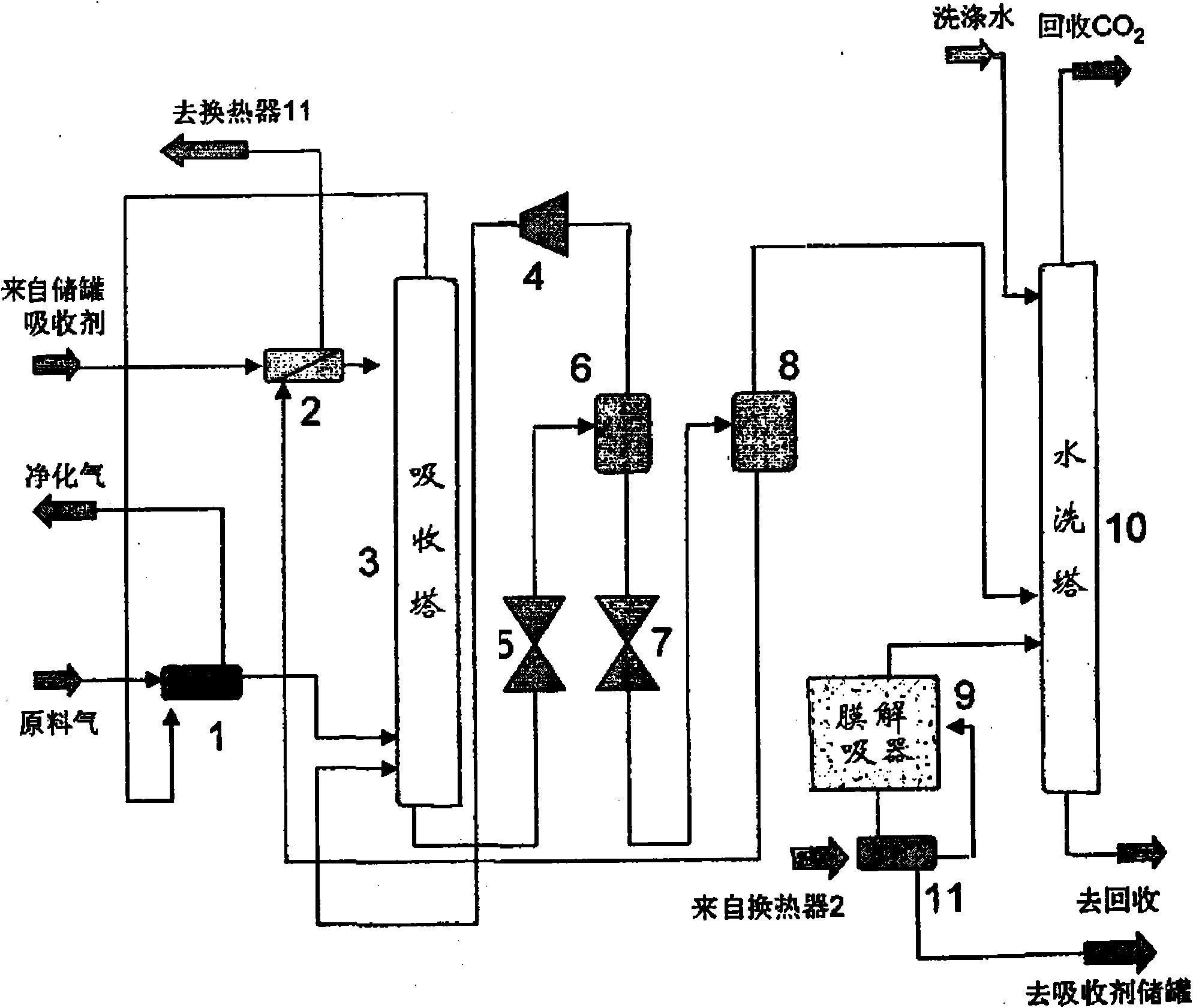

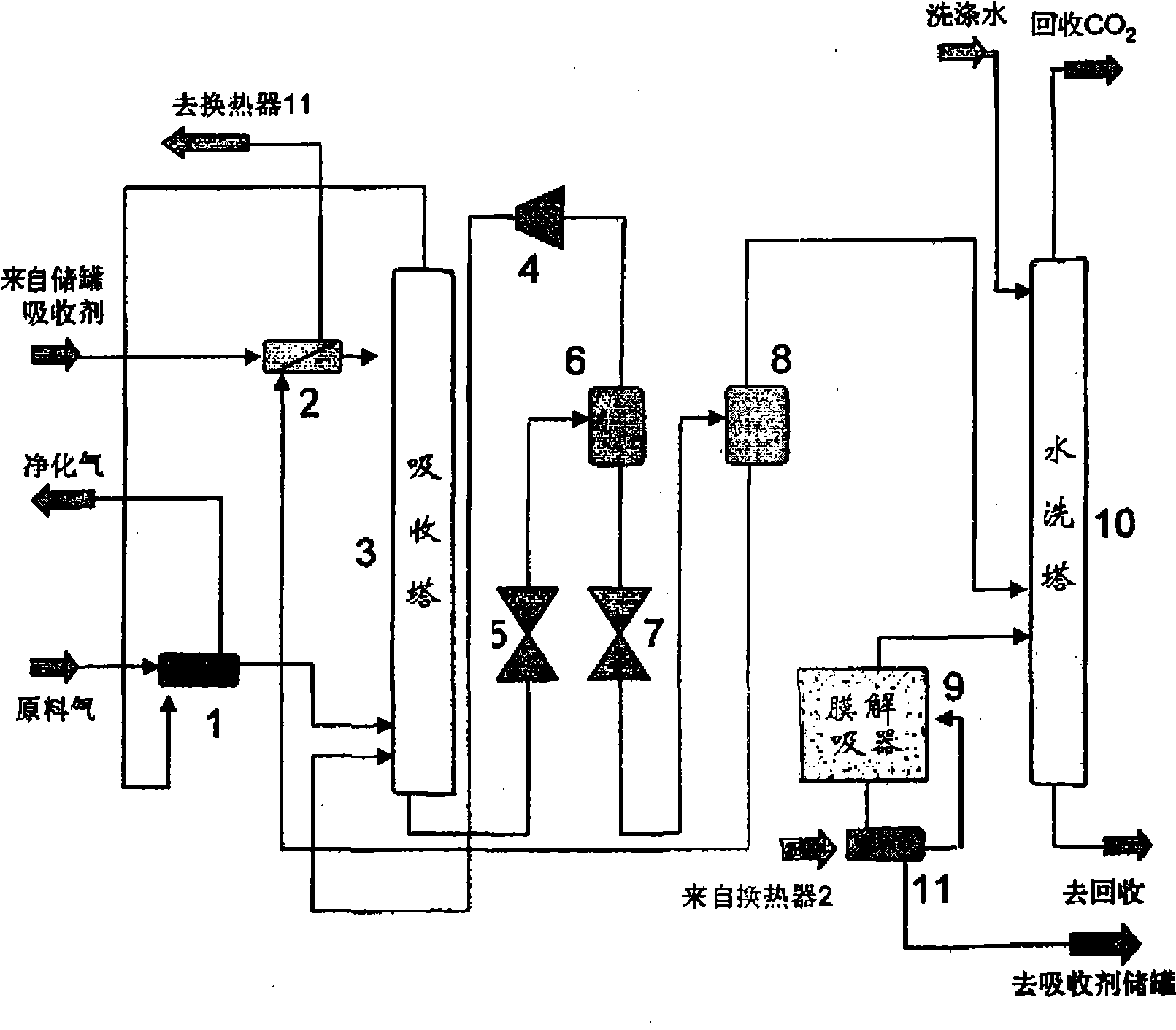

CO2 trapping method combining dimethyl carbonate absorption and membrane desorption

A technology of dimethyl carbonate and CO2, applied in the field of chemical engineering, can solve the problems of increased equipment investment, large equipment investment, long process flow, etc., and achieves the effects of reducing equipment investment, reducing energy consumption, and low solvent prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Contains CO 2 The mixed gas composition (mol fraction) is as follows:

[0035]CO 2 is 0.4210; H 2 is 0.5235; DMCARB is 0; CO is 0.0141;

[0036] Ar is 6.8000E-03; METHANE is 8.7000E-03; N 2 is 0.0254;

[0037] h 2 S is 4.60000E-04; H 2 O is 0,

[0038] The temperature of the mixed gas is 28°C and the pressure is 2.6MPa;

[0039] Mixed gas and absorption tower top to remove CO 2 After heat exchange, the purified gas drops to 23.2°C and enters the absorption tower from the lower part. The dimethyl carbonate from the absorbent storage tank at 25°C exchanges heat with the liquid phase of the secondary desorption tank and enters the absorption tower from the upper part after reaching 14.3°C. Two-phase Countercurrent contact and absorption mass