Method for preparing olefins by catalytic cracking of light oil

A technology for catalytic cracking and olefin production, which is applied in the fields of hydrocarbon cracking and hydrocarbon production, chemical instruments and methods, molecular sieve catalysts, etc. Close, good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

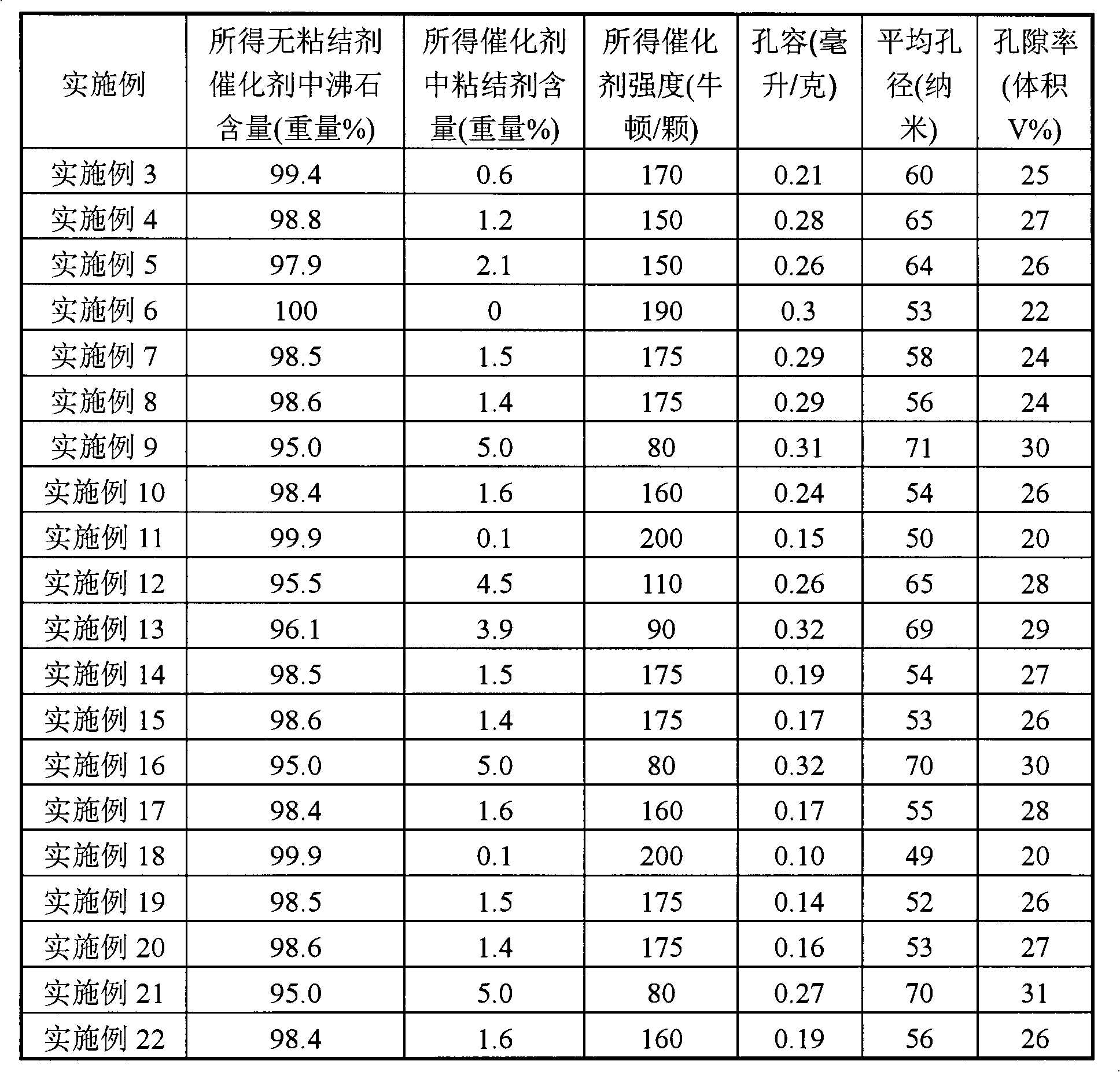

[0027] Take 60 grams of ZSM-5 molecular sieve with a silicon-aluminum ratio (molecular ratio, the same below) of 30, add 40 grams of silica sol with a weight percentage of 40%, mix and stir evenly, and then add 1 mol / liter of sodium hydroxide The solution is 10 ml, mixed and stirred evenly, and then the agent bar is formed, and the formed catalyst is dried at 80°C for 3 hours, and then put into an autoclave containing water at the bottom of the liner. The catalyst and liquid water are not in contact. After crystallization at 170°C for 60 hours, take it out, then wash it twice, put it in an oven for 3 hours at 120°C, put it into a muffle furnace and bake it at 400°C for 2 hours, then at 550°C for 3 hours to obtain non-sticky Binder ZSM-5 catalyst. The XRD spectrum of the prepared catalyst shows a pure ZSM-5 phase. The scanning electron microscope picture of the prepared catalyst shows pure ZSM-5 crystal grains, and there is almost no binder in the amorphous state. The crushin...

