Treatment system and treatment method for divinyl benzene production tail gas

A divinylbenzene and treatment system technology, which is applied in the direction of gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of no process technology and few patents related to divinylbenzene tail gas treatment, and achieve the amount of absorbent Reasonable, mild operating temperature and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

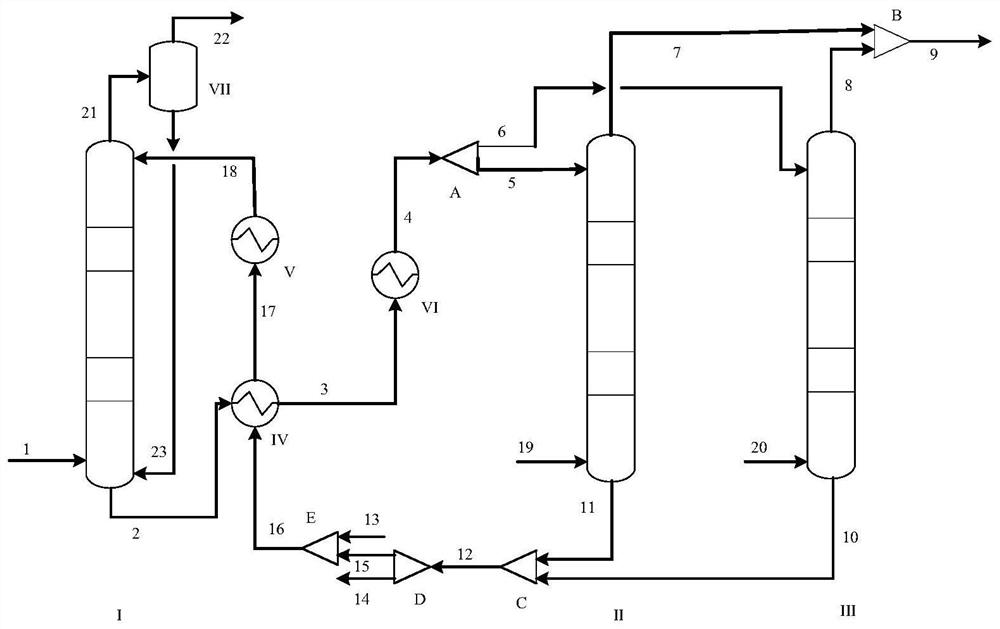

[0071] as Figure 1 As shown, the exhaust gas treatment system for the production of divinylbenzene in Example 1 comprises: a tail gas absorption tower, a first desorption tower, a second desorption tower, a flash tank, a heat exchanger, a heater, a incoming material distributor, a first mixer, an exhaustor, a second mixer, a cooler and a third mixer, wherein the exhaust gas absorption tower I is provided with a tower bottom inlet, for receiving absorbers and fresh absorbers from the desorption tower, the tower bottom outlet and the tower top outlet; the first desorption tower and the second desorption tower are respectively provided with a tower top inlet, Tower bottom inlet, tower top outlet and tower bottom outlet; flash tank is provided with inlet, tower top outlet and tower bottom outlet; cooler and heater are respectively provided with inlet and outlet; heat exchanger is provided with cold material inlet and cold material outlet, hot material inlet and hot material outlet.

[0...

Embodiment 2

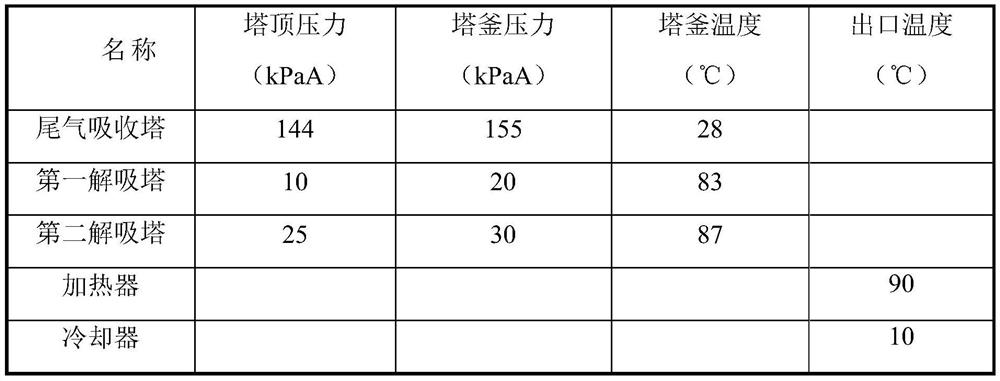

[0085] Example 2 adopts the treatment system and treatment method in Example 1, the difference is only in the exhaust gas absorption tower, the first desorption tower, the second desorption tower, the heater and the cooler using the operating conditions in Table 3, the amount of absorbent is 7.2 times the feed mass. The feed composition and separation effect are shown in Table 4.

[0086] Table 3

[0087]

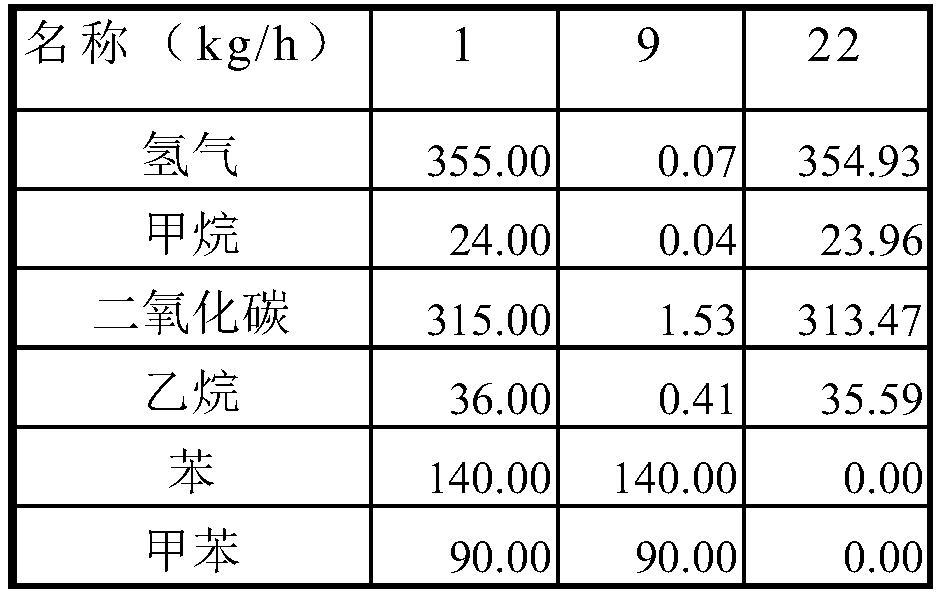

[0088] Table 4

[0089]

[0090]

[0091] According to the calculations in Table 4, the recovery rate of benzene, toluene, diethylbenzene and divinylbenzene was 98.92%.

Embodiment 3

[0093] Example 3 is substantially the same as Example 2, the outlet temperature of the cooler is 30 ° C. The feed composition and separation effect of Example 3 is shown in Table 5.

[0094] Table 5

[0095]

[0096]According to the calculations in Table 5, the recovery rate of benzene, toluene, diethylbenzene and divinylbenzene is 98.64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com