transfer occur in the column. The gas phase flow rate is 22121KG-MOL / HR, and the liquid phase flow rate is 54323KG-MOL / HR. The temperature at the top of the absorption tower is 15.5°C and the pressure is 2.55MPa; the tempera...

Embodiment 2

[0048] Contains CO 2 The mixed gas has a temperature of 27°C and a pressure of 2.9MPa. The composition (mol fraction) is as follows:

[0049] CO 2 : 0.4210; H 2 :0.5235:DMCARB:0;CO:0.0141;

[0050] Ar: 6.8000E-03; METHANE: 8.7000E-03: N 2 : 0.0254;

[0051] h 2 S: 4.60000E-04; H 2 O: 0;

[0052] Mixed gas and absorption tower top to remove CO 2 After heat exchange, the purified gas drops to 23.1°C and enters the absorption tower from the lower part. The dimethyl carbonate from the absorbent storage tank at 25°C exchanges heat with the liquid phase of the secondary desorption tank and enters the absorption tower from the upper part after reaching 15.1°C. Two-phase Countercurrent contact and absorption mass transfer occur in the column. The gas phase flow rate is 22117KG-MOL / HR, and the liquid phase flow rate is 58611KG-MOL / HR. The temperature at the top of the absorption tower is 15.8°C and the pressure is 2980KPa; the temperature at the bottom of the tower is 29.2°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com