Preparation method for N-arylazoles compounds

A technology of azole compounds and compounds, applied in the field of compound preparation, can solve the problems of only 69% yield, low yield, and narrow scope of substrate application, and achieve the effects of low price, simple operation, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

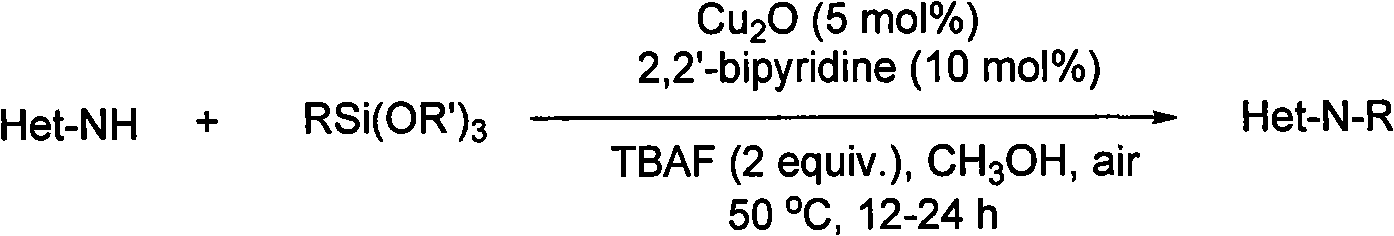

Method used

Image

Examples

Embodiment 1

[0019] Cu was added sequentially to a 25mL single-neck round bottom flask 2 O (4 mg, 5 mol%), 2,2'-bipyridine (8 mg, 10 mol%), methanol (3 mL), TBAF (1.0 mmol) in THF (1 M, 1 mL), phenyltrimethoxysilane (1 mmol) and Benzimidazole (0.5mmol), connected to a condensing reflux tube at the bottle mouth, placed the device in a 50°C oil bath, stirred magnetically, reacted for 12h, removed the solvent under reduced pressure, and carried out column separation with petroleum ether / ethyl acetate to obtain the product , NMR to determine the structure. Yield was 99%.

[0020] 1 H NMR (400MHz, CDCl 3 , TMS)δ8.04(s, 1H), 7.86-7.88(d, 1H, J=7.2Hz), 7.44-7.49(m, 3H), 7.35-7.39(m, 3H), 7.23-7.31(m, 2H). MS (EI): m / z (%): 194(100) [M + ], 193(24)[M + -1].

Embodiment 2

[0022] Cu was added sequentially to a 25mL single-neck round bottom flask 2 O (4 mg, 5 mol%), 2,2'-bipyridine (8 mg, 10 mol%), methanol (4 mL), TBAF (1.0 mmol) in THF (1 M, 1 mL), phenyltrimethoxysilane (1 mmol) and 5,6-Dimethylbenzimidazole (0.5mmol), connect the condensing reflux tube to the bottle mouth, place the device in a 50°C oil bath, stir magnetically, react for 24h, remove the solvent under reduced pressure, use petroleum ether / ethyl acetate The ester was subjected to column separation to obtain the product, and the structure was determined by NMR. Yield was 89%.

[0023] 1 H NMR (400MHz, CDCl 3 , TMS)δ8.00(s, 1H), 7.63(s, 1H), 7.53-7.57(t, 2H), 7.41-7.49(m, 3H), 7.31(s, 1H), 2.39(s, 3H) , 2.37 (s, 3H). MS (EI): m / z (%): 222 (100) [M + ], 221(51)[M + -1], 207(55), 77(7).

Embodiment 3

[0025] Cu was added sequentially to a 25mL single-neck round bottom flask 2 O (7 mg, 5 mol%), 2,2'-bipyridine (16 mg, 10 mol%), methanol (6 mL), TBAF (2.0 mmol) in THF (1 M, 2 mL), phenyltrimethoxysilane (2 mmol) and Imidazole (1.0 mmol), connected to a condensing reflux tube at the bottle mouth, placed the device in a 50°C oil bath, stirred magnetically, reacted for 12 h, removed the solvent under reduced pressure, and carried out column separation with petroleum ether / ethyl acetate to obtain the product. NMR Determine the structure. Yield was 98%.

[0026] 1 H NMR (400MHz, CDCl 3 , TMS)δ7.86(s, 1H), 7.46-7.49(t, 2H), 7.36-7.39(t, 3H), 7.27(s, 1H), 7.21(s, 1H). MS(EI): m / z(%): 144(100)[M + ], 117(43), 90(31), 77(23), 51(10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com