Preparation method of graphdiyne film and graphdiyne film

A technology of graphyne and film, which is applied in the field of graphyne, can solve the problems of restricting mass production, application field restrictions, and low yield of graphyne, and achieves the effects of easy industrial production, improving utilization rate, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

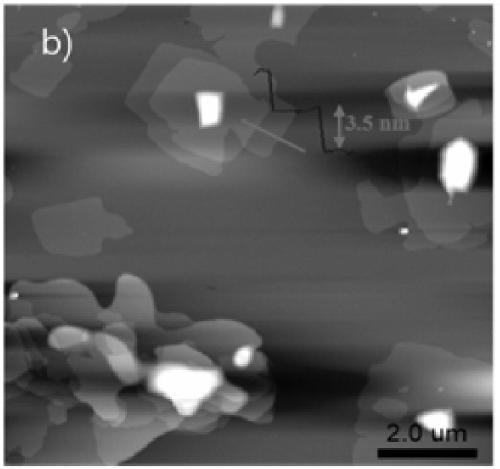

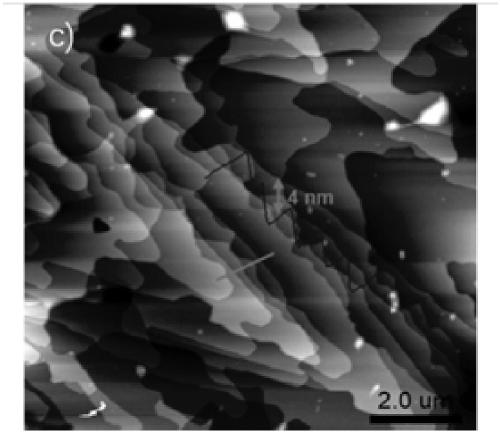

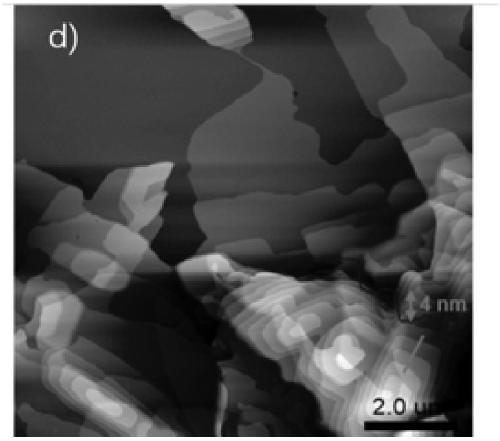

Image

Examples

preparation example Construction

[0033] In view of this, in one aspect of the present invention, the present invention proposes a preparation method of a graphdiyne film. According to an embodiment of the present invention, the method includes: (1) mixing a catalyst with water to obtain a catalyst solution; (2) mixing a monomer with an organic solvent to obtain a monomer solution, and adding four Butyl ammonium fluoride, obtain hexa-alkynyl benzene solution; (3) mix described hexa-alkynyl benzene solution, described catalyst solution and water, mix under the effect of inert gas atmosphere and stirring to obtain mixed solution; (4 ) reacting the mixed solution, and separating the graphyne film from the reaction product; wherein, the monomer is a compound shown in formula (I),

[0034]

[0035] According to the method for preparing a graphyne film according to an embodiment of the present invention, first, a catalyst solution and a hexaynylbenzene solution are prepared respectively, wherein the catalyst solu...

Embodiment 1

[0062] (1) Dissolve 0.25 mg of copper acetate and 2.5 mL of pyridine in 2.5 mL of distilled water to form a catalyst solution, and blow nitrogen into the catalyst solution to remove oxygen;

[0063] (2) Dissolve 3.6 mg of monomer in 1 mL of dichloromethane to prepare a monomer solution with a concentration of 3.6 mg / mL, blow nitrogen into the monomer solution to remove oxygen; then add 36 μL TBAF solution (1mol / L tetrahydrofuran solution ), shaking reaction 1min, obtains the hexa-alkynylbenzene solution;

[0064] (3) Mix 1mL of hexaynylbenzene solution, 0.3mL of catalyst solution, and 8.7mL of distilled water. The ratio of the volume of hexaynylbenzene solution to the volume of catalyst solution and distilled water is 1:9. Under the protection of inert gas and stirring Mix it evenly to obtain a mixed solution;

[0065] (4) After the mixed solution was reacted for 3 days, the liquid was removed, and the product was cleaned, and the obtained solid was graphyne, and the yield of...

Embodiment 2

[0067] (1) Dissolve 0.25 mg of copper acetate and 2.5 mL of pyridine in 2.5 mL of distilled water to form a catalyst solution, and blow nitrogen into the catalyst solution to remove oxygen;

[0068] (2) Dissolve 3.6 mg of monomer in 1 mL of chloroform to prepare a monomer solution with a concentration of 3.6 mg / mL, blow nitrogen into the monomer solution to remove oxygen; then add 36 μL of TBAF solution (1mol / L tetrahydrofuran solution), shaking and reacting for 1min to obtain a hexaacetylenylbenzene solution;

[0069] (3) Mix 1mL of hexaynylbenzene solution, 0.3mL of catalyst solution, and 8.7mL of distilled water. The ratio of the volume of hexaynylbenzene solution to the volume of catalyst solution and distilled water is 1:9. Under the protection of inert gas and stirring Mix it evenly to obtain a mixed solution;

[0070] (4) After the mixed solution was reacted for 3 days, the liquid was removed, and the product was cleaned, and the obtained solid was graphyne, and the yi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com