A kind of concentrated runner adsorption material and its preparation method

A technology of adsorption materials and concentrated runners, which is applied in the field of adsorption materials, can solve the problems of low stability, not easy to peel off, service life, and low efficiency, and achieve the effects of low wind resistance, high molecular sieve content, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

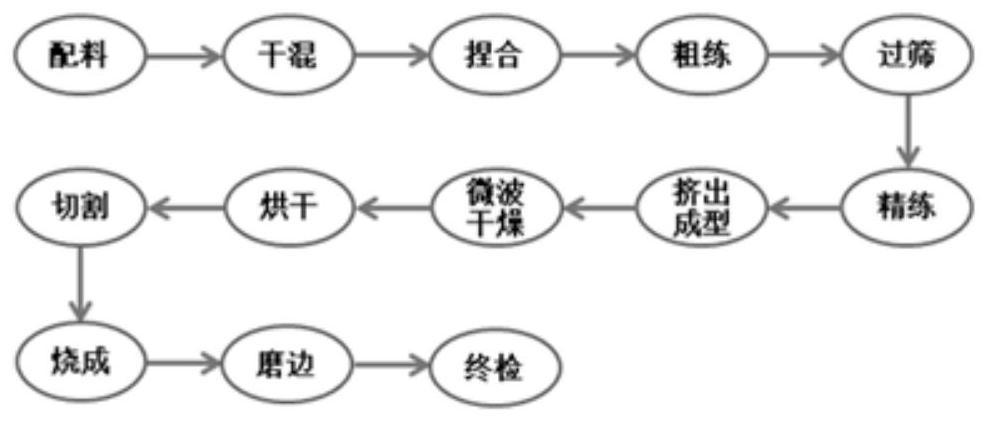

[0042] The process steps for preparing the concentrated runner adsorption material are as follows:

[0043] (1) Prepare raw materials:

[0044] The weight percent of inorganic powder: 75% high silicon type zeolite molecular sieve ZSM-5 (hereinafter abbreviated as ZSM-5), 12.5% active alumina precursor of D50=0.98 μ m, 12.5% fumed silica (D50 =9.23μm, specific surface 150m 2 / g).

[0045] Taking the inorganic powder as 100 parts by weight, take 8 parts by weight of methylcellulose, 2.67 parts by weight of polyether polyol, 2.67 parts by weight of soybean oil, and water of 30 parts by weight, and mix;

[0046] (2) After fully dry mixing, kneading, and vacuum refining, extrude into a molecular sieve runner sample block of 40×40×130mm, 400 holes / square inch, and a wall thickness of 7mil. After drying, use the molecular sieve runner in Table 1 to quickly burn According to the curve, after firing at 550°C for 4 hours, the firing shrinkage is 2.1%.

[0047] In the roasting st...

Embodiment 2

[0058] (1) Prepare raw materials:

[0059] The weight percentage of inorganic powder: 80% of ZSM-5, 10% of D50 = 0.98μm active alumina precursor, 10% of D50 = 9.23μm, specific surface area is 380m 2 / g of fumed silica mixed;

[0060] Taking the inorganic powder as 100 parts by weight, take 8 parts by weight of methylcellulose, 2.67 parts by weight of polyether polyol, 2.67 parts by weight of soybean oil, and 30 parts by weight of water, and mix them uniformly;

[0061] (2) After fully dry mixing, kneading, and vacuum refining, extrude into a molecular sieve runner sample block of 40×40×130mm, 400 holes / square inch, and a wall thickness of 7mil. After drying, use Table 1: Molecular sieve runner fast Sintering curve, after sintering at 550° C. and heat preservation for 4 hours (see Example 1 for the technical parameters of sintering, the following examples are all the same without special instructions), the firing shrinkage is 2.1%.

[0062] The performance of the concentratio...

Embodiment 3

[0065] (1) Prepare raw materials:

[0066] The weight percent of inorganic powder: 90% of ZSM-5, 5% of D50=0.98μm active alumina precursor, 5% of D50=9.23μm, specific surface area is 220m 2 / g of fumed silica mixed;

[0067] Taking the inorganic powder as 100 parts by weight, take 8 parts by weight of methyl cellulose, 2.67 parts by weight of polyether polyol, 2.67 parts by weight of soybean oil, and 30 parts by weight of water, and mix uniformly;

[0068] (2) After fully dry mixing, kneading, vacuum mud refining, refining and kneading mud into mud section;

[0069] (3) Extrude the plastic mud section into a 40×40×130mm, 400 holes / square inch, 7mil honeycomb structure molecular sieve runner sample block, and then carry out microwave;

[0070] (4) The green body after the microwave is cut to a fixed height, then dried, and the firing curve is shown in Table 1, and the firing shrinkage is 2.0%, and the specific process parameters of firing are shown in Example 1;

[0071] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com