Spent lithium-ion battery electrolyte supercritical carbon dioxide extraction process and device

A lithium-ion battery and carbon dioxide technology, applied in solvent extraction, battery recycling, solid solvent extraction, etc., can solve problems such as poor production safety, frequent lifting of materials, and reduced production efficiency, and achieve mild operating temperature and pressure conditions, avoiding human body Poisoning and environmental pollution, the effect of reducing the height of the plant space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

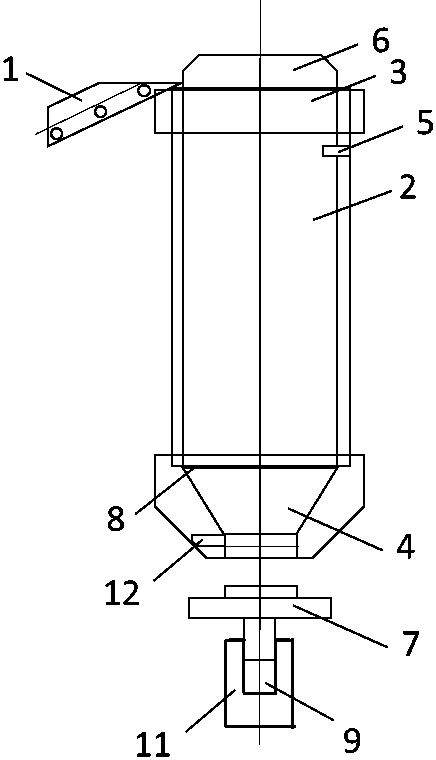

[0033] 1. Close the discharge port at the bottom of the extraction kettle, open the head 6 of the top 3 of the kettle body, start the fully sealed conveyor belt 1, crush the waste lithium-ion batteries containing the electrolyte, put them into the extraction kettle, and close the kettle The upper seal 6 on the top 3 of the body closes the charging opening on the top of the extraction kettle to complete the charging process. The waste lithium-ion battery scrap containing electrolyte is lithium cobalt oxide battery.

[0034] 2. Close the carbon dioxide outlet at the top, open the carbon dioxide inlet at the bottom, press the carbon dioxide into the extraction kettle from the carbon dioxide inlet 12 at the bottom 4 of the kettle body with a booster pump, and then use the booster pump to pump the solubility enhancer ethanol ester from the bottom 4 of the kettle body The carbon dioxide inlet 12 of the extraction kettle is pressed into the extraction kettle, and the carbon dioxide p...

Embodiment 2

[0037] 1. Close the discharge port at the bottom of the extraction kettle, which will contain LiPF 6 / (DMC+EC+DEC+VC+BP) The waste NCM ternary lithium-ion battery fragments of the electrolyte are put into the extraction kettle, and the charging opening at the top of the extraction kettle is closed to complete the charging process.

[0038] 2. Close the carbon dioxide outlet at the top, open the carbon dioxide inlet at the bottom, and turn on the heating device of the extraction kettle to keep the temperature of the extraction kettle body above 40°C and keep it constant. Use a booster pump to press carbon dioxide and solubility enhancer propane into the extraction kettle. And make the carbon dioxide pressure in the extraction tank remain constant at 10MPa, start the supercritical carbon dioxide extraction of the electrolyte solution of the waste lithium-ion battery at this moment, the consumption of described solubility enhancer propane is 15% of the electrolyte consumption cont...

Embodiment 3

[0042] 1. Close the discharge port at the bottom of the extraction kettle, which will contain LiPF 6 / (DMC+EC+VC) The waste lithium iron phosphate battery fragments of the electrolyte are put into the extraction kettle, and the charging opening at the top of the extraction kettle is closed to complete the charging process.

[0043] 2. Close the carbon dioxide outlet at the top, open the carbon dioxide inlet at the bottom, turn on the heating device of the extraction kettle, keep the temperature of the extraction kettle at 50°C and keep it constant, and press the carbon dioxide and the solubility enhancer diethyl carbonate into the Extraction kettle, and make the carbon dioxide pressure in the extraction kettle keep at 17MPa and keep constant, start the supercritical carbon dioxide extraction of spent lithium-ion battery electrolyte at this moment. The amount of the solubility enhancer diethyl carbonate is 30% by weight of the amount of electrolyte contained in the waste lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com