Preparation method for honeycomb supported catalyst containing coating of molecular sieve composition

A technology of honeycomb carrier and molecular sieve, which is applied in the field of honeycomb carrier catalyst preparation, can solve the problems of difficulty in increasing the molecular sieve content in the coating, the coating is easy to fall off, and the gasoline conversion activity is not high, so that it is not easy to crack and fall off, the coating is firm, Substrate properties have little influence on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

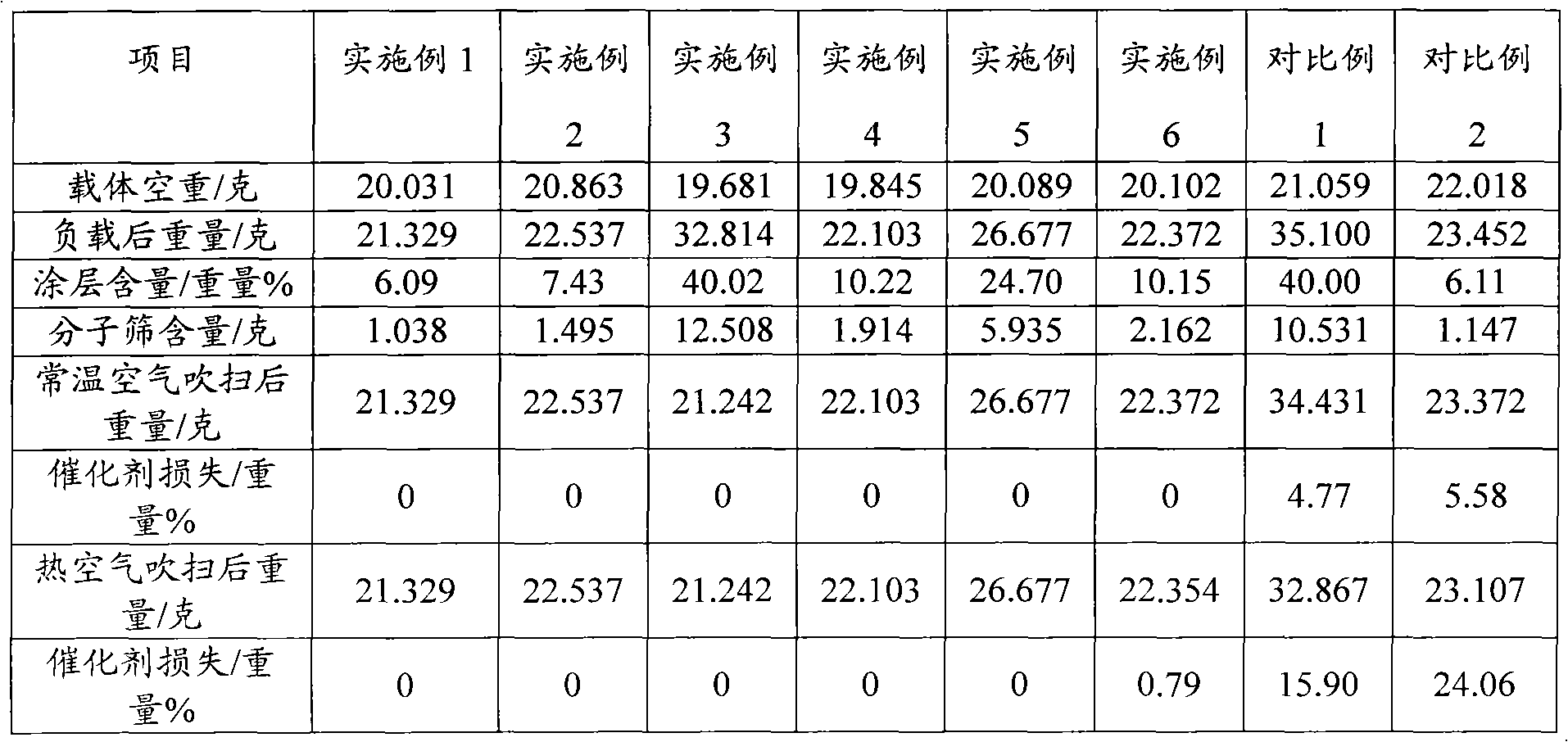

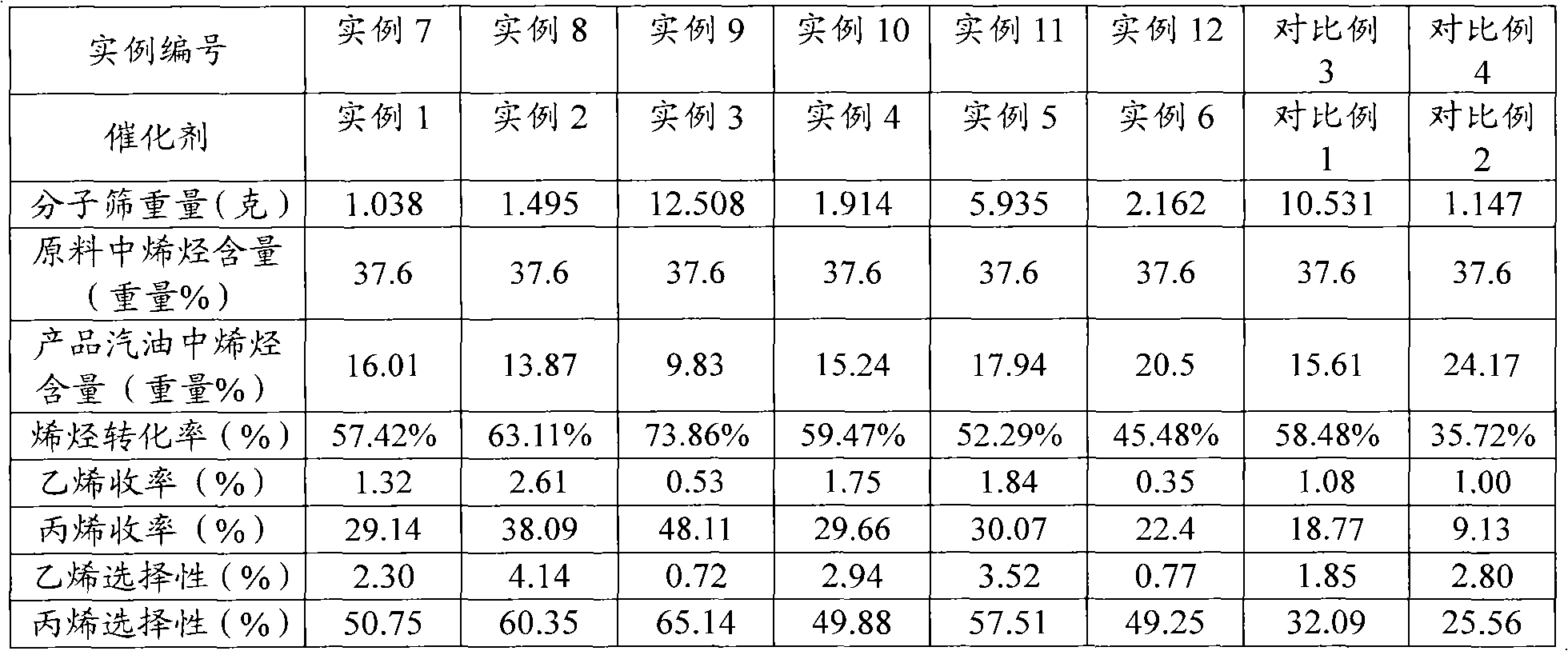

Examples

preparation example Construction

[0011] In the method for preparing a honeycomb carrier catalyst containing a molecular sieve composition coating provided by the present invention, the coating slurry is preferably prepared by a method comprising the following steps:

[0012] (1) mixing the molecular sieve with water and grinding to obtain a molecular sieve slurry having a molecular sieve particle diameter d90 of 1 to 10 microns;

[0013] (2) The molecular sieve slurry obtained in step (1), the phosphoraluminum glue and / or the precursor material that can form the phosphoraluminum glue and the dispersant solution are mixed, with or without adding clay; wherein, the content of the dispersant in the dispersant solution It is 1~10% by weight, the particle diameter of phosphoraluminum glue and the precursor material that can form phosphoraluminum glue are all less than 100nm, preferably 1~90nm, more preferably 1~60nm, average particle diameter is preferably 5~70nm, more preferably 5-30nm.

[0014] Wherein, in the ...

example 1