Embodiment 2

[0029] According to the method of Chinese patent CN101428233A, the ZSM-5 / beta zeolite mixed crystal molecular sieve with a silicon-aluminum ratio of 40 is prepared. Take 60 grams of ZSM-5 / beta zeolite, add 40 grams of silica sol with a weight percentage of 40%, mix and stir evenly, then add 2 grams of magnesium oxide, mix and stir evenly, and then form the agent bar, and the forming catalyst is heated at 80°C Dry for 3 hours, then put it into an autoclave containing water at the bottom of the liner. The catalyst and liquid water are not in contact. After the autoclave is sealed, put it into the oven. After crystallization at 165°C for 80 hours, take it out, then wash it twice, and put it in the oven Dry at 120°C for 3 hours, place in a muffle furnace for calcination at 400°C for 2 hours, and 550°C for 3 hours to prepare a binder-free ZSM-5 / β zeolite catalyst as shown in Table 1. The XRD pattern of the prepared catalyst shows that ZSM-5 and β zeolite intergrowth phase. The sca...

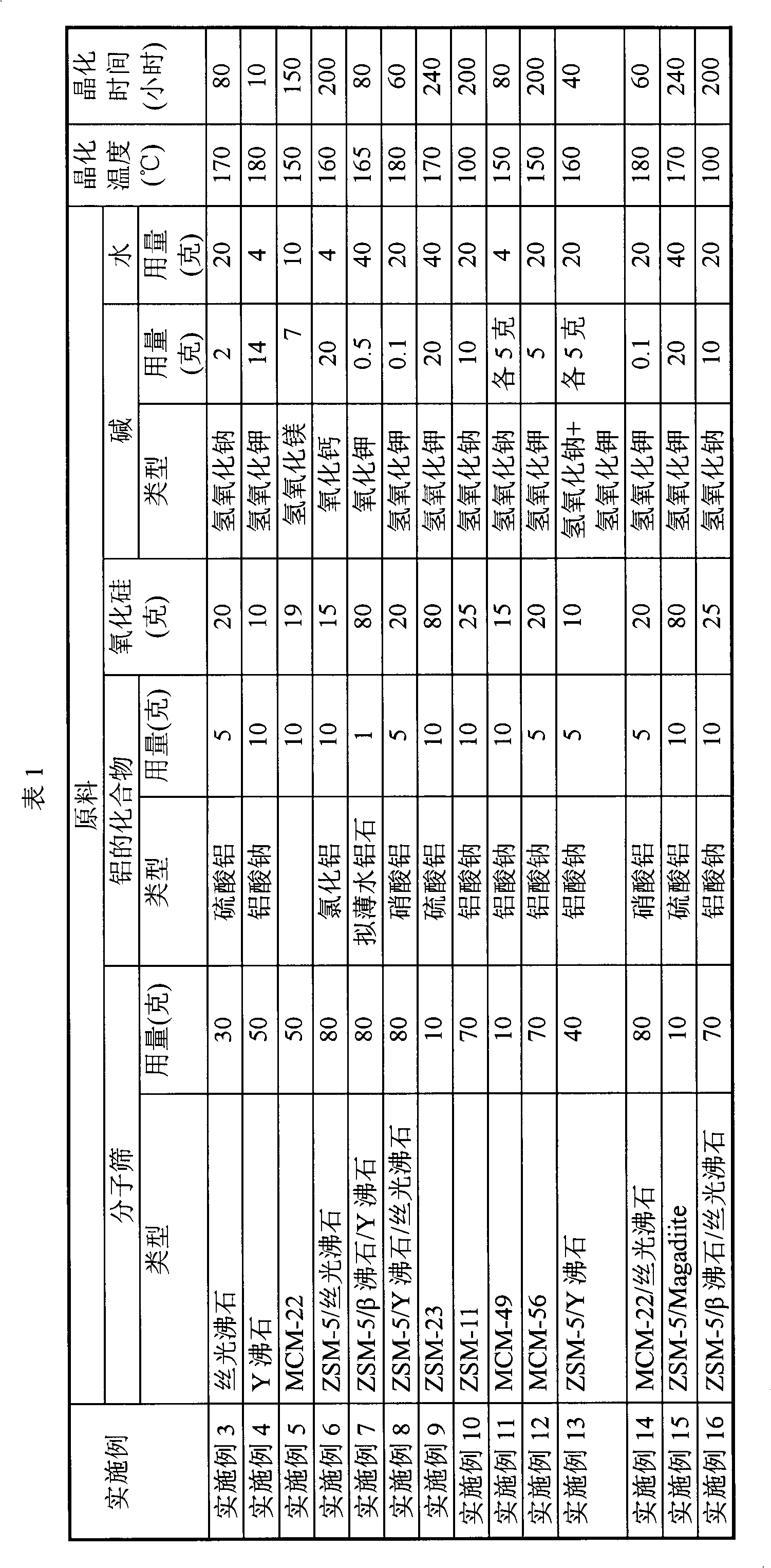

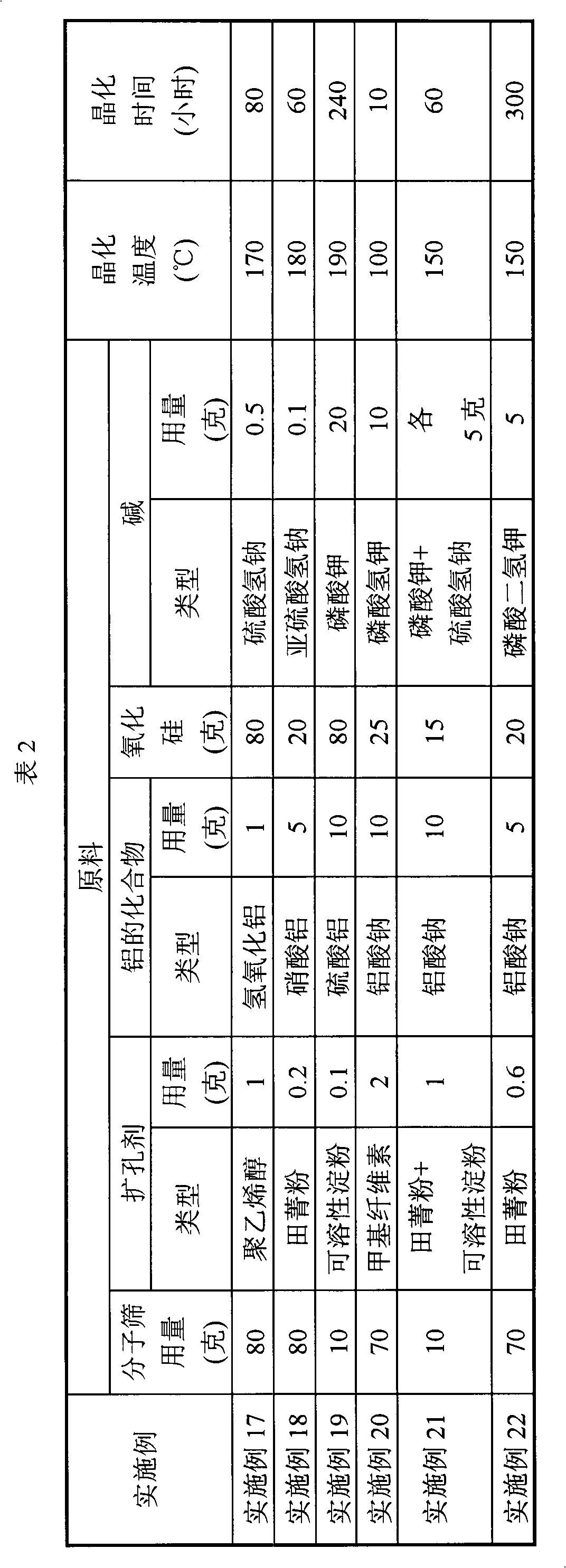

Embodiment 3~16

[0031] Take mordenite with a silicon-aluminum ratio of 20, 60 grams of Y zeolite with a silicon-aluminum ratio of 10, MCM-22 molecular sieve with a silicon-aluminum ratio of 40, ZSM-5 / mordenite symbiotic molecular sieve with a silicon-aluminum ratio of 20, and silicon-aluminum ratio ZSM-5 / beta zeolite / Y zeolite symbiotic molecular sieve with a ratio of 40, ZSM-5 / Y zeolite / mordenite symbiotic molecular sieve with a silicon-aluminum ratio of 20, ZSM-23 with a silicon-aluminum ratio of 20, and a silicon-aluminum ratio of 30 ZSM-11, MCM-49 with a silicon-aluminum ratio of 40, MCM-56 with a silicon-aluminum ratio of 60, ZSM-5 / Y symbiotic molecular sieves with a silicon-aluminum ratio of 20, MCM-22 / mordenite with a silicon-aluminum ratio of 40 , the ZSM-5 / Magadiite that the silicon-aluminum ratio is 200, the ZSM-5 / beta zeolite / mordenite that the silicon-aluminum ratio is 30, raw material proportioning is such as table 1, according to the method for embodiment 1, obtains binderless mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com