Uvioresistant polyethylene non-woven fabric and preparation method thereof

A UV-resistant, polyethylene technology, applied in the direction of single-component polyolefin rayon, rayon manufacturing, textiles and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

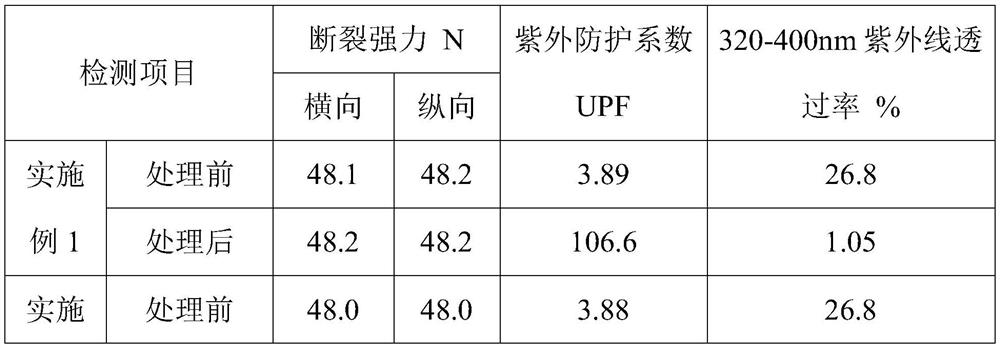

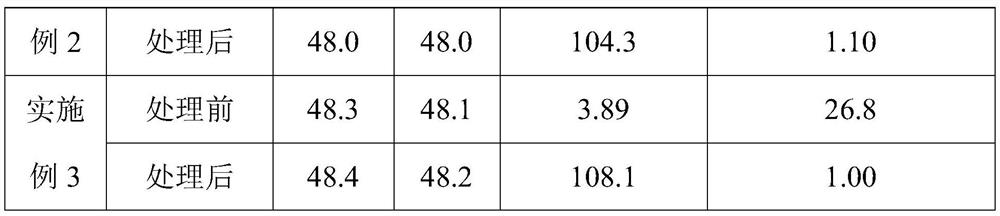

Embodiment 1

[0025] An anti-ultraviolet polyethylene non-woven fabric, a polydopamine layer and a titanium dioxide layer are sequentially adhered to the surface of the polyethylene non-woven fabric; the titanium dioxide is γ-aminopropyltriethoxysilane modified titanium dioxide; the polyethylene The raw material of the non-woven fabric contains 8wt% titanium dioxide and 15wt% carbon black.

[0026] The preparation method of above-mentioned anti-ultraviolet polyethylene non-woven fabric, comprises the steps:

[0027] S1. Ultrasonic cleaning of polyethylene non-woven fabrics (10cm×10cm, mass per unit area 45g / m2) with ethanol 2 ), then rinsed with water, and dried at 35°C for later use;

[0028] Add the washed and dried polyethylene non-woven fabric to 500ml of dopamine solution with a concentration of 3mg / ml, soak it at room temperature for 48 hours, then take it out, rinse it with water, and dry it at 35°C to obtain the intermediate fabric. Among them, the solvent of dopamine solution It ...

Embodiment 2

[0031] An anti-ultraviolet polyethylene nonwoven fabric, a polydopamine layer and a titanium dioxide layer are sequentially adhered to the surface of the polyethylene nonwoven fabric; the titanium dioxide is 3-mercaptopropyltriethoxysilane modified titanium dioxide; the polyethylene The raw material of the nonwoven fabric contains 10 wt% titanium dioxide and 10 wt% carbon black.

[0032] The preparation method of above-mentioned anti-ultraviolet polyethylene non-woven fabric, comprises the steps:

[0033] S1. Ultrasonic cleaning of polyethylene non-woven fabrics (10cm×10cm, mass per unit area 45g / m2) with ethanol 2 ), then rinsed with water, and dried at 35°C for later use;

[0034] Add the washed and dried polyethylene non-woven fabric to 500ml of dopamine solution with a concentration of 3.5mg / ml, soak it at room temperature for 36 hours, take it out, rinse it with water, and dry it at 35°C to obtain the middle fabric. The solvent is a Tris-HCl buffer solution with a pH of...

Embodiment 3

[0037] An anti-ultraviolet polyethylene non-woven fabric, a polydopamine layer and a titanium dioxide layer are sequentially adhered to the surface of the polyethylene non-woven fabric; the titanium dioxide is γ-aminopropyltriethoxysilane modified titanium dioxide; the polyethylene The raw materials of the nonwoven fabric contained 9 wt% titanium dioxide and 12 wt% carbon black.

[0038] The preparation method of above-mentioned anti-ultraviolet polyethylene non-woven fabric, comprises the steps:

[0039] S1. Ultrasonic cleaning of polyethylene non-woven fabrics (10cm×10cm, mass per unit area 45g / m2) with ethanol 2 ), then rinsed with water, and dried at 35°C for later use;

[0040] Add the washed and dried polyethylene non-woven fabric to 500ml of dopamine solution with a concentration of 3.2mg / ml, soak it at room temperature for 42 hours, take it out, rinse it with water, and dry it at 35°C to obtain the middle fabric. Among them, the content of dopamine solution The solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com