Patents

Literature

38results about How to "Increase heat and mass transfer rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

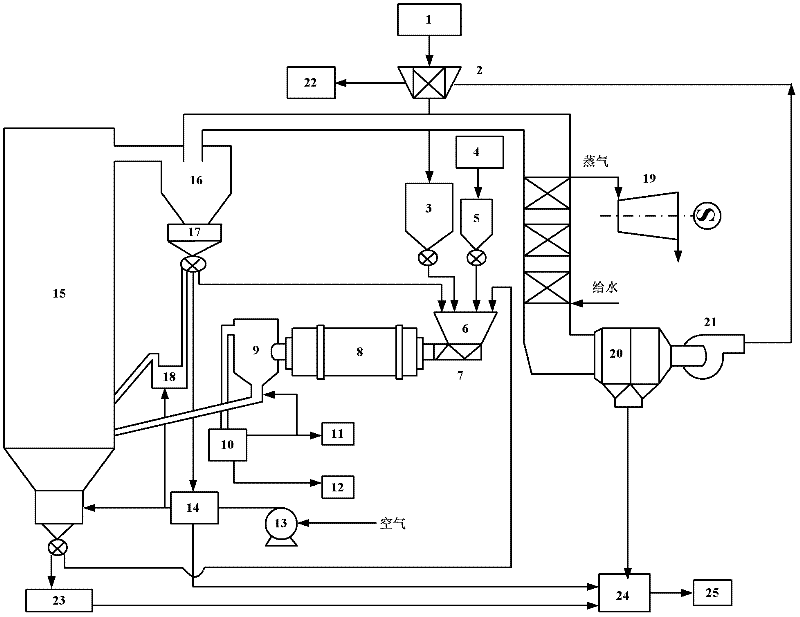

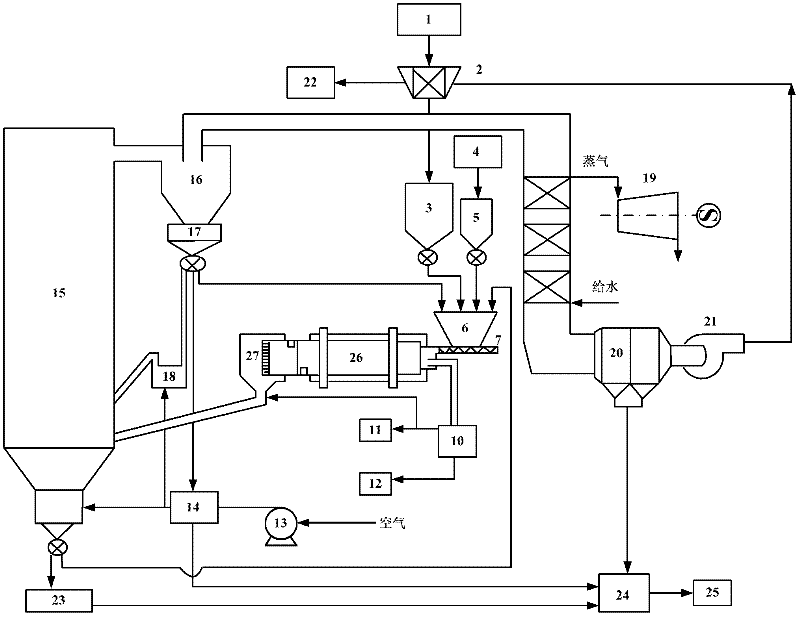

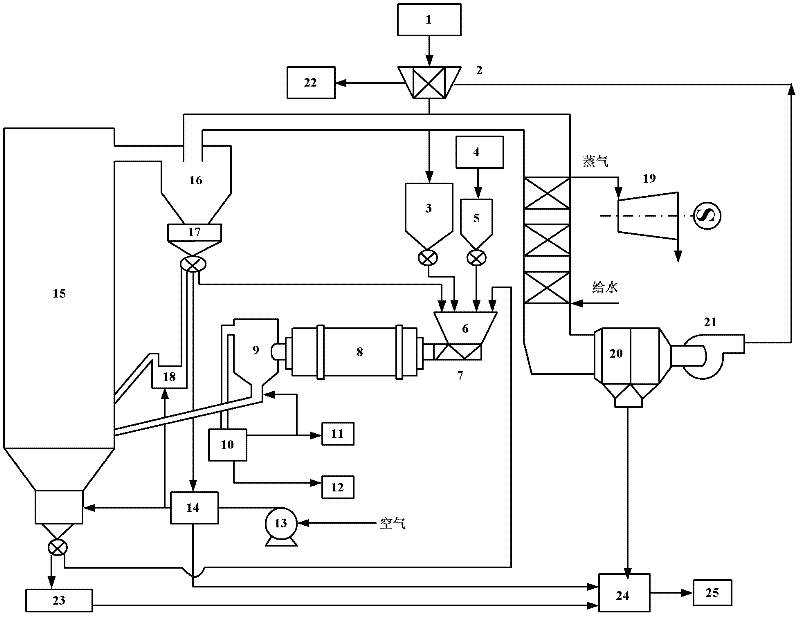

Oil shale rotary kiln dry distillation and circulating fluidized bed combustion process

InactiveCN102533296AImprove combustion efficiencyControl generationDirect heating destructive distillationBiofuelsBottom ashInternal combustion engine

An oil shale rotary kiln dry distillation and circulating fluidized bed combustion process makes organic combination of a rotary kiln dry distillation with a circulating fluidized bed; oil shale particles are mixed with thermal-cycle ash from a circulating fluidized bed boiler and part of circulating fluidized bed boiler bottom ash, and then are sent into a rotary kiln for dry distillation to prepare shale oil and dry distillation coal gas; the dry distillation coal gas has a high calorific value; a part of the coal gas is used as recycle wind of a semicoke material recycle device, and enters the circulating fluidized bed boiler with oil shale semicoke particles for combustion, and the residual part is delivered into an internal combustion engine for combustion generation. The invention can increase shale oil and coal gas quality, reduce energy loss and environment pollution, and improve the comprehensive utilization degree.

Owner:SHANGHAI JIAO TONG UNIV

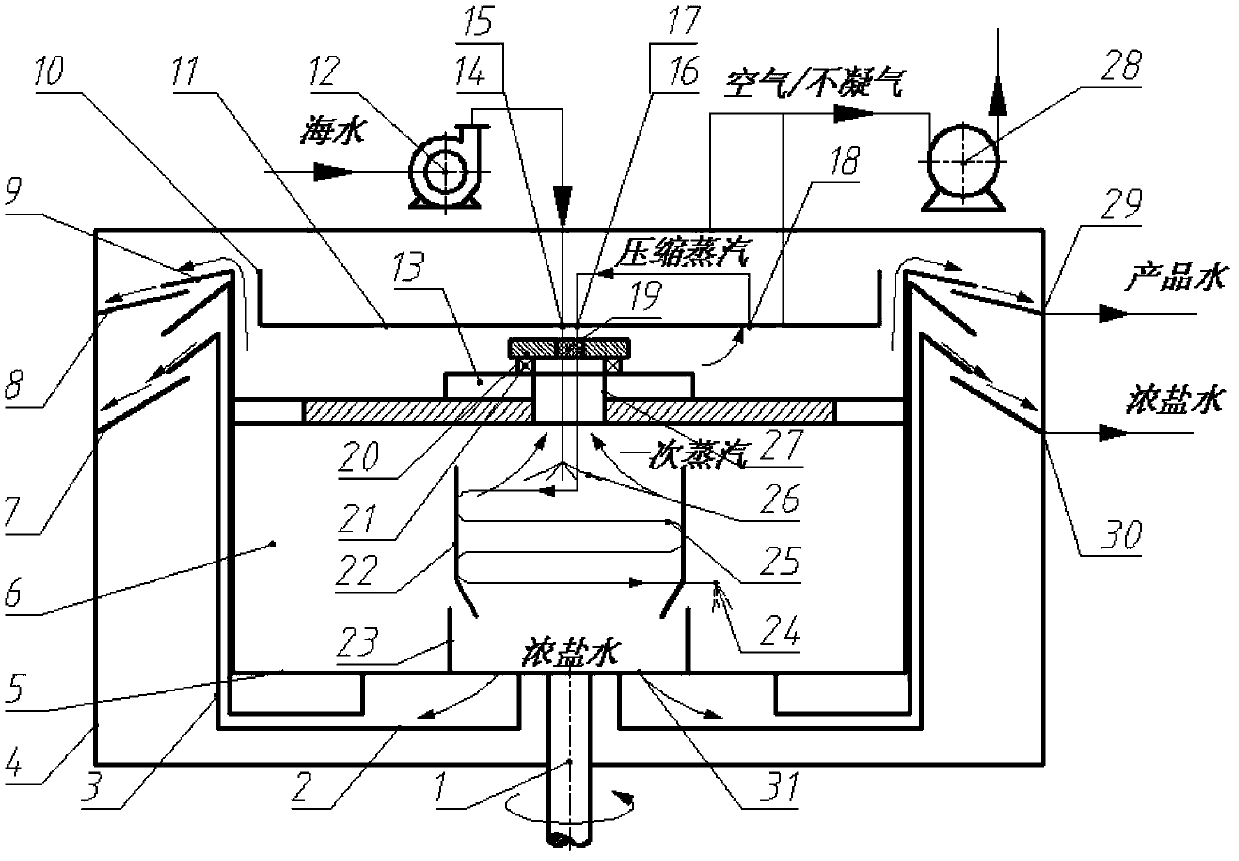

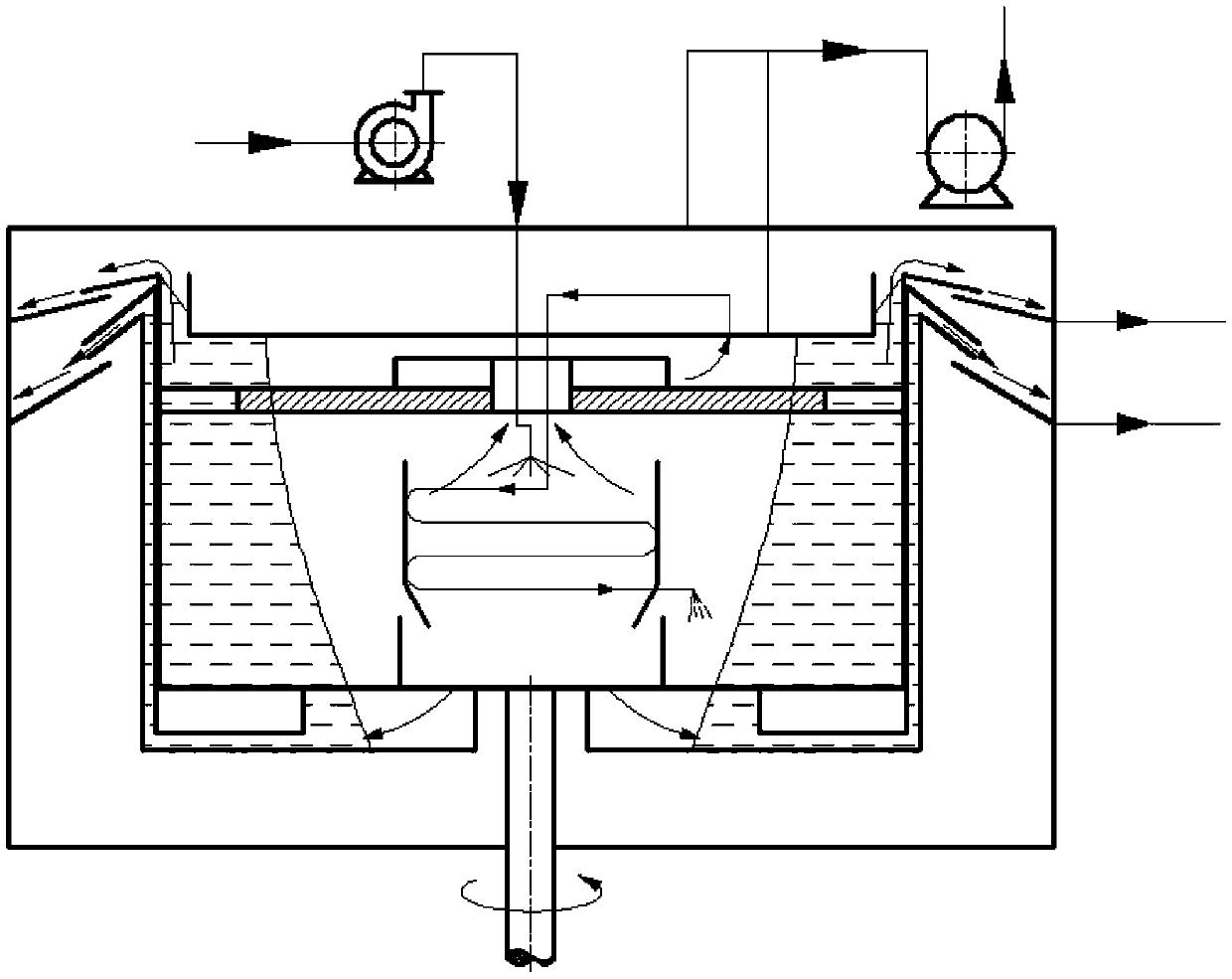

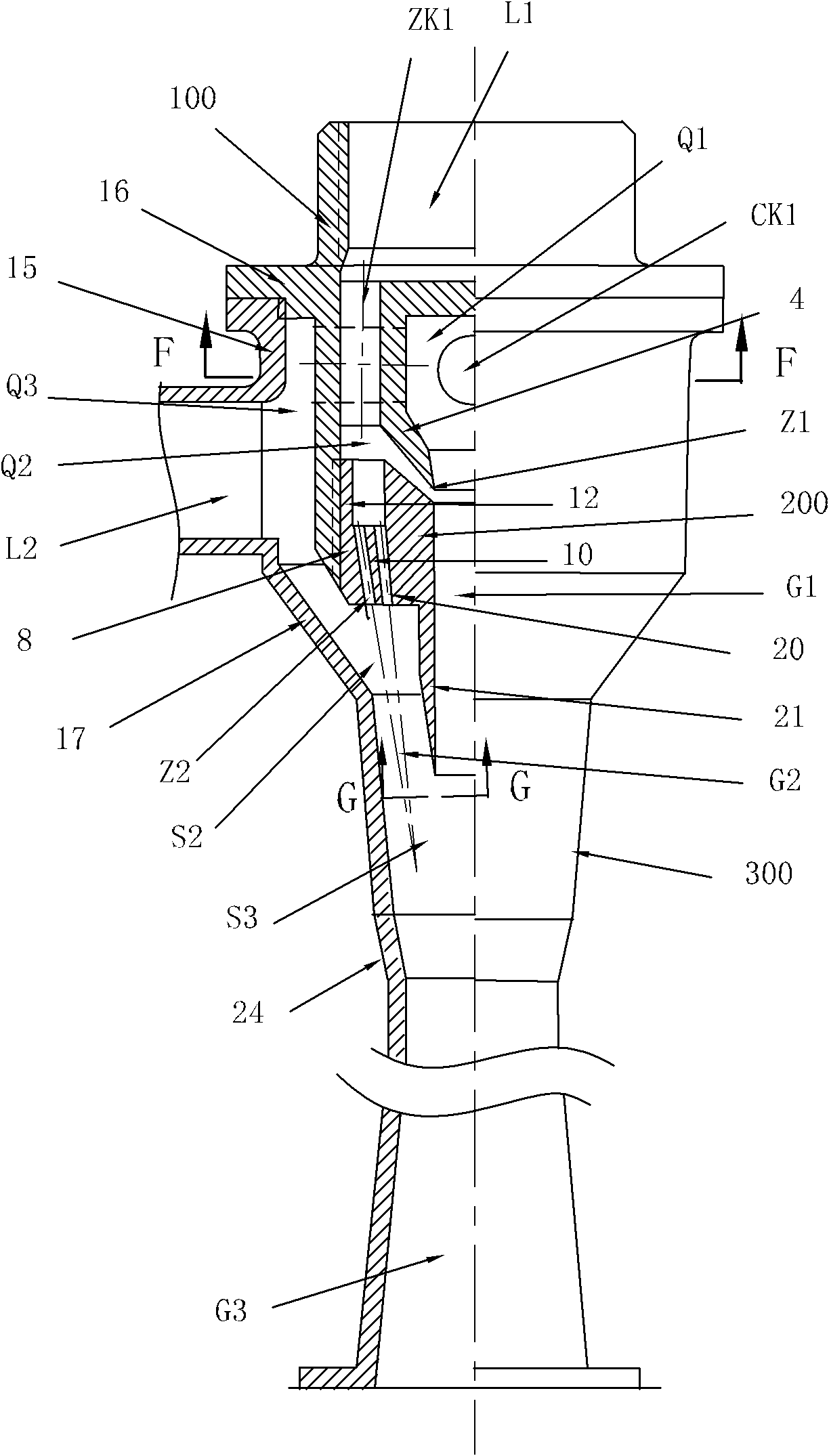

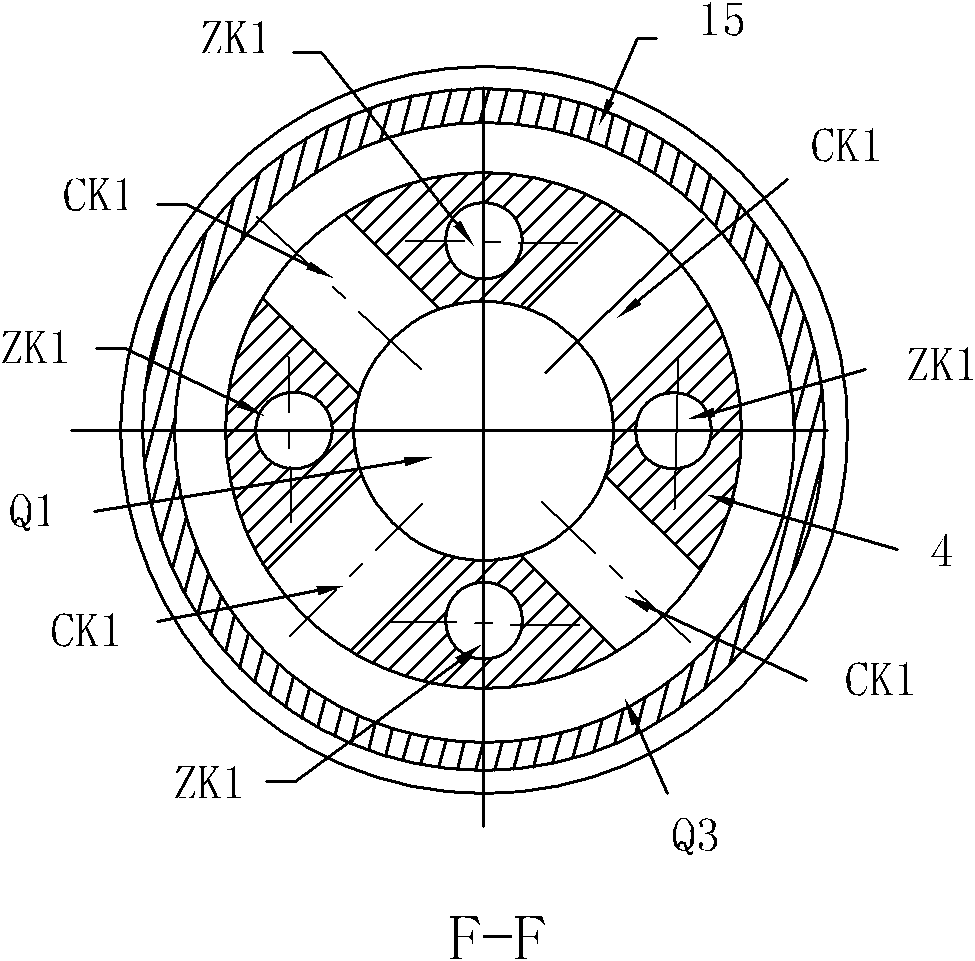

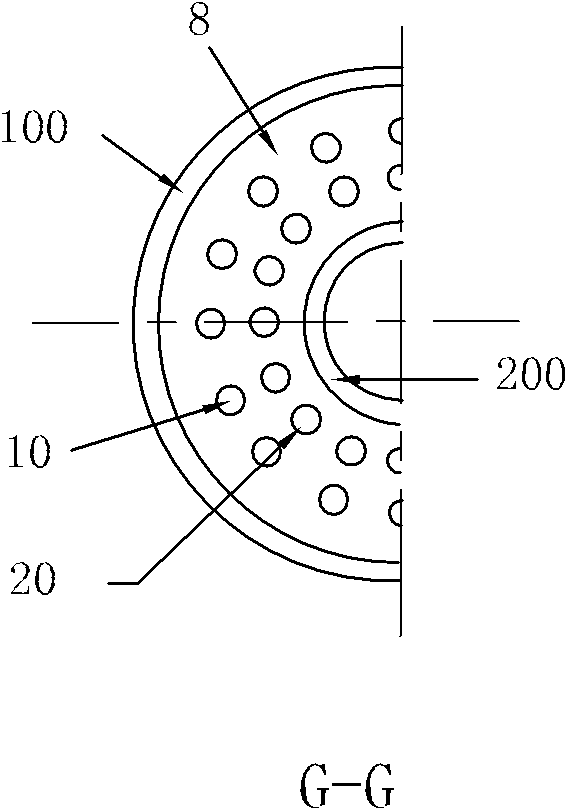

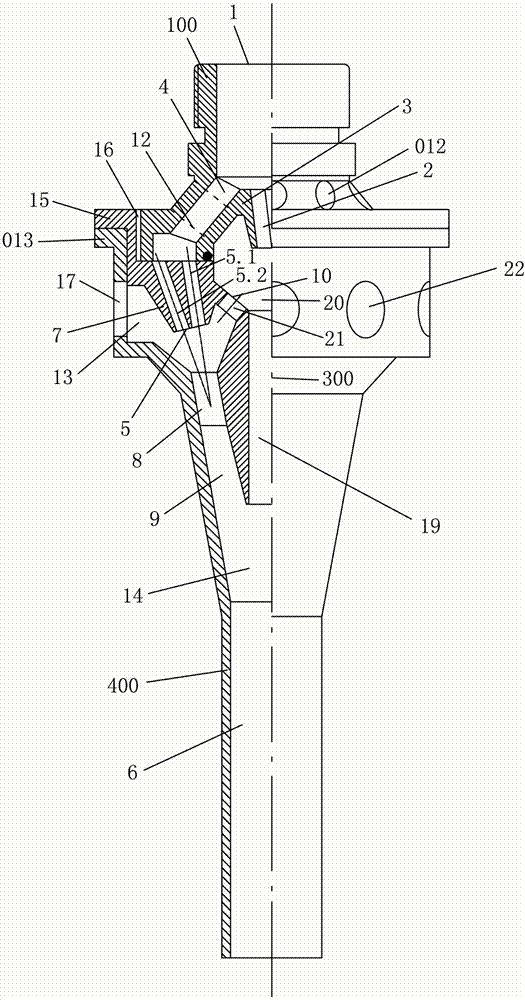

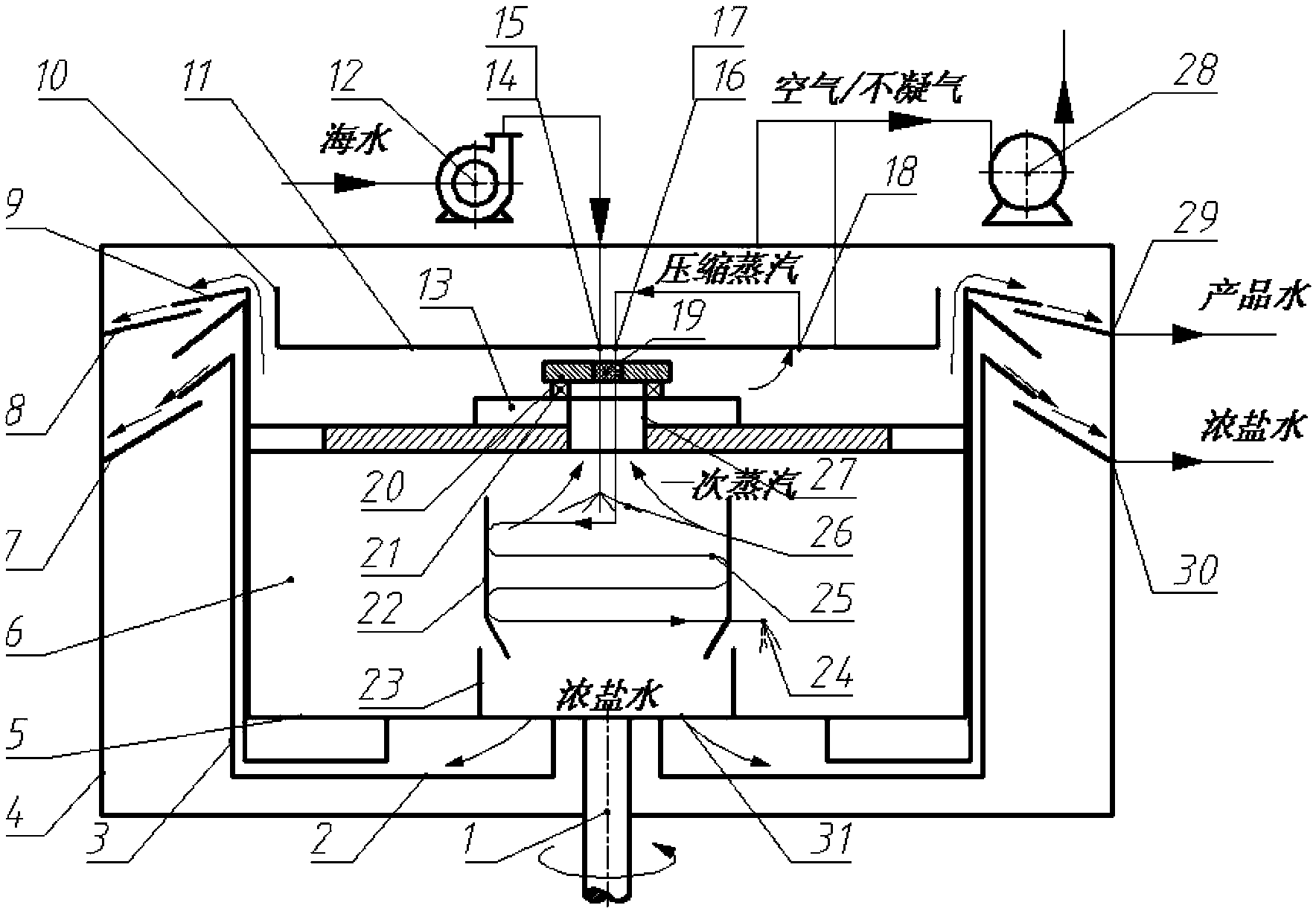

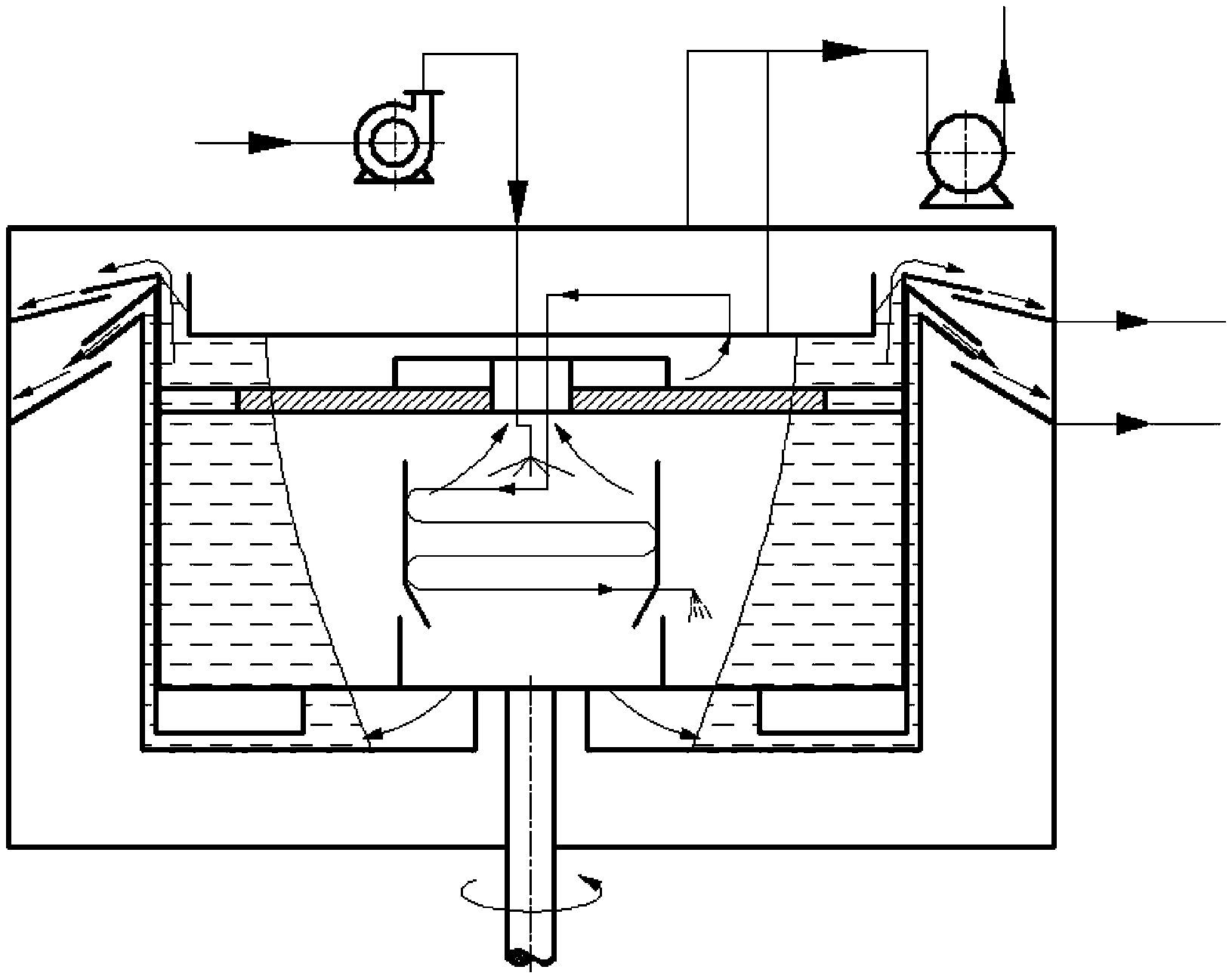

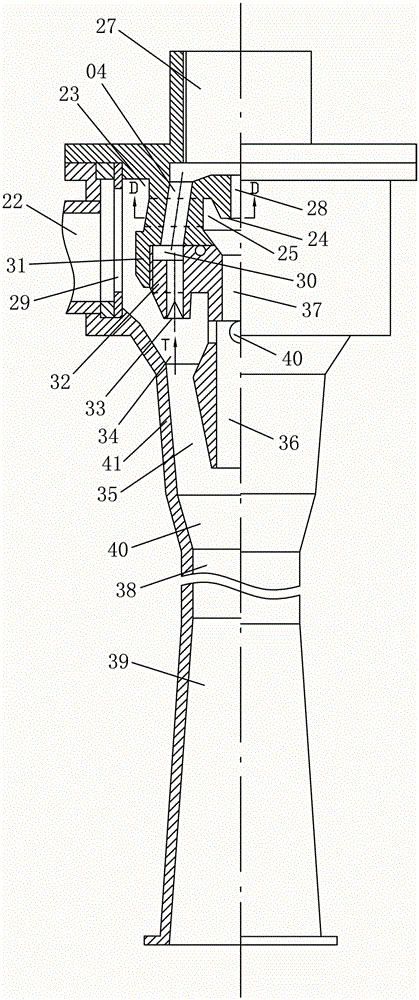

A vacuum vapor compression distillation sea water desalination device

InactiveCN103387270AIncrease water production rateIncrease heat and mass transfer rateGeneral water supply conservationSeawater treatmentWater desalinationSteam condensation

The present invention relates to a vacuum vapor compression distillation sea water desalination device comprising: a sea water pump, a seal chamber, a vacuum evaporation chamber and a vacuum pump and other components. In operation, a drive shaft drives the vacuum evaporation chamber filled with fresh water to rotate, after the formation of a vacuum area without water, sea water is fed in, and at the same time working vapor is fed in a vapor pipe coil, heat transfer between the vapor in the vapor pipe coil and the outside sea water enable the condensation of the vapor to obtain fresh water, while the sea water volatilizes to form primary vapor; and after temperature and pressure rise via a impeller, the primary vapor is fed in the vapor pipe coil as the working vapor for continuous vapor compression distillation to achieve sea water desalination. According to the device of the invention, centrifugal force is employed to replace the gravity to obtain a vacuum environment, operations are all in room temperature, no external heat source is required, and circular energy supply is achieved by the utilization of latent heat of the vapor; the water production rate and the energy utilization rate of the system are high; and the device has advantages of a simple process, a compact structure, little corrosion and scaling, etc.

Owner:HAINAN UNIVERSITY +1

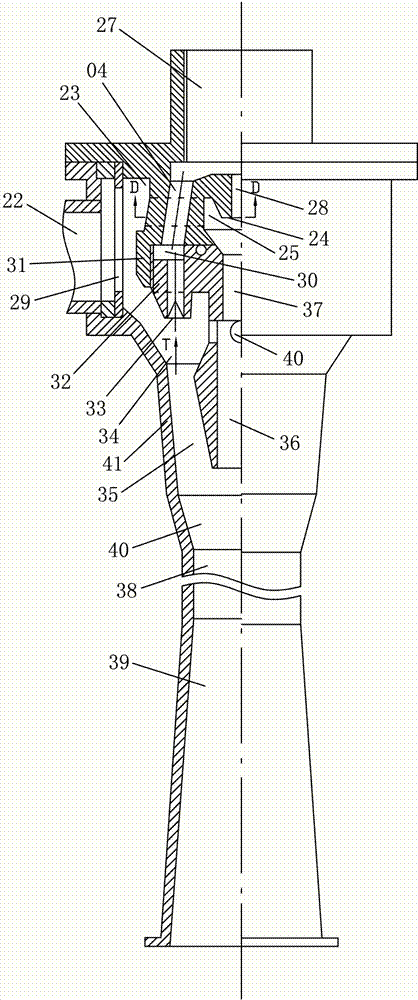

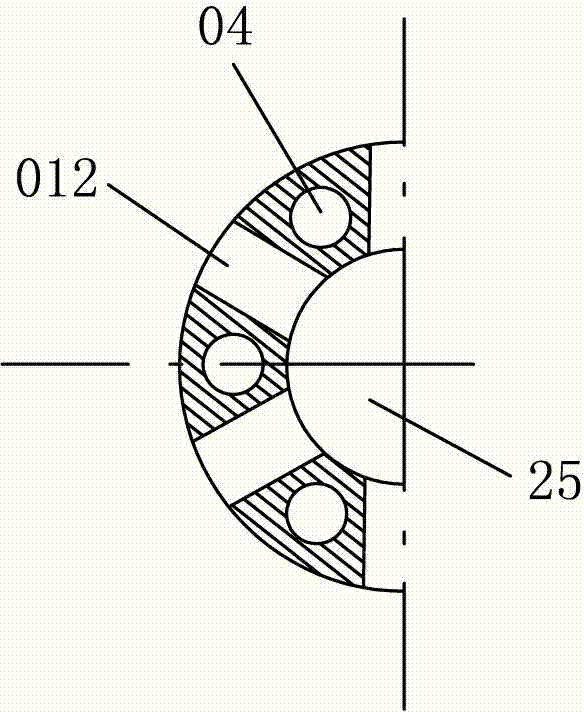

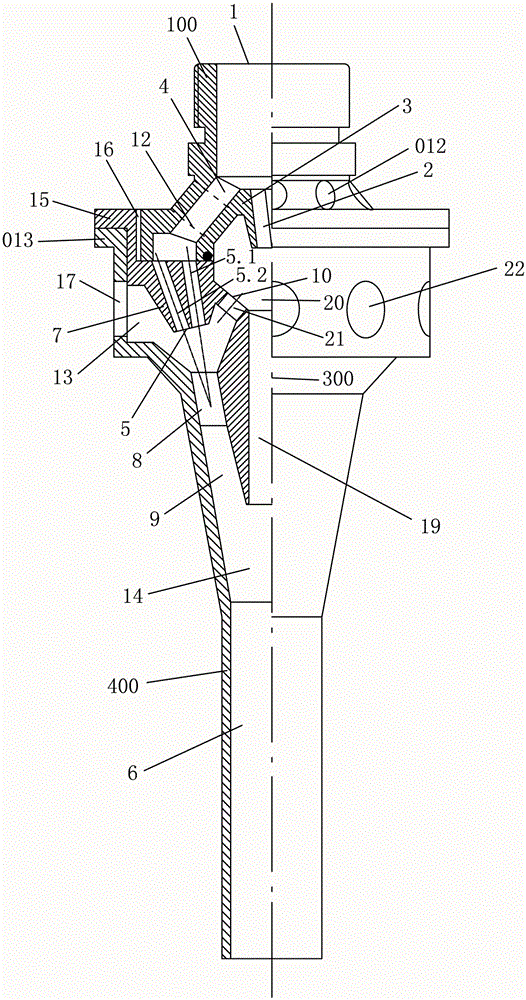

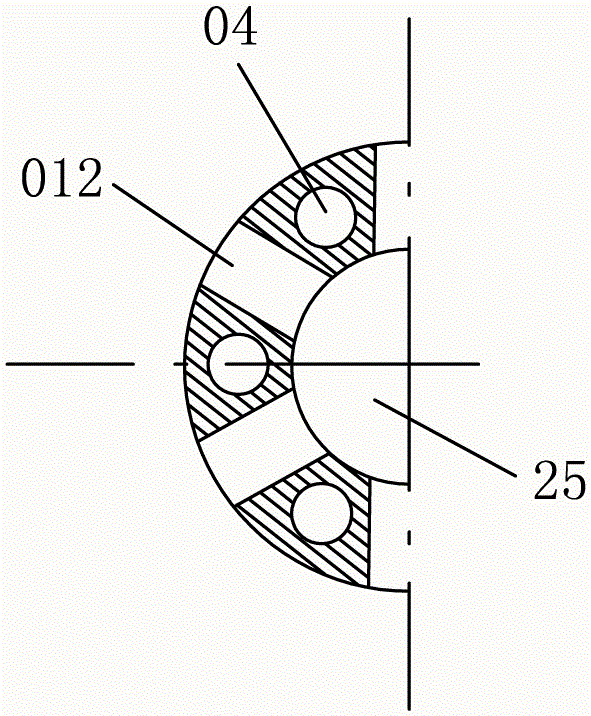

Jet pump

InactiveCN102654145ANovel structureUnique structureJet pumpsMachines/enginesSuction forceEngineering

The invention provides a jet pump, and relates to a mixed flow jet apparatus. The jet pump is composed of a current distributing assembly, an inner pipe assembly and an outer sleeve assembly which have a same shaft core, wherein the current distributing assembly and the inner pipe assembly are fixedly connected in series, thereby forming a blind top centre cavity and a centre mixing tube; the outer sleeve assembly is sleeved outside the current distributing assembly and the inner pipe assembly, thereby forming an annular mixing chamber, an annular mixing pipe, a total mixing chamber and a total mixing output pipe; an internal ring nozzle and an external ring nozzle are arranged between the current distributing assembly and the inner pipe assembly, a mainstream body sprayed by the internal ring nozzle carries out jet-suction on a secondary fluid of the blind top centre cavity so as to spray to the centre mixing tube, and the secondary fluid is mixed in the centre mixing tube so as to output a centre mixed flow; a mainstream body sprayed by the external ring nozzle carries out jet-suction on a secondary fluid of the blind top centre cavity so as to spray to the annular mixing pipe, and the secondary fluid is mixed in the annular mixing pipe so as to output an annular mixed flow; and the two mixed flows are mutually injected to enter the total mixing chamber and the total mixing output pipe so as to further output in an isotrope voltage-sharing manner. The jet pump provided by the invention has the advantages of smaller weight and axial direction size, high injection rate, great suction force and good property in large flow.

Owner:韩铁夫

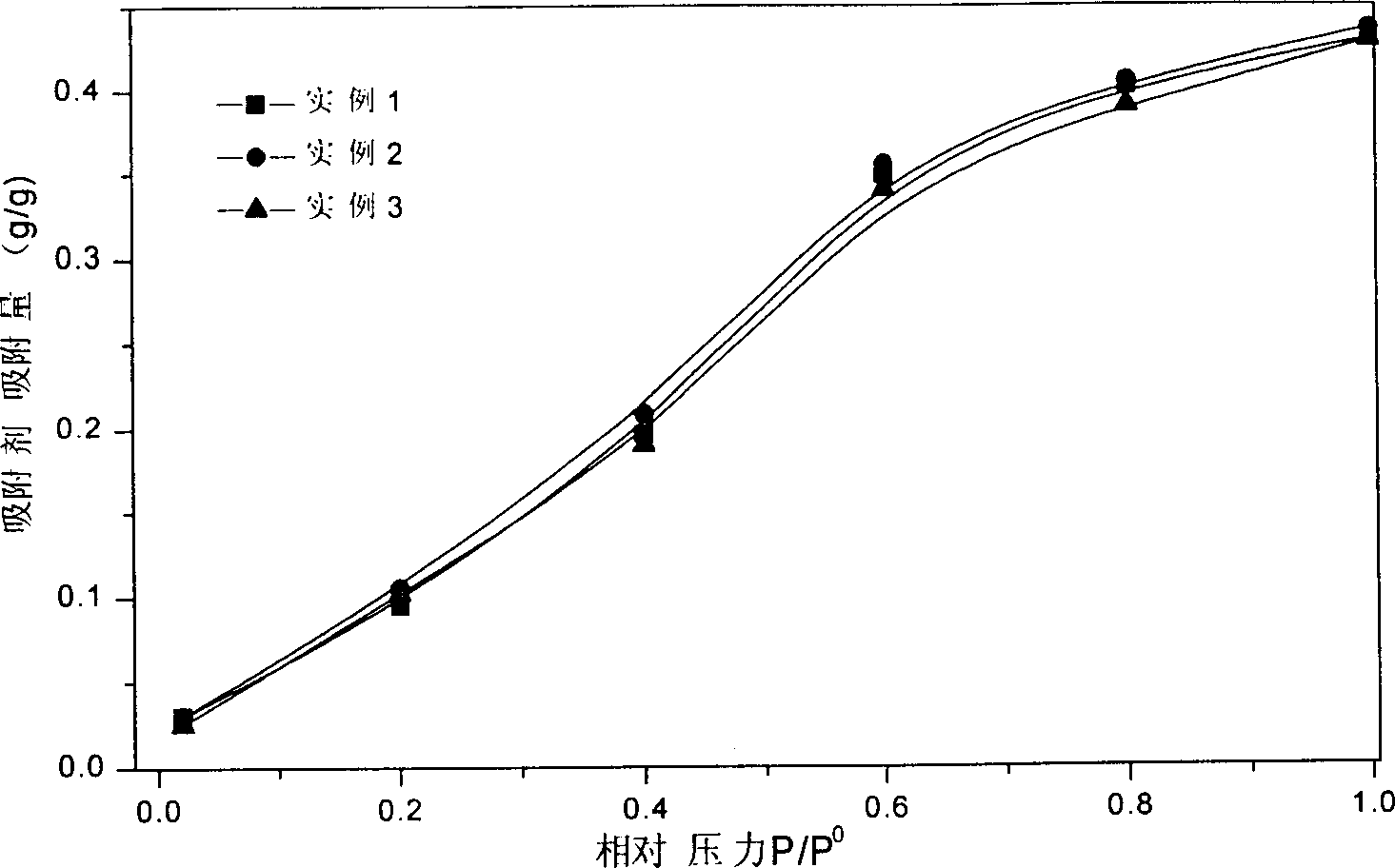

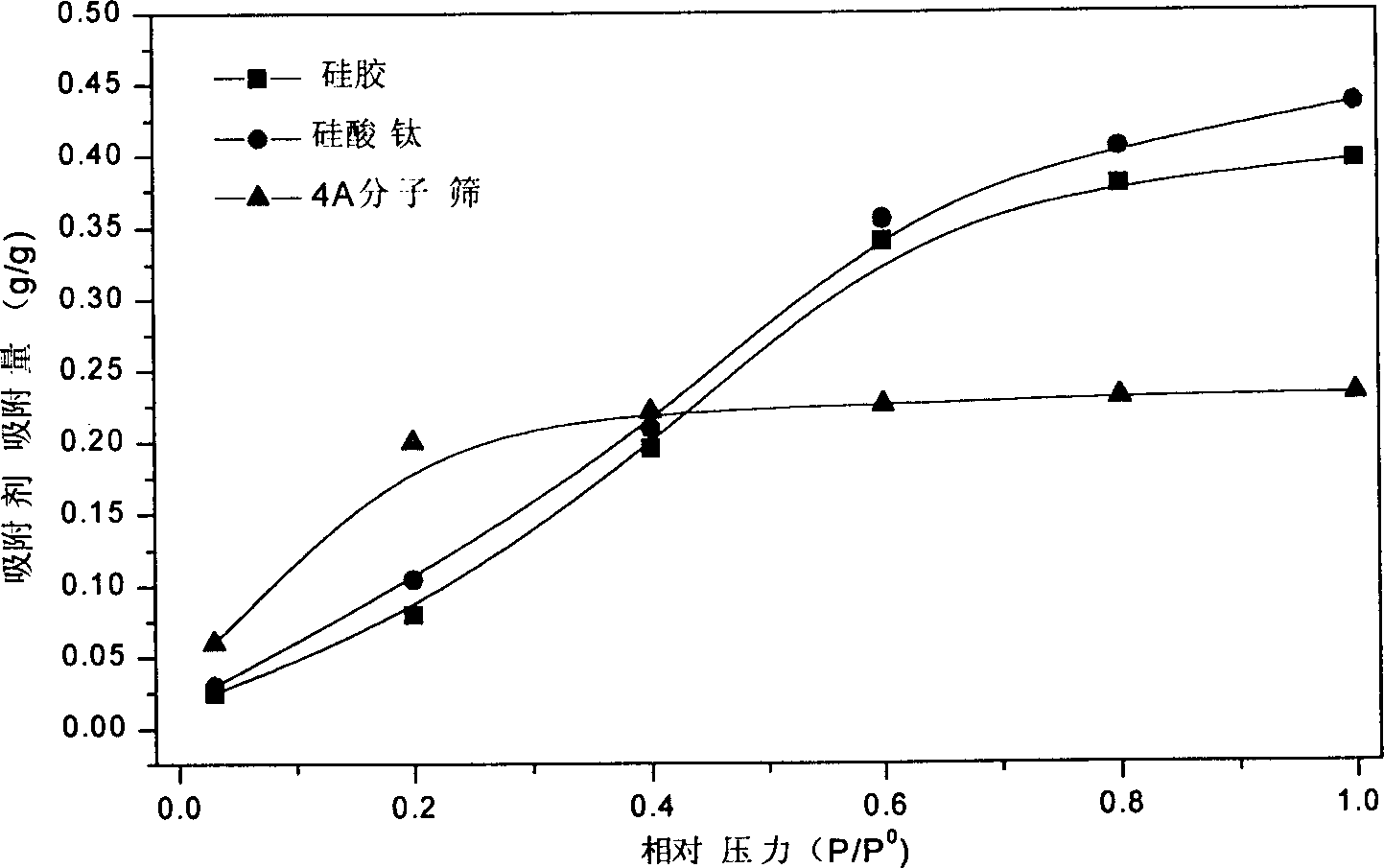

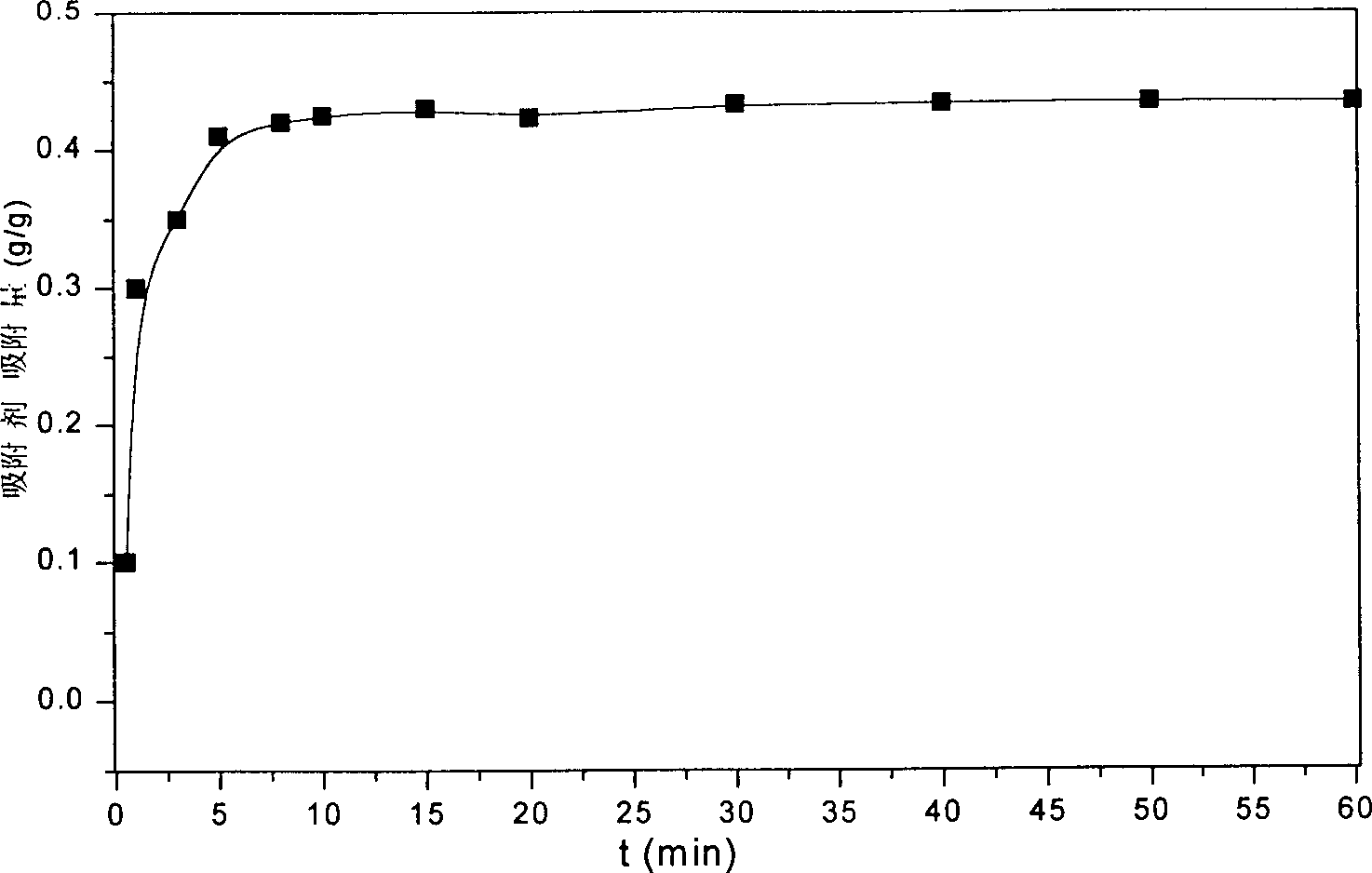

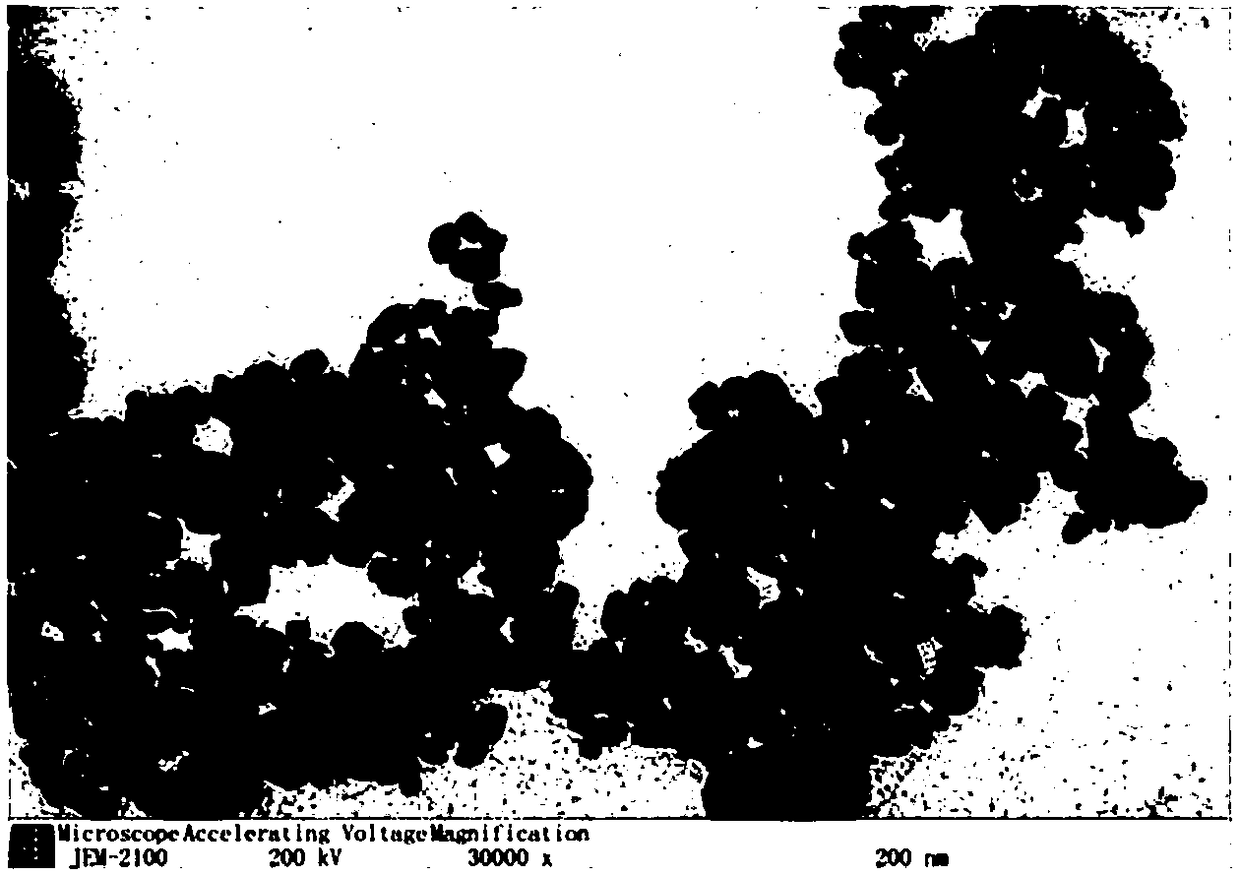

Prepn and application of titanium silicate adsorbent with high adsorption performance

InactiveCN1387942AImprove toughnessHigh rotational speed, corresponding energy requirements for turning the dehumidification wheelOther chemical processesSilicon compoundsPartial hydrolysisSorbent

The material for preparing titanium silicate adsorbent has molar ratio between Si and Ti of 8-20,and the proportion among alkoxide, water and polyethylene glycol of 1 to 5-15 to 0.002-0.005. The preparation includes the steps of sol preparation and titanium silicate preparation. The sol preparation includes partial hydrolysis of ethanol solution of silanolate, adding ethanol solution of titanic alkoxide while heating for complete hydrolysis; and adding polyethylene glycol for condensation to form sol. In the titanium silicate preparation, the sol is prepared into hydrogel through oil-free formation process and the hydrogel is then prepared into nano spherical titanium silicate via washing, drying and sieving. The titanium silicate product has high adsorption performance and is used in producing core of dehumidifying wheel.

Owner:SOUTH CHINA UNIV OF TECH

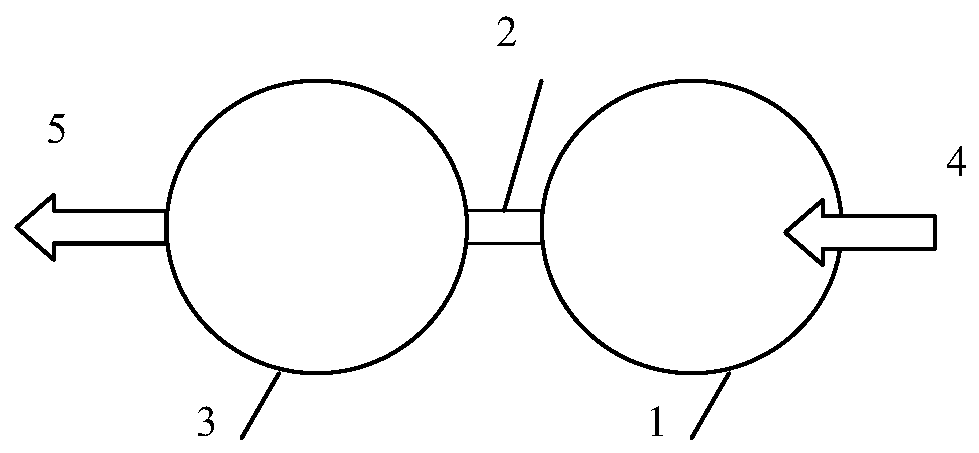

Injection mixer

InactiveCN102954047ASolve the problem of low ejection efficiencyReduce weightFlow mixersTransportation and packagingEngineeringInjection rate

The invention discloses an injection mixer which comprises a central injector, an outer ring injector and an overall injector, wherein the central injector is coaxially arranged in the outer ring injector, the front parts of the central injector and the outer ring injector are concentrically fixed, and the middle rear parts of the central injector and the outer ring injector are concentrically nested; and an output port of the outer ring injector is wound around an output nozzle of the central injector, and the outer ring injector and the central injector are jointly led to an overall mixing chamber of the overall injector and an overall mixing tube thereof. Compared with the prior art, the injection mixer disclosed by the invention is smaller in weight and axial size, high in injection rate, and good in large flow performance.

Owner:韩铁夫

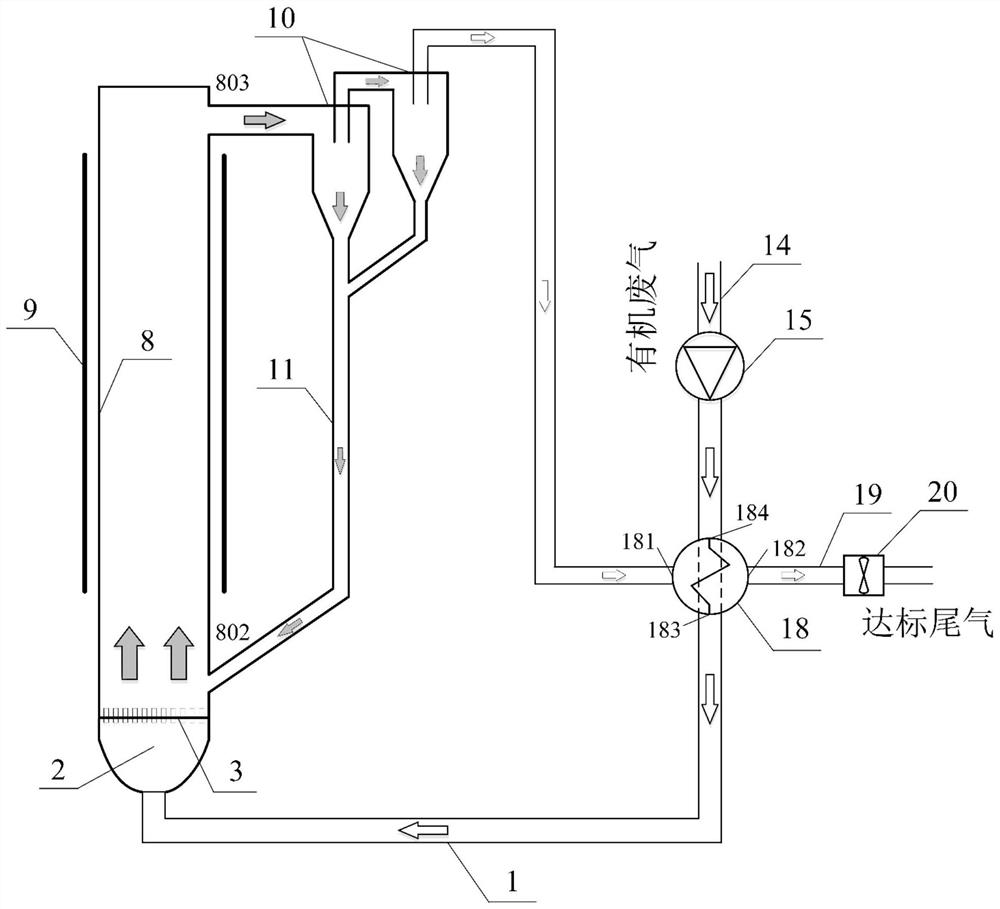

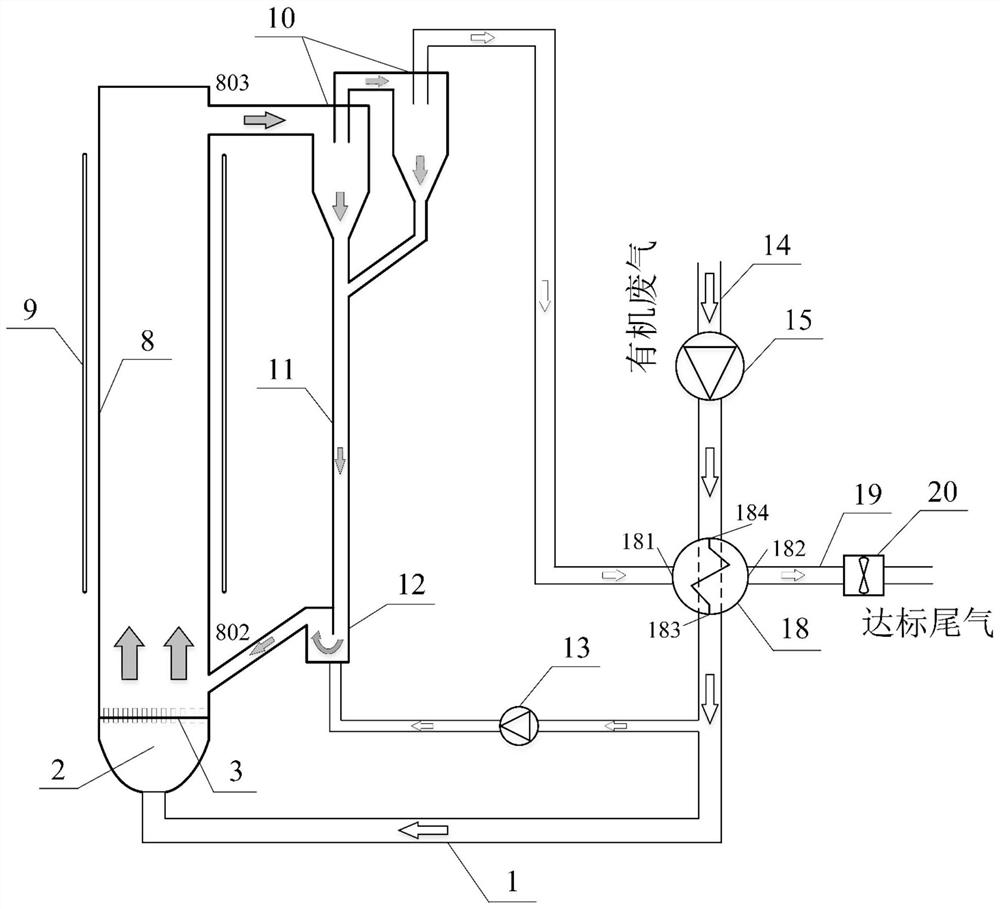

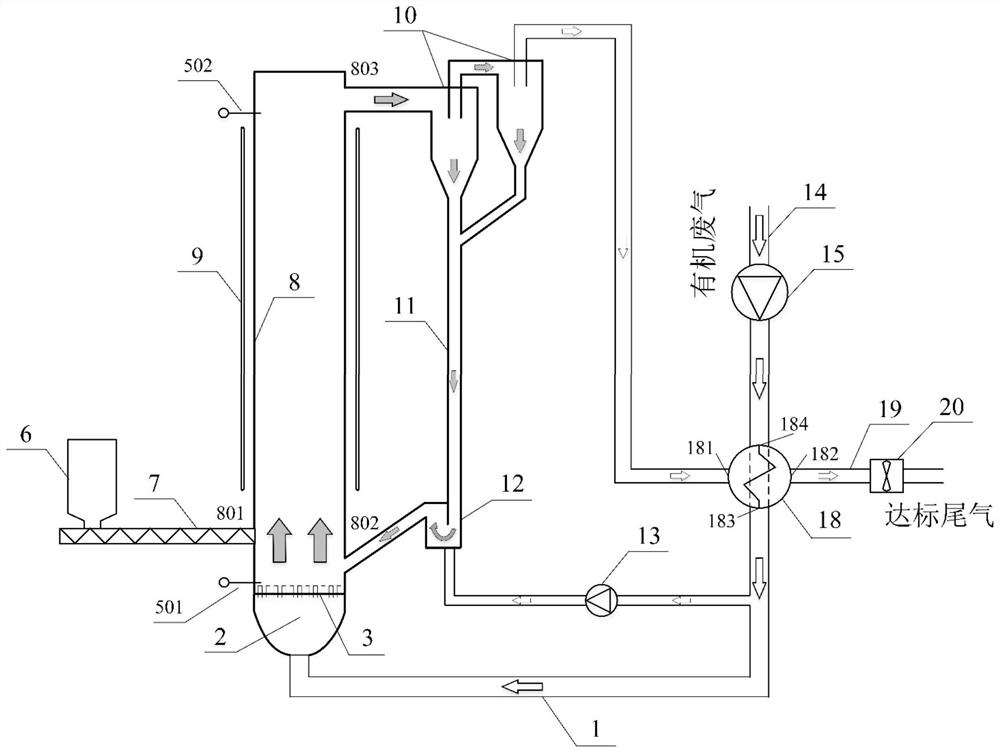

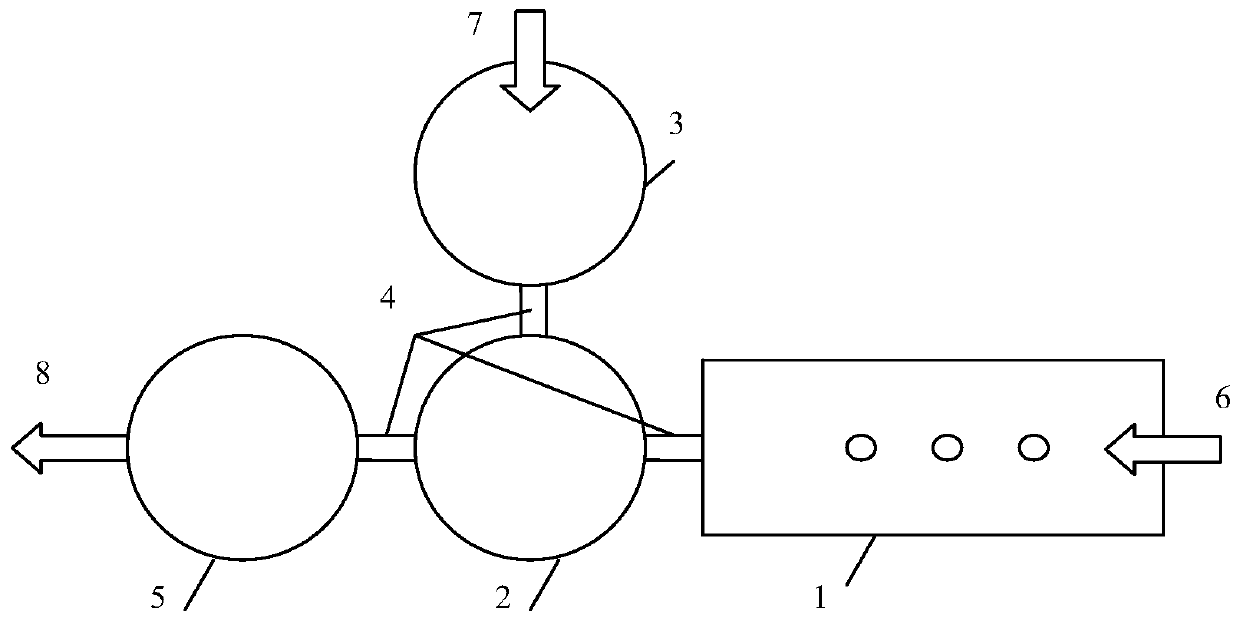

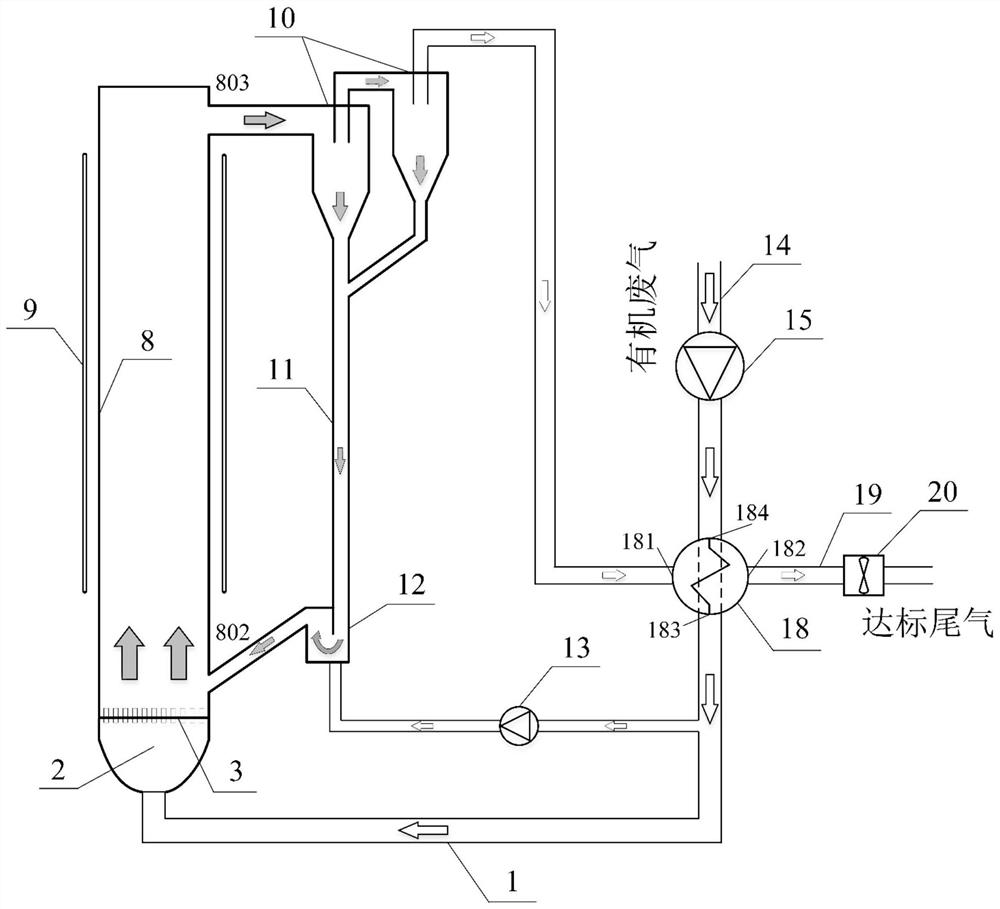

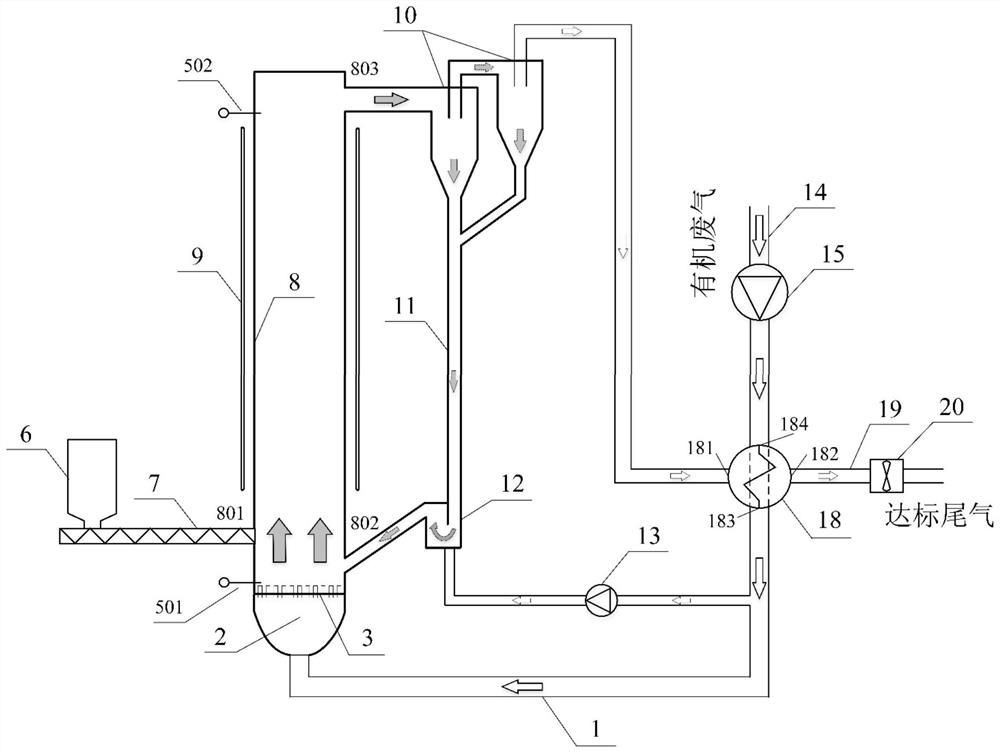

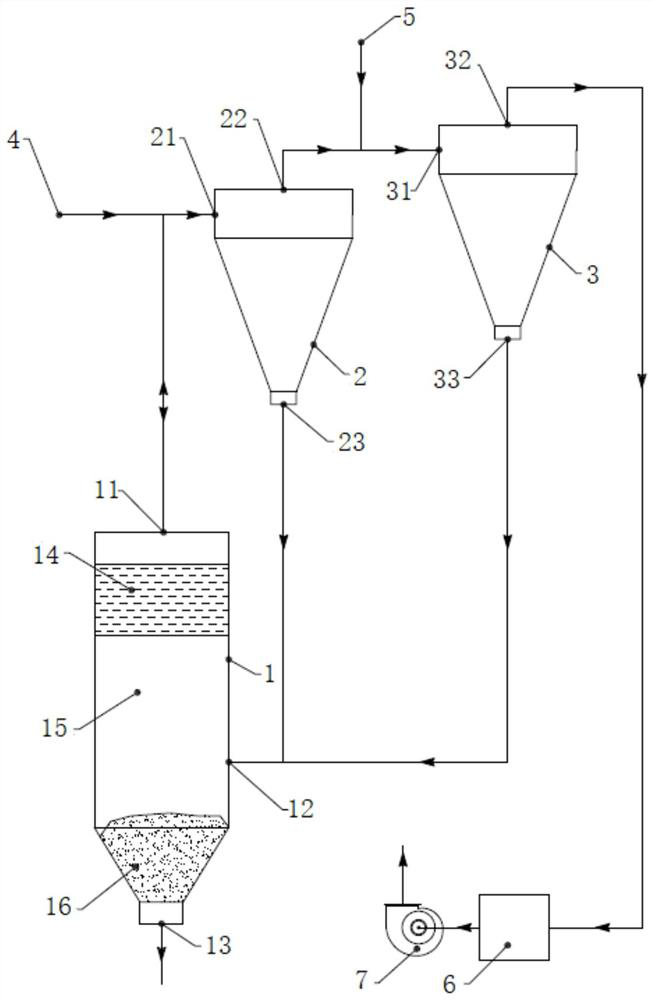

Circulating fluidized bed catalytic combustion method for treating organic waste gas

PendingCN111853834AIncreased gas-solid contact areaReduce consumptionIncinerator apparatusPtru catalystFluidized bed

The invention discloses a circulating fluidized bed catalytic combustion method for treating organic waste gas, and belongs to the field of environmental protection. The method comprises the followingsteps that A, the temperature of a raising pipe in a circulating fluidized bed catalytic combustion furnace is controlled within the set catalytic combustion temperature range; B, the organic waste gas to be treated is sent from a raising pipe intake manifold into the raising pipe, so that catalyst particles in the raising pipe are fluidized rapidly, and at the same time, VOCs components in the organic waste gas to be treated are catalyzed for oxidative decomposition; C, airflow after oxidative decomposition entrains part of the catalyst particles to move upwards into a separator, the catalyst particles are separated and return to the raising pipe through diplegs, and hot exhaust gas after purifying leaves the separator; and D, the hot exhaust gas after purifying enters a heat exchanger for exchanging heat to utilize exhaust gas heat, and the exhaust gas after heat exchange merges into an exhaust gas flue and is introduced into a factory exhaust manifold or exhausted into the atmosphere. The method is high in removal rate, simple in operation and high in heat utilization rate, and long-term continuous and stable operation of volatile organic waste gas can be achieved.

Owner:JIANGSU NANFANG COATING & ENVIRONMENT PROTECTION EQUIP +1

Supersonic wave-intensified far-infrared radiation drying method

ActiveCN104000277AIncrease heat and mass transfer rateAvoid churnDead plant preservationFood preservationChlorogenic acidCavitation

The invention discloses a supersonic wave-intensified far-infrared radiation drying method. The supersonic wave-intensified far-infrared radiation drying method utilizes far-infrared radiation and supersonic wave radiation to realize drying treatment on a material to be treated. The supersonic wave-intensified far-infrared radiation drying method utilizes supersonic wave-intensified assistantly far-infrared radiation drying, cavitation and mechanical effects produced by supersonic wave produce intensification effects on heat and mass transfer rates and enzymatic inactivation mechanism of the far-infrared radiation, synchronous dehydration and enzymatic inactivation of a material containing a sensitive enzyme-like substance are realized, and based on high-efficiency drying, an effective component or nutrient loss caused by enzymatic browning and appearance and quality deterioration are avoided. Aiming at honeysuckle flower, the supersonic wave-intensified assistantly far-infrared radiation is used for synergetic drying so that moisture-containing solids and heat and mass transfer rates in a cavity are improved, polyphenol oxidase synchronous inactivation efficiency of far-infrared heat effect is improved, high-efficiency and high-quality synchronous dehydration and enzymatic inactivation of honeysuckle flower are realized, a loss of chlorogenic acid in honeysuckle flower is avoided and dried honeysuckle flower quality is improved.

Owner:HENAN UNIV OF SCI & TECH

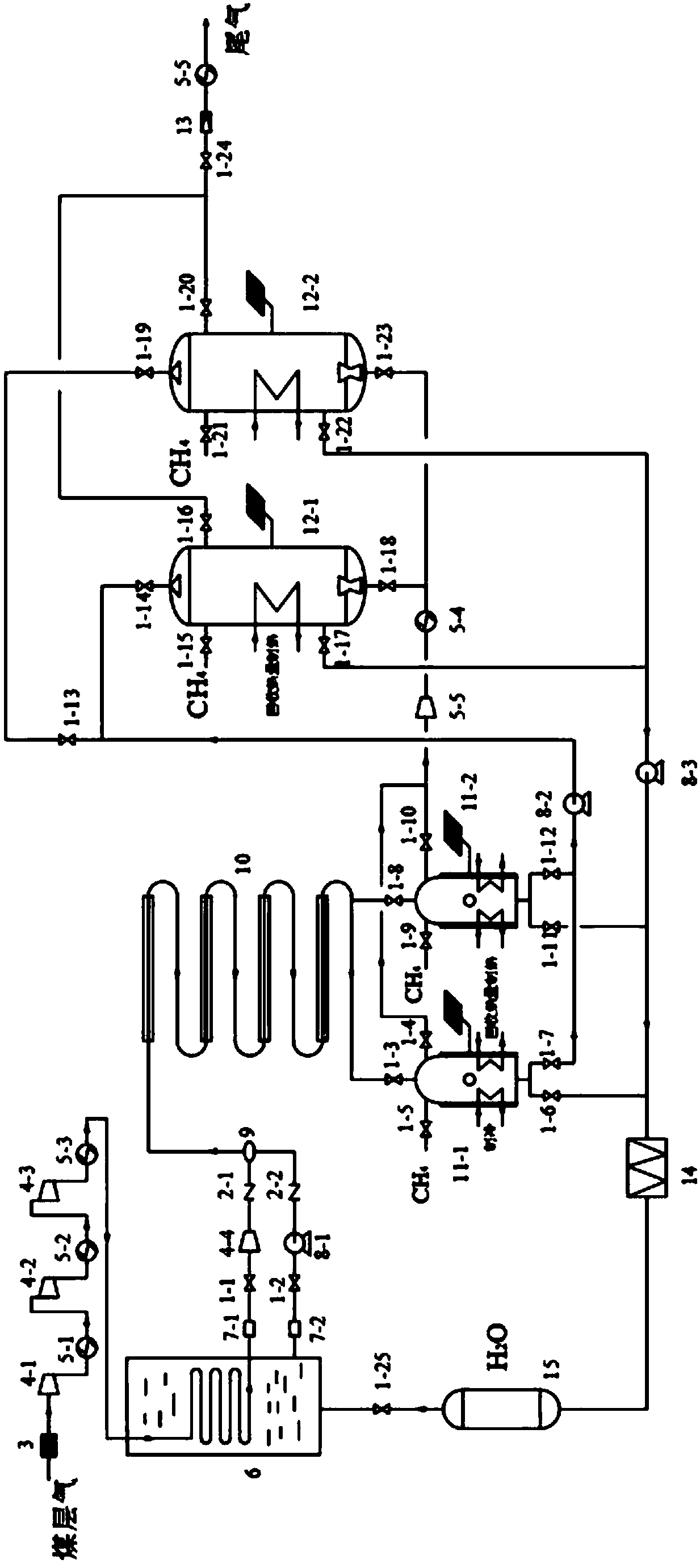

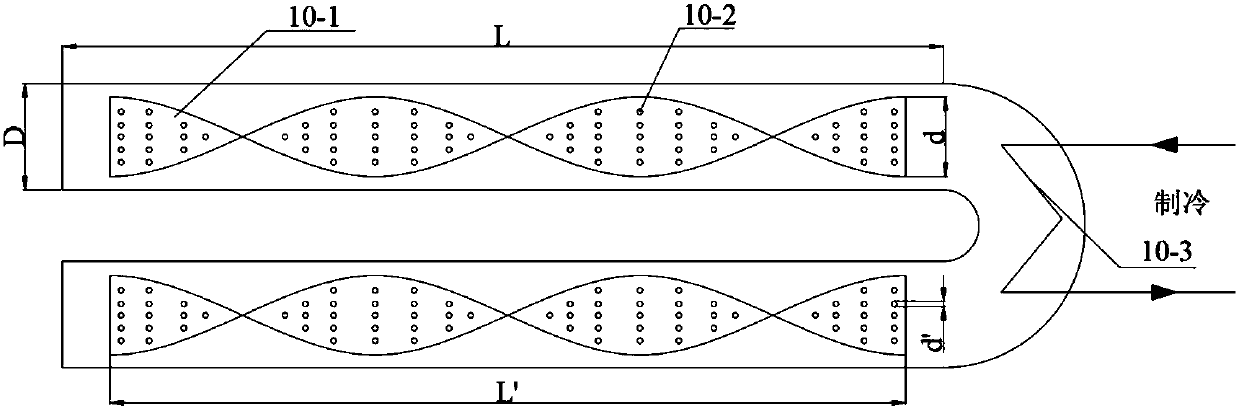

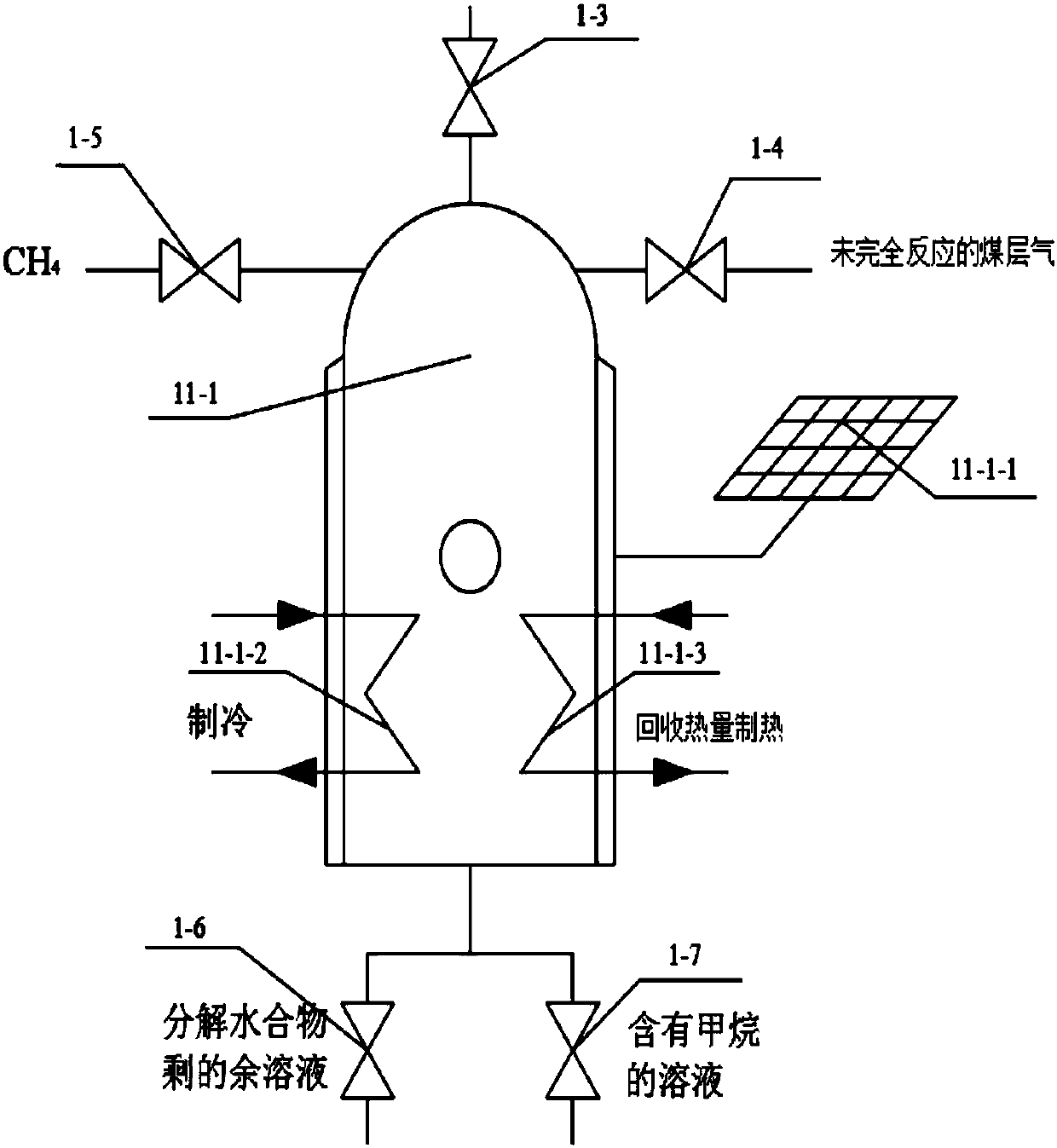

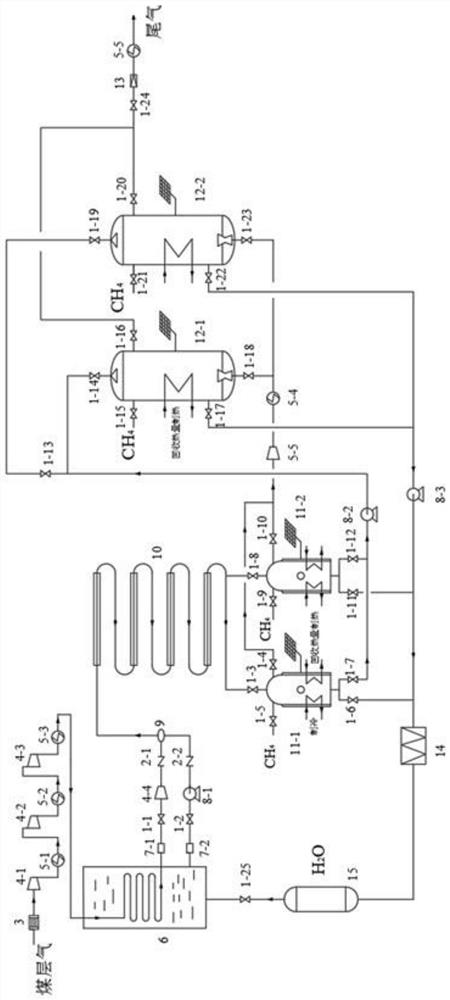

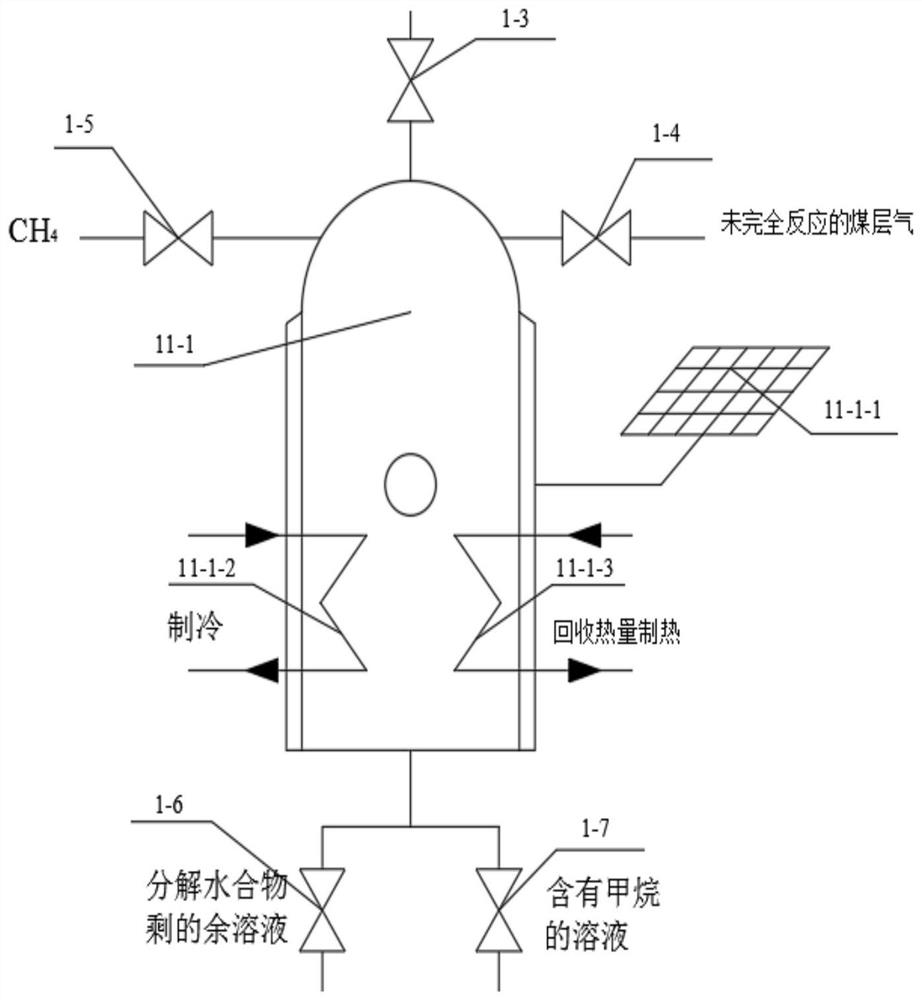

Device for continuously separating methane in coalbed methane-air mixture by using hydrate

ActiveCN107903969ATo achieve the purpose of energy saving and environmental protectionLow investment costGaseous fuelsDecompositionSlurry

The invention relates to the industrial field of petroleum natural gases and in particular to a device and a method for continuously separating methane in a coalbed methane-air mixture by using a hydrate. The device comprises one twisted strip hydrate preparation device and two laval hydrate preparation devices, wherein the twisted strip hydrate preparation device is used for improving heat and mass transfer through a twisted strip; the laval hydrate preparation devices are used for increasing supercooling degrees by using laval ejection tubes; two three-phase separation devices are arranged behind the twisted strip hydrate preparation device; one three-phase separation device is at a storage state; another one three-phase separation device is at an hydrate decomposition state; and the twostates can be transformed into each other. Through spiral flows generated by the twisted strip, the hydrate can be fed into the three-phase separation devices in a pulp manner without being blocked in the twisted strip hydrate preparation device; a coalbed gas which is not completely reacted is fed into the laval hydrate preparation devices, then methane hydrate generation conditions are met, andmethane in the coalbed gas can be further extracted; the two laval hydrate preparation devices at a preparation state and a decomposition state are available, and through transforming of the two states, an industrial requirement of continuous hydrate preparation is met.

Owner:CHANGZHOU UNIV

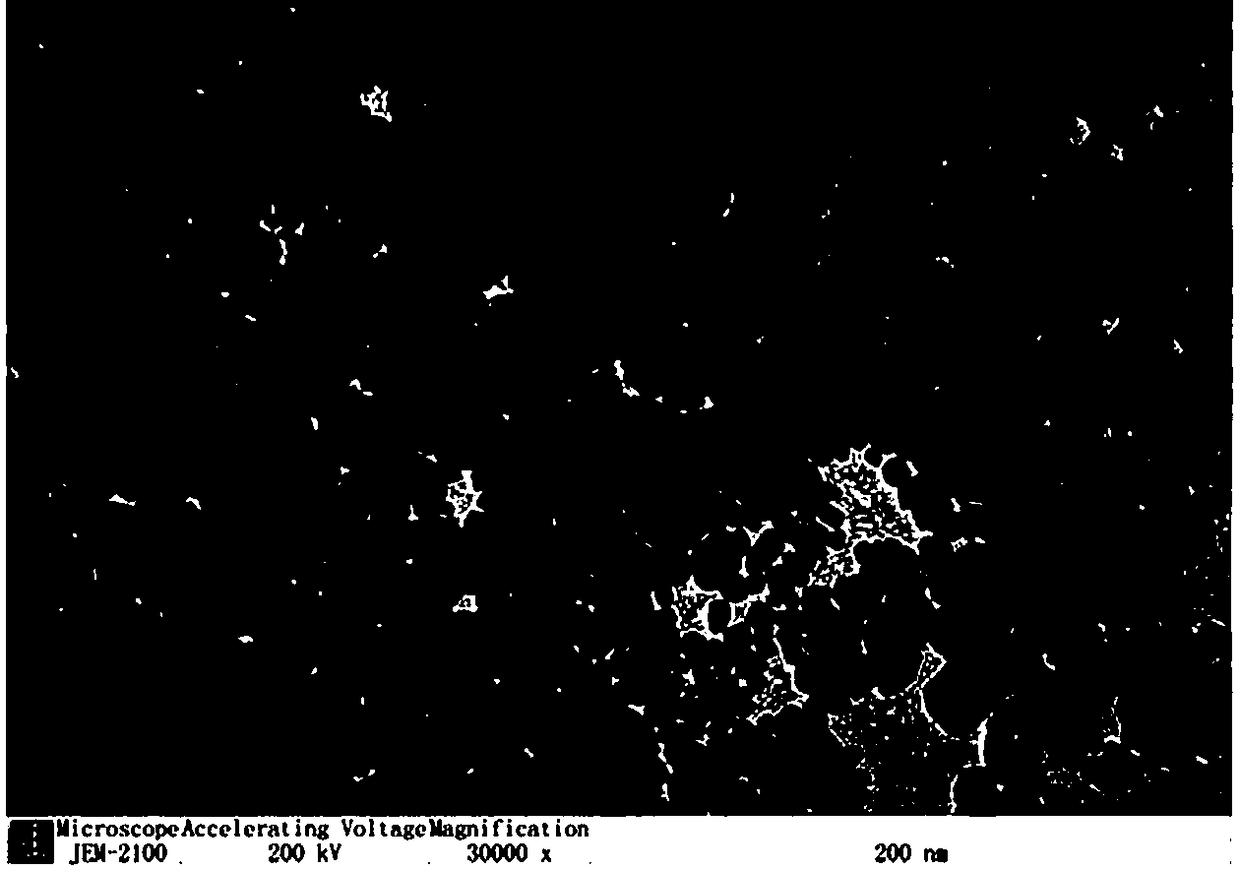

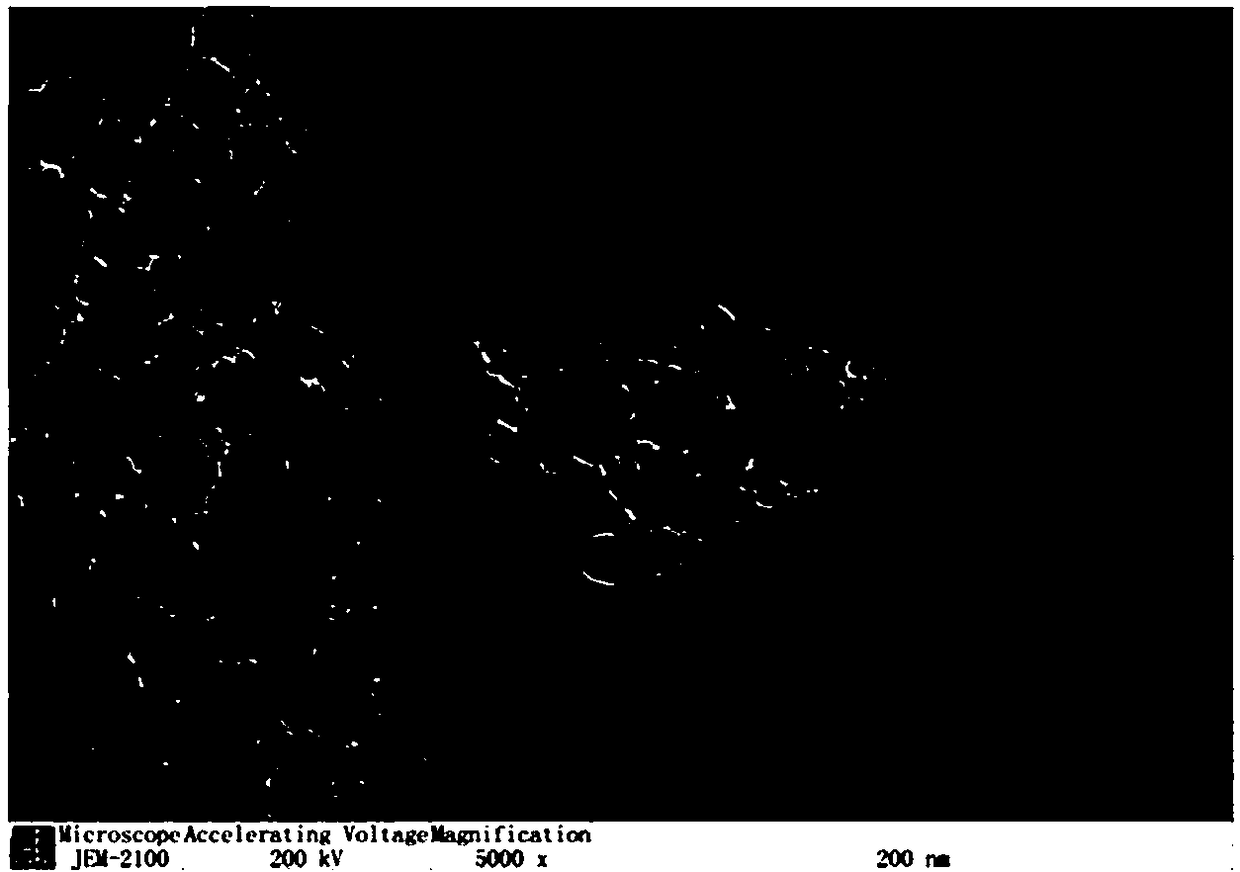

Method for efficiently preparing nano barium sulfate with uniform particles

InactiveCN108726554ASmall particle sizeNarrow particle size distributionMaterial nanotechnologyCalcium/strontium/barium sulfatesDispersityAfter treatment

The invention discloses a method for efficiently preparing nano barium sulfate with uniform particles. Soluble BaS raw ore is used as a raw material to prepare the nano barium sulfate by virtue of pretreatment, main reaction and after-treatment. The method specifically comprises the following steps: adding the raw material soluble BaS raw ore into deionized water, dissolving to obtain a 0.1 to 5 mol / L BaS solution, wherein the BaS solution is used as a reaction solution a for standby use; preparing a sulfuric acid solution with the same concentration as the reaction solution a, wherein the sulfuric acid solution is a reaction solution b which is used for the standby use; pumping the reaction solution a and the reaction solution b into a micro reactor to react at a speed of 50 to 150 ml / min, standing for 0.1 to 20 s in the micro reactor, collecting a product c at an outlet of the micro reactor, and recovering H2S gas generated in the main reaction; and centrifuging, washing and drying the product c to obtain a target object nano barium sulfate with uniform particles. The nano barium sulfate product prepared by the method has the characteristics of uniformity in size distribution, good dispersity, narrow distribution of particle size and the like, and the particle size of the product is in a range of 30 to 50 nm.

Owner:KUNMING UNIV OF SCI & TECH

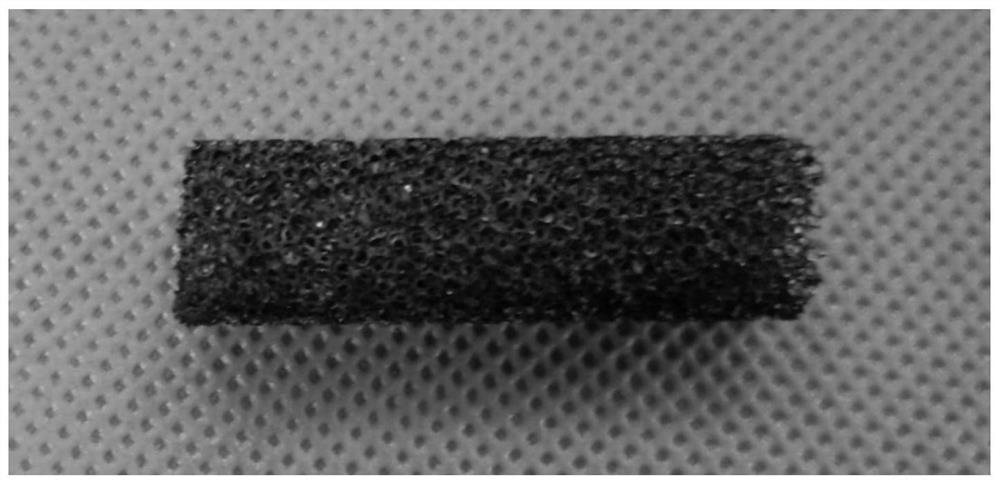

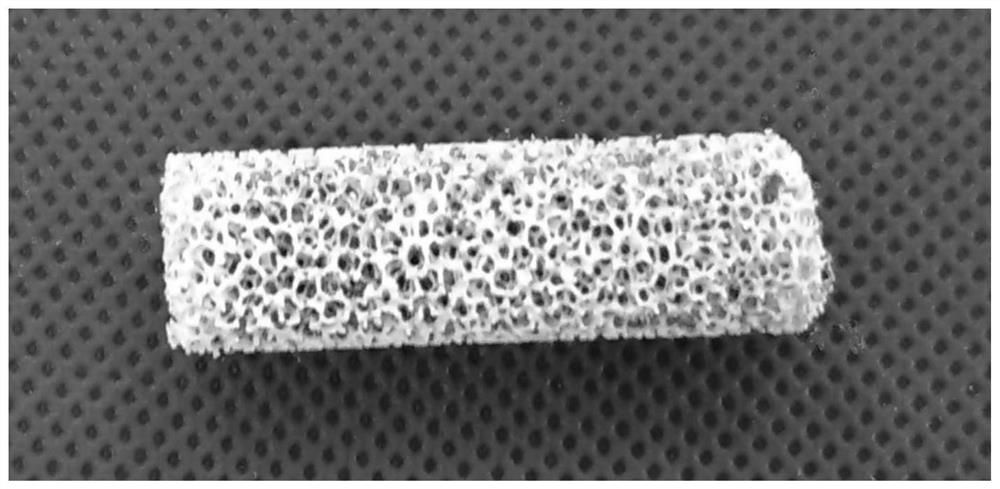

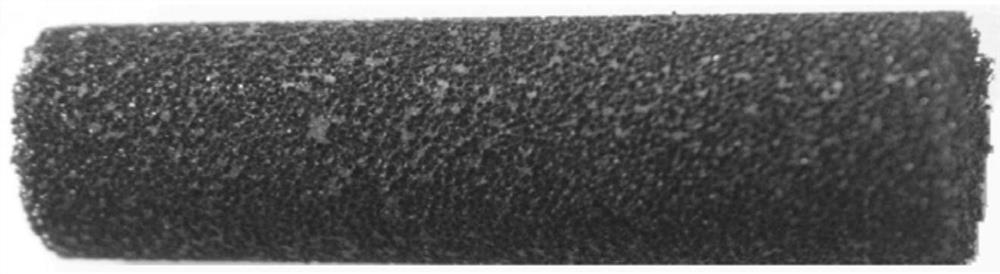

Preparation method of SiC foam, SiC foam monolithic catalyst for catalytic combustion of methane, and preparation method thereof

ActiveCN108686714AHigh strengthSmall thermal expansionCatalyst carriersCarbon compoundsChemistryPrecious metal

The invention discloses a preparation method of SiC foam, a SiC foam monolithic catalyst for catalytic combustion of methane, and a preparation method thereof. The SiC foam is prepared by following steps: placing vitreous state carbon foams in a polysilane solution, impregnating carbon foams, drying, and carrying out high temperature reactions. The SiC foam monolithic catalyst comprises SiC foams,a transition layer is deposited on the SiC foams, a second carrier is deposited on the transition layer, and precious metals are loaded on the second carrier. The preparation method comprises following steps: depositing the transition layer and the second carrier, carrying out a heat treatment, and loading precious metals. The preparation method of SiC foam has the advantages of simpleness and low cost, and obtained SiC foam is a promising catalyst carrier. The SiC foam monolithic catalyst has the advantages of high catalytic activity, high strength, high temperature resistance, high heat andmass transfer rate, and long service life, and is a novel promising methane catalyst. The preparation method has the advantages of simple technology, low cost, low equipment requirements, and safe operation.

Owner:NAT UNIV OF DEFENSE TECH

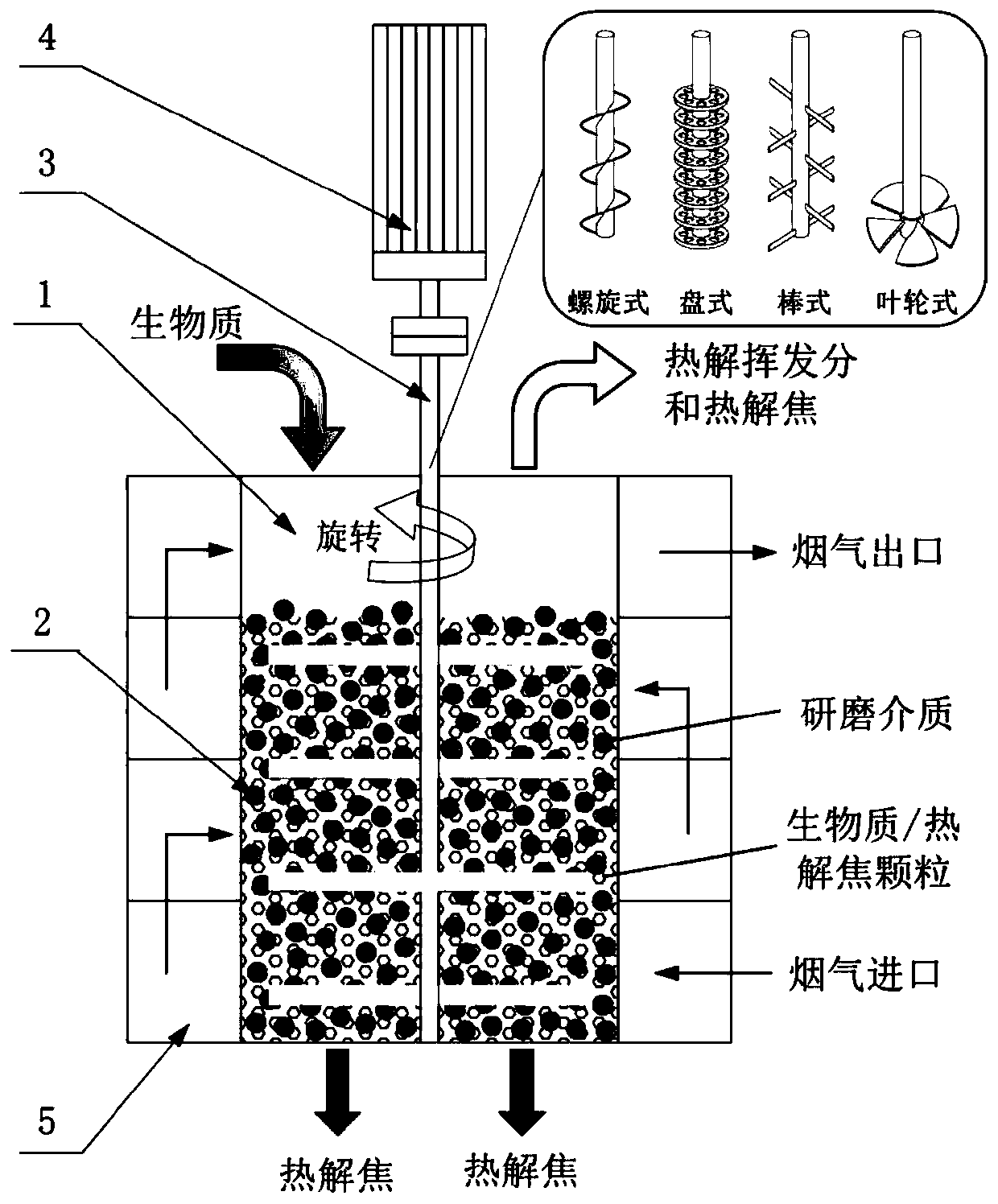

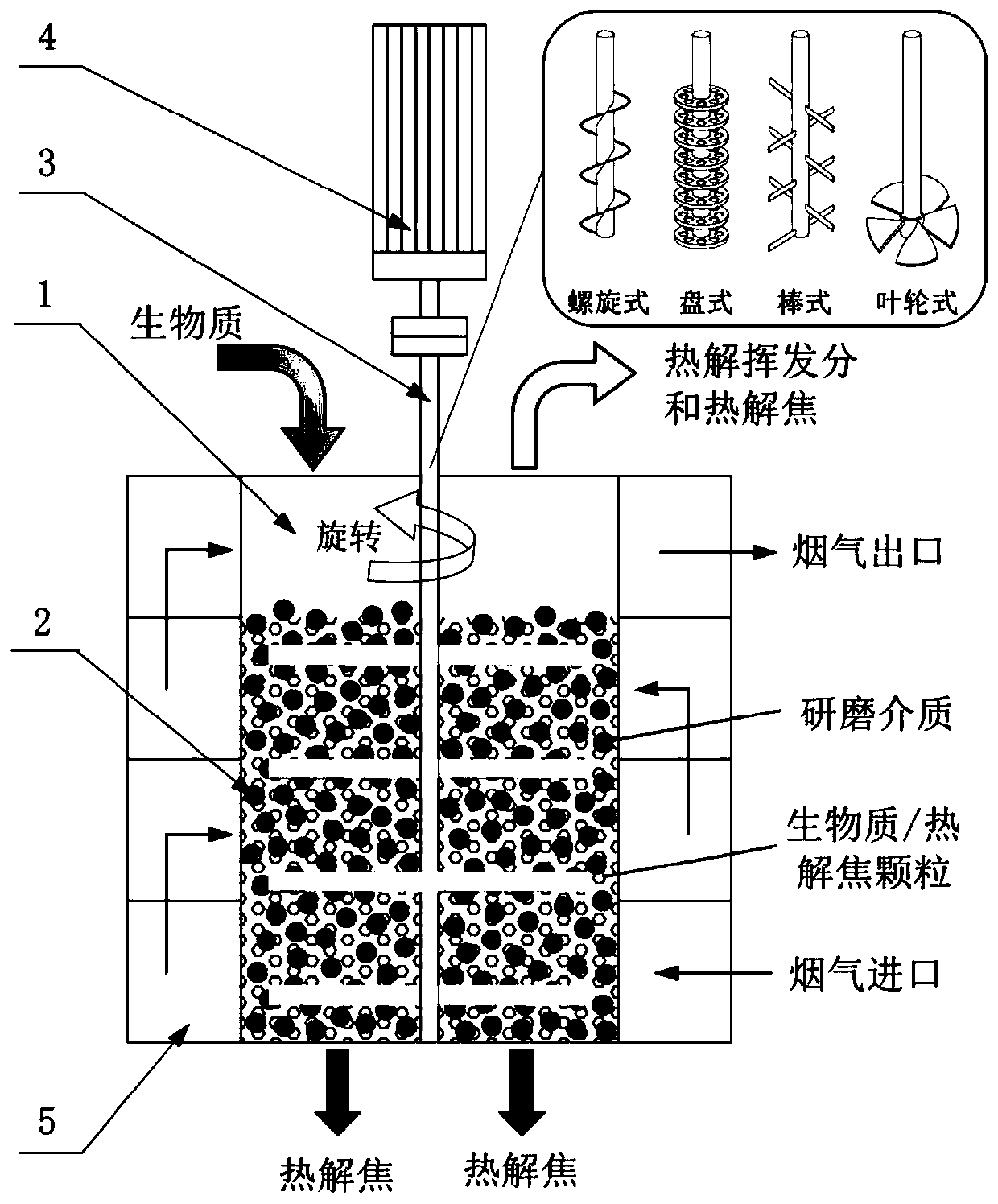

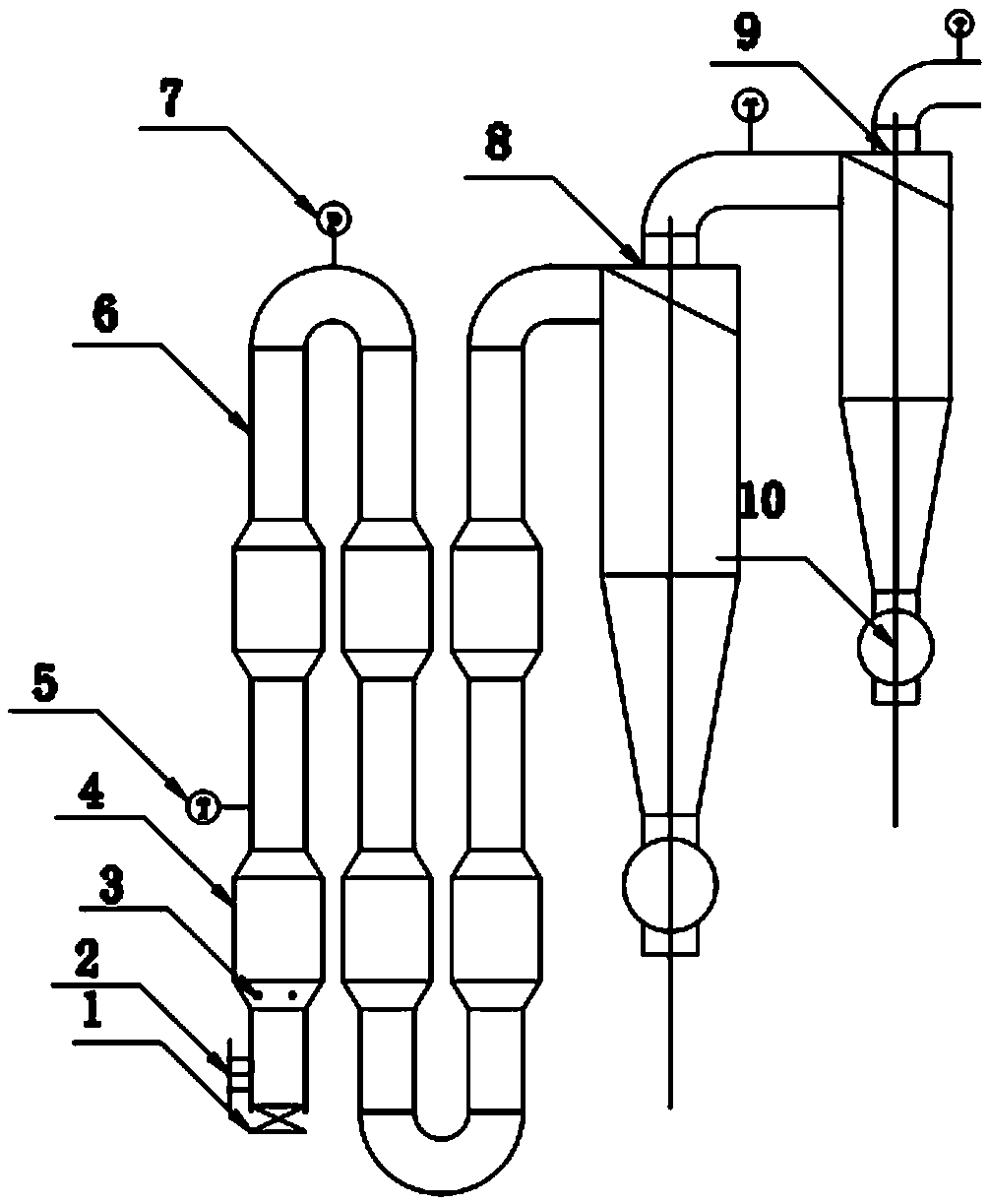

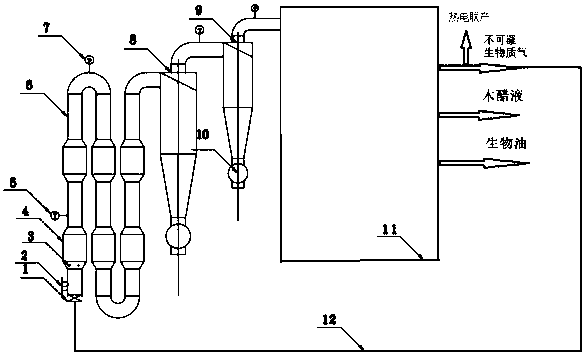

Vertical stirring, grinding and pyrolysis device

InactiveCN111117672AIncrease heat and mass transfer rateFast pyrolysisTransportation and packagingBiofuelsPyrolysisMaterials science

The invention discloses a vertical stirring and grinding pyrolysis device which comprises a pyrolysis reactor; a high-temperature smoke box is arranged around the pyrolysis reactor in a sleeving manner, and high-temperature smoke is input into the high-temperature smoke box, so that the pyrolysis reactor reaches the temperature required by pyrolysis; a stirring shaft and a grinding medium are arranged in the pyrolysis reactor; biomass particles are fed into the pyrolysis reactor; the stirring impeller of the stirring shaft is matched with the grinding medium to grind and fully pyrolyze biomassparticles in the pyrolysis reactor; the surfaces of the particles are rapidly heated, pyrolyzed and carbonized, volatile components are released, surface carbon is ground under the collision and shearing action of the grinding medium, the surfaces of fresh biomass are promoted to be exposed and rapidly pyrolyzed, and the process is repeated until the biomass particles are completely pyrolyzed andcrushed. According to the invention, direct and rapid pyrolysis liquefaction of large-particle biomass can be realized, the biomass crushing pretreatment cost is significantly reduced, and the deviceis simple, easy to amplify and good in technical economy.

Owner:JIANGSU UNIV

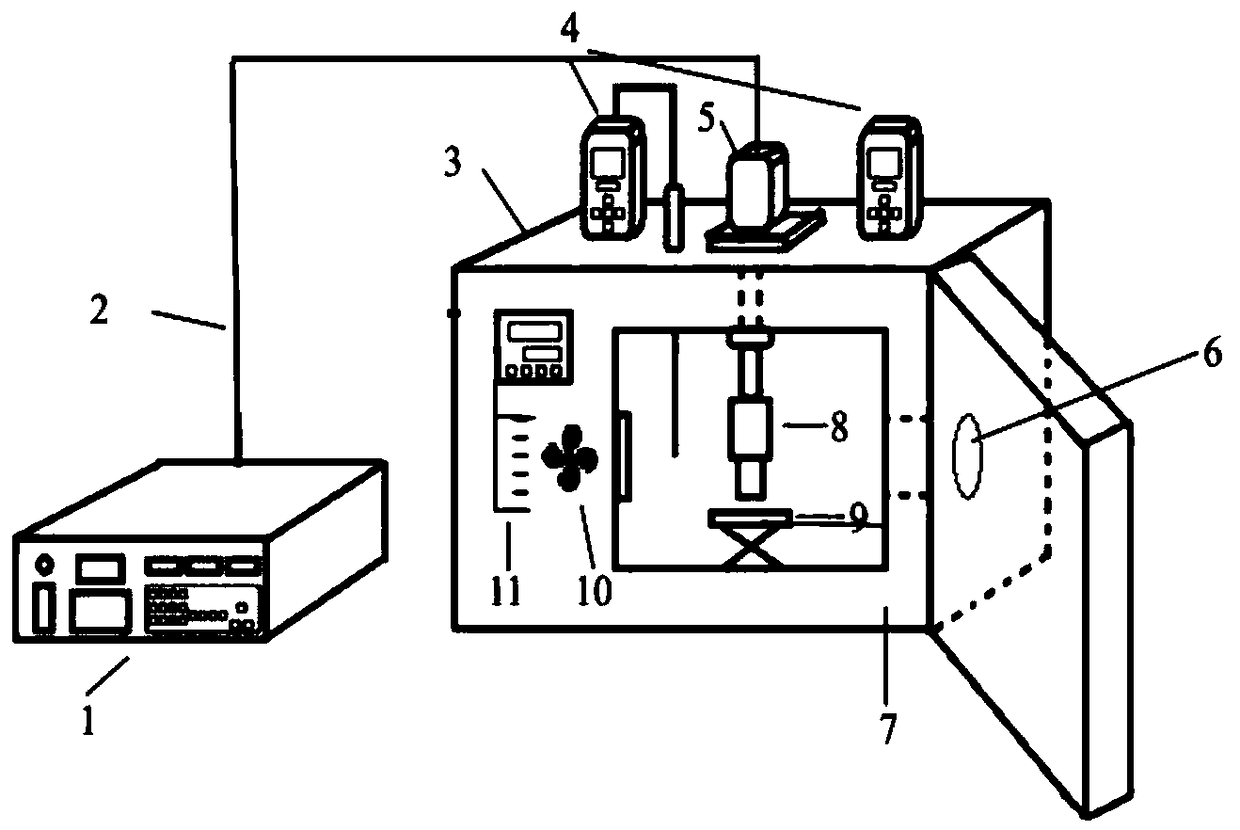

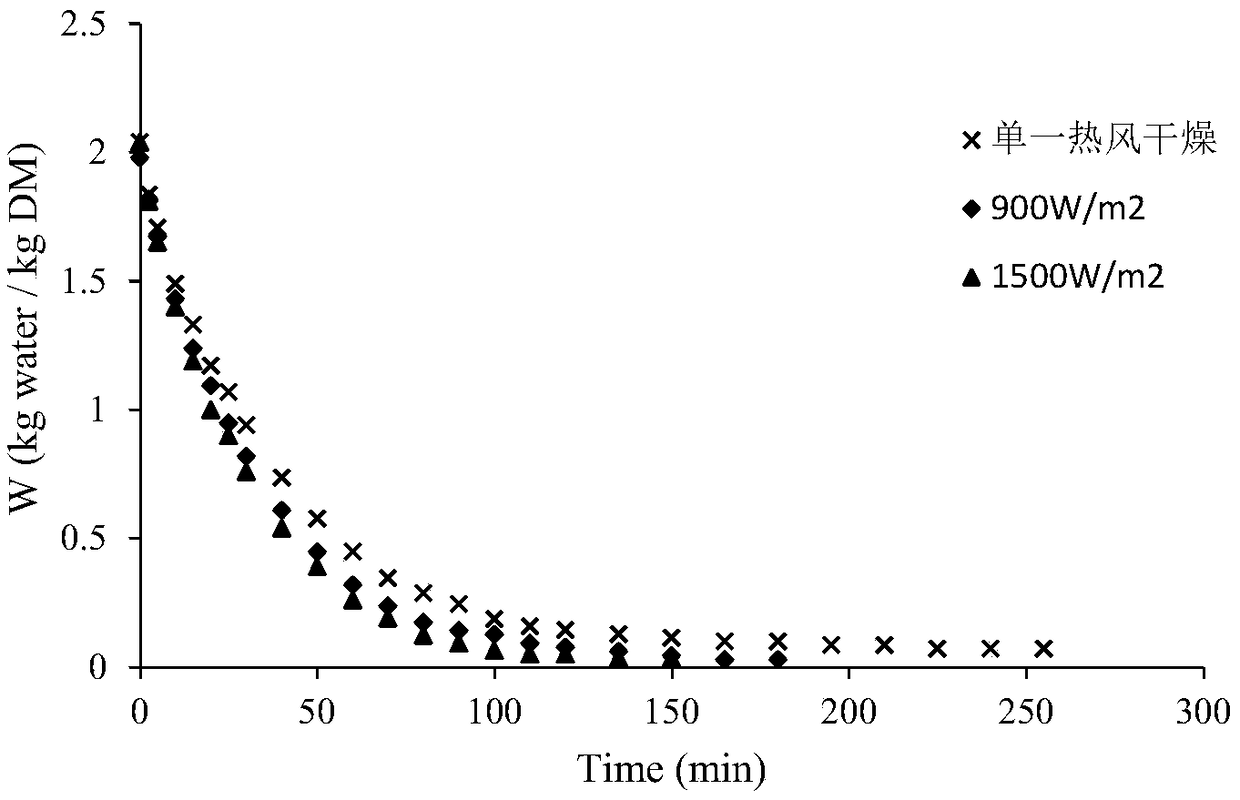

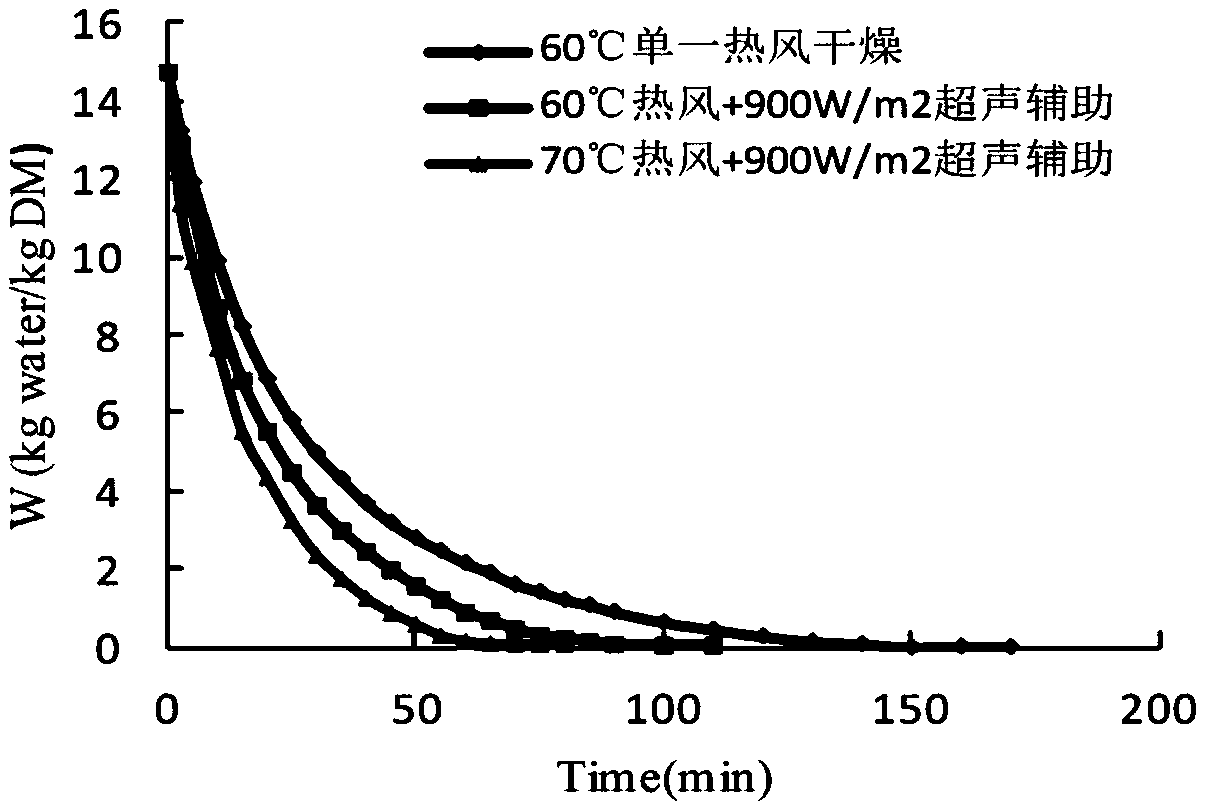

Method and drying device for drying fruits and vegetables through contact-type ultrasonic-assisted hot air drying mode and

InactiveCN108645125AShorten drying timeSpeed up the drying processDrying solid materials without heatDrying gas arrangementsUltrasonic assistedUltrasonic cavitation

The invention discloses a method and drying device for drying fruits and vegetables through a contact-type ultrasonic-assisted hot air drying mode. The method comprises the following steps that (1), the fruits and vegetables are preprocessed, wherein the fruits and vegetables are cleaned and sliced; and (2), ultrasonic-assisted hot air drying is carried out, wherein the processed fruits and vegetables are placed on a drying tray, a hot air drying device and an ultrasonic assistance drying device are sequentially turned on, an ultrasonic probe is located above the fruits and vegetables, the height of the drying tray is adjusted so that the fruits and vegetables directly make contact with the ultrasonic probe, and ultrasonic-assisted hot air drying is carried out on the fruits and vegetablesso as to obtain dehydrated fruits and vegetables. The method for drying the fruits and vegetables through the contact-type ultrasonic-assisted hot air drying mode adopts the combined action of ultrasonic cavitation, heat effect and mechanical effect, the quality and the structure of the materials are changed in the drying process, the hot air drying process is enhanced, the drying time of the fruits and vegetables is remarkably shortened, the drying time can be saved by 30%-60%, the product quality is effectively improved, and the nutrient loss of the dried fruits and vegetables is reduced.

Owner:NANJING AGRICULTURAL UNIVERSITY

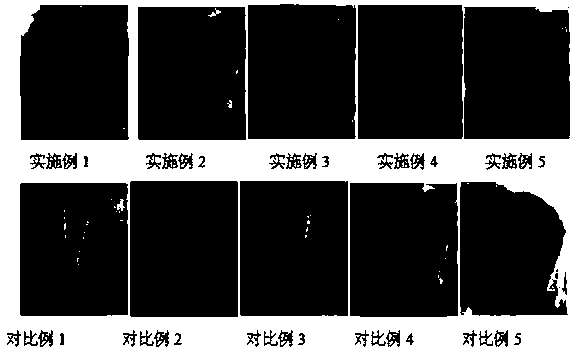

Method for preparing berry crisp chips

The invention discloses a method for preparing berry crisp chips. Berries are cleaned and sliced, then treated through the combination of ultra-high pressure and ultrasound after cryogenic treatment,and finally placed into a vacuum freeze dryer to perform drying. Ultra-high pressure and ultrasound combined treatment can be performed on the berries after the cryogenic treatment, then pre freezingcan be performed, and finally the berries can be put into the vacuum freeze dryer to perform drying so that berry crisp chips can be prepared, and therefore, the color of the berries can be improved,the flavor of the berries can be promoted to release, the time of vacuum freeze-drying can be shortened, drying efficiency can be enhanced, and energy consumption can be saved.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

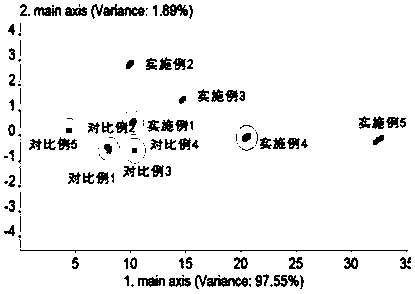

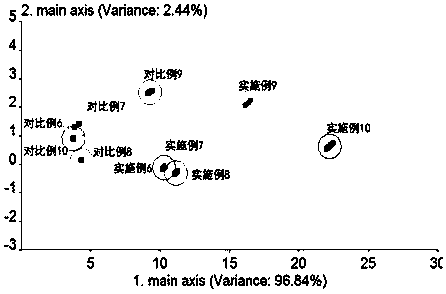

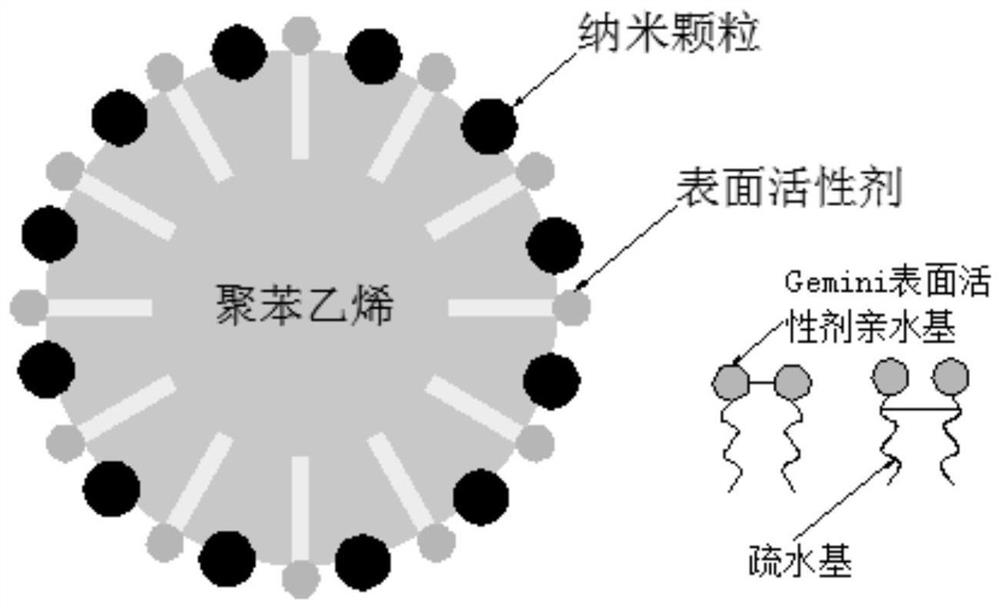

