Method used for preparing tetrabutylammonium fluoride trihydrate

A technology of tetrabutylammonium fluoride and trihydrate, which is applied in the field of preparation of organic fluorine compounds, can solve the problems of complicated operation and high cost, and achieve the effects of convenient operation, short steps and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 80.57g (0.25mol) of tetrabutylammonium bromide, 21.79g (0.375mol) of potassium fluoride and 600mL of water into a 1L four-necked flask, and mechanically stir to dissolve. The solution was placed in a low-temperature bath at 1-10°C for crystallization, and a large amount of solids precipitated after half an hour. The crystallization was continued for one hour, and a large amount of white solid was obtained by suction filtration. Wash with a small amount of deionized water. Vacuum drying at 40°C for 24 hours gave a white solid.

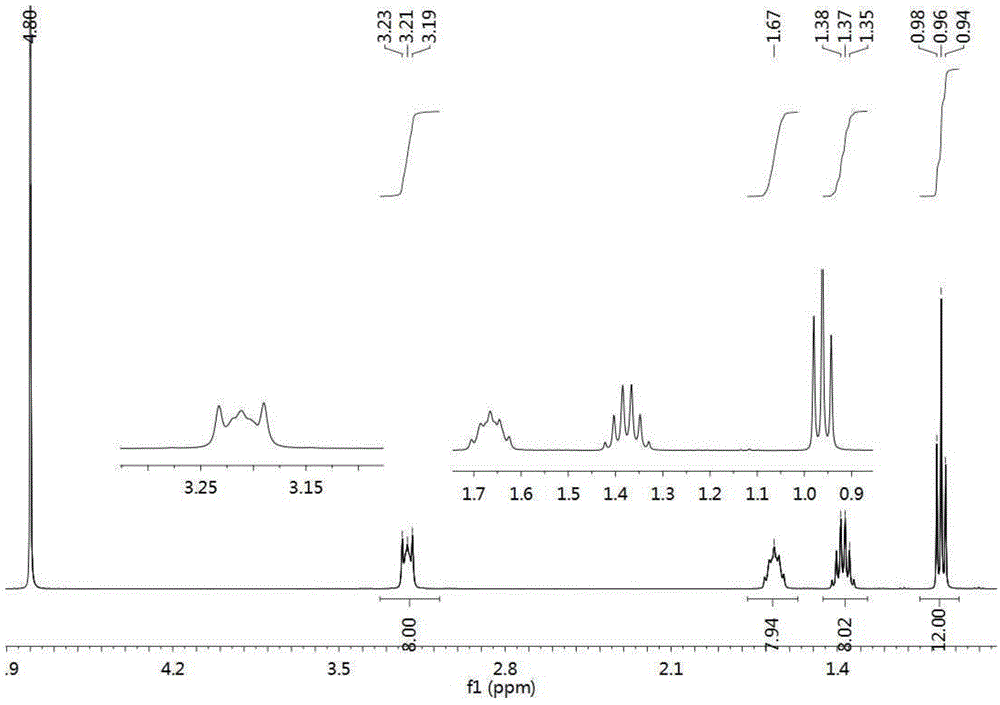

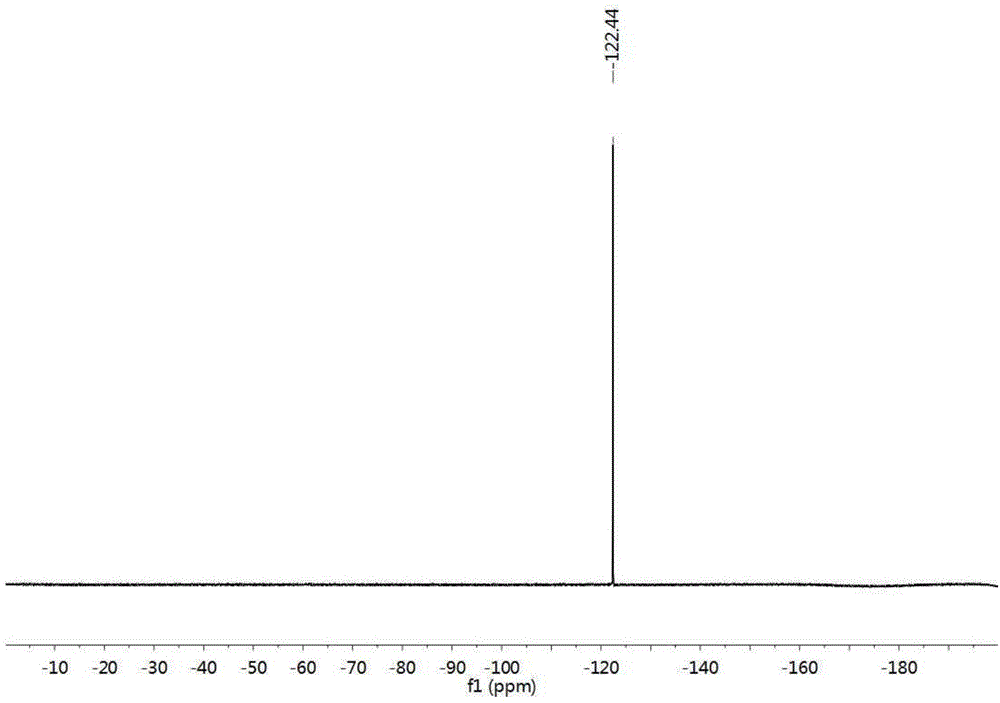

[0021] That 1 H-NMR spectrum see figure 1 , 19 F-NMR spectrum see figure 2 ,Data are as follows: 1 H NMR: (400MHz, D 2 O) 0.96(t, 12H), 1.38(m, 8H), 1.67(m, 8H), 3.21(m, 8H), 19 F NMR: (376MHz, D 2 (0) -122.44. After identification, its structural formula is N(CH 2 CH 2 CH 2 CH 3 ) 4 F·3H 2 O, namely tetrabutylammonium fluoride trihydrate. Yield 81.2%, moisture 17.25%.

Embodiment 2

[0023] Add 80.57g (0.25mol) of tetrabutylammonium bromide, 17.4g (0.30mol) of potassium fluoride and 600mL of water into a 1L four-necked flask, and mechanically stir to dissolve. The solution was placed in a low-temperature bath at 1-10°C for crystallization, and a large amount of solids precipitated after half an hour. The crystallization was continued for one hour, and a large amount of white solid was obtained by suction filtration. Wash with a small amount of deionized water. Vacuum drying at 40°C for 24 hours gave a white solid. Its nuclear magnetic data is identical with embodiment 1. Yield 75.5%, moisture 17.80%.

Embodiment 3

[0025] Add 80.57g (0.25mol) of tetrabutylammonium bromide, 145g (2.50mol) of potassium fluoride and 600mL of water into a 1L four-neck flask, and mechanically stir to dissolve. The solution was placed in a low-temperature bath at 1-10°C for crystallization, and a large amount of solids precipitated after half an hour. The crystallization was continued for one hour, and a large amount of white solid was obtained by suction filtration. Wash with a small amount of deionized water. Vacuum drying at 40°C for 24 hours gave a white solid. Its nuclear magnetic data is identical with embodiment 1. Yield 82.5%, moisture 18.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com