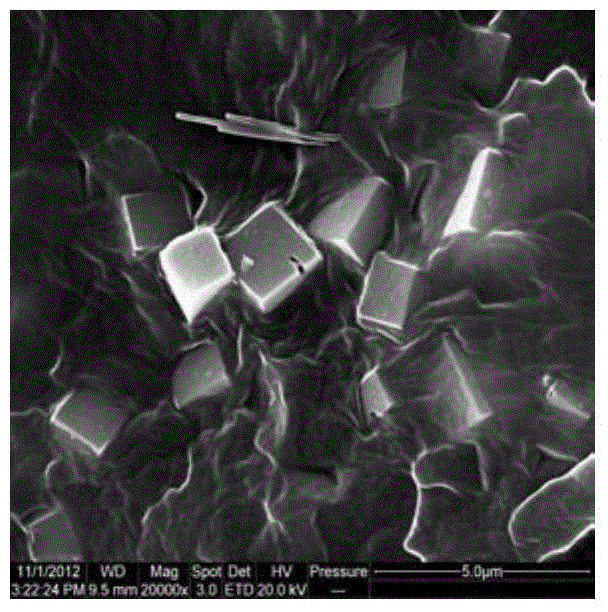

[0046] Prepare a Pebax acetic acid solution with a certain concentration (≤5wt%) as described in Example 1, add SAPO-34 with 30% polymer mass, stir for pre-dispersion and ultrasonication for 2 hours, then continue to stir for at least 2 hours, and then cast the mixed solution to On the PTFE plate, the mixed solution was ultrasonicated for 10 minutes before casting, and the solvent was evaporated at room temperature. After the film was formed, it was peeled off and placed in a 60°C oven for at least 24 hours to remove the solvent, and then the film was transferred to a 70°C vacuum oven for drying. At least 48h, continue to remove the residual solvent to obtain a Pebax / SAPO-34 (10 / 3) mixed matrix membrane.

[0047] The gas permeability of the Pebax / SAPO-34 (10 / 3) mixed matrix membrane was tested. The test results at 35°C and an inlet pressure of 0.3MPa are shown in Table 2.

[0048] Table 2 Pebax / SAPO-34 (10 / 3) gas permeability properties of mixed matrix membranes

[0049]

Embodiment 3

[0051] Prepare a Pebax acetic acid solution with a certain concentration (≤5wt%) as described in Example 1, add SAPO-34 with 50% polymer mass, stir for pre-dispersion and ultrasonication for 2 hours, then continue stirring for at least 2 hours, and then cast the mixed solution to On the PTFE plate, the mixed solution was ultrasonicated for 10 minutes before casting, and the solvent was evaporated at room temperature. After the film was formed, it was peeled off and placed in a 60°C oven for at least 24 hours to remove the solvent, and then the film was transferred to a 70°C vacuum oven for drying. At least 48h, continue to remove the residual solvent to obtain a Pebax / SAPO-34 (10 / 5) mixed matrix membrane.

[0052] The gas permeability of the Pebax / SAPO-34 (10 / 5) mixed matrix membrane was tested, and the test results at 35°C and an inlet pressure of 0.3 MPa are shown in Table 3.

[0053] Table 3 Gas permeability of Pebax / SAPO-34(10 / 5) mixed matrix membrane

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com