[0022] Mix 108 grams (on a dry basis, the same below) of HY-type molecular sieve powder (d90=14 microns, industrial grade, product of Sinopec Catalyst Qilu Branch) with 120.5 grams of deionized water, and wet ball mill it into a molecular sieve slurry. d90=5 microns, add 128 grams of phosphoraluminum glue in the slurry (preparation method: make a slurry of pseudoboehmite and decationized water, add concentrated phosphoric acid with a concentration of 85% by weight under stirring, and heat up to 70°C for 1 hour to prepare Obtain. Wherein contain phosphorus oxide 18% by weight, aluminum oxide 3% by weight, pH value is 1.2, particle diameter is 27~55nm, and average particle diameter is 32nm), the add-on of phosphorus aluminum glue is 25% by weight of molecular sieve weight, stir 10 minutes, add polyethylene glycol solution 3.24 grams (the weight percent of polyethylene glycol is 2 weight %), the addition of this solution is 3 weight % of molecular sieve weight, stir 20 minutes to ...

example 2

[0026] 120 grams of rare earth Y-type molecular sieve powder (d90=12 microns, RE 2 o 3 Content 3% by weight, product of Sinopec Catalyst Qilu Branch) mixed with 261 grams of deionized water, wet ball milled into a slurry, molecular sieve particle diameter d90=8 microns in the slurry; Make a slurry of aluminum and decationized water, add concentrated phosphoric acid with a concentration of 85% by weight under stirring, heat up to 60°C and react for 1 hour; it contains 10% by weight of phosphorus pentoxide, 5% by weight of aluminum oxide, and the pH value is 2.0 , particle diameter is 43 ~ 72nm, average particle diameter is 58nm), with P 2 o 5 and Al 2 o 3 The total weight of the phosphorus-aluminum glue add-on is 12% by weight of the molecular sieve weight, and stirred for 15 minutes; 12 grams of polyacrylic acid solution was added (the polyacrylic acid content is 1% by weight), and the polyacrylic acid solution add-on was 10% by weight of the molecular sieve weight, Stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com