Method for preparing astraxantbin using phytoxanthin extraction

A technology of lutein and astaxanthin, applied to zeaxanthin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

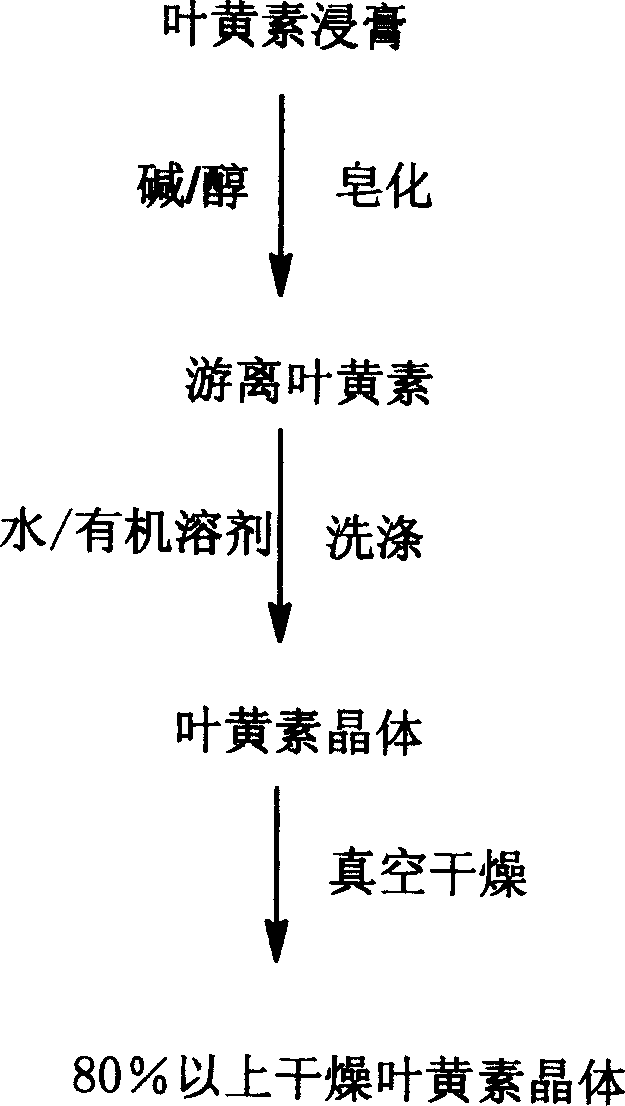

[0039] 1. Preparation of Lutein Crystals

[0040] Weigh 100 g of lutein extract (127 g lutein / kg extract) into a 250 ml three-neck flask, add 100 ml of ethanol, and stir in a constant temperature water bath at 56°C. After the internal and external temperatures were balanced, 20 g of 45% KOH aqueous solution was slowly added. Saponify for three hours. The saponification rate was detected by TLC > 95%.

[0041] After saponification is complete, add 600 ml of warm water at 35°C and stir. Adjust the pH value between 5-7 with 25% acetic acid, centrifugally filter, and discard the aqueous phase. Washed three times with water, the color of the filtrate was clear. Centrifuge to obtain lutein filter cake.

[0042] The filter cake was washed with 200 ml of n-hexane to remove sterols and fatty acids. Centrifuge to remove the n-hexane phase. The filter cake was vacuum dried. Lutein content reaches more than 80%.

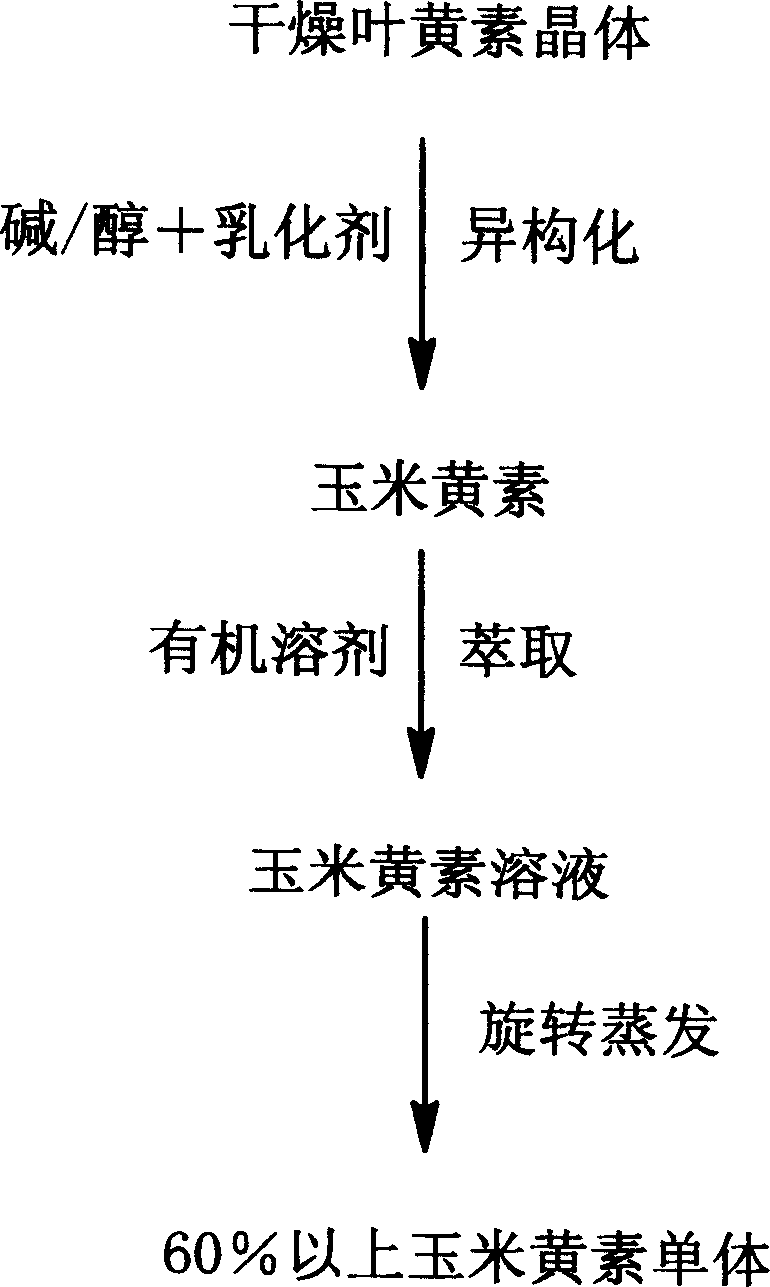

[0043] Then wash the lutein crystals with a nonpolar or weakly pol...

Embodiment 2

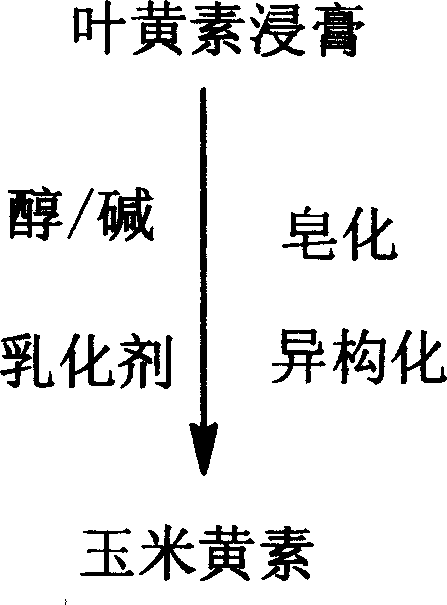

[0051] One-step production of zeaxanthin from lutein extract

[0052] Weigh 150g of dry lutein extract (130g lutein / kg extract) in an autoclave, add 150ml of propylene glycol and 20ml of nonylphenol polyoxyethylene ether, stir and mix evenly; then add 50g of KOH into the autoclave, And the reaction kettle was sealed well, and nitrogen protection was carried out. Slowly raise the temperature to 100°C, and react at a constant temperature for 20h. Maintain uniform rotational stirring (120 RPM) during the reaction. Samples were taken and analyzed by high-pressure liquid chromatography, and the conversion rate reached more than 80%. Weigh 1.4g of 60% zeaxanthin into a 50ml glass reactor, add 20ml of chloroform, and stir evenly. Aqueous sodium chlorate solution (0.3 g / 10 ml water) was added under ice cooling. NaHCO 3 The pH value of the solution was adjusted to make pH=8. Nitrogen protection was carried out subsequently, and the reaction was carried out for half an hour.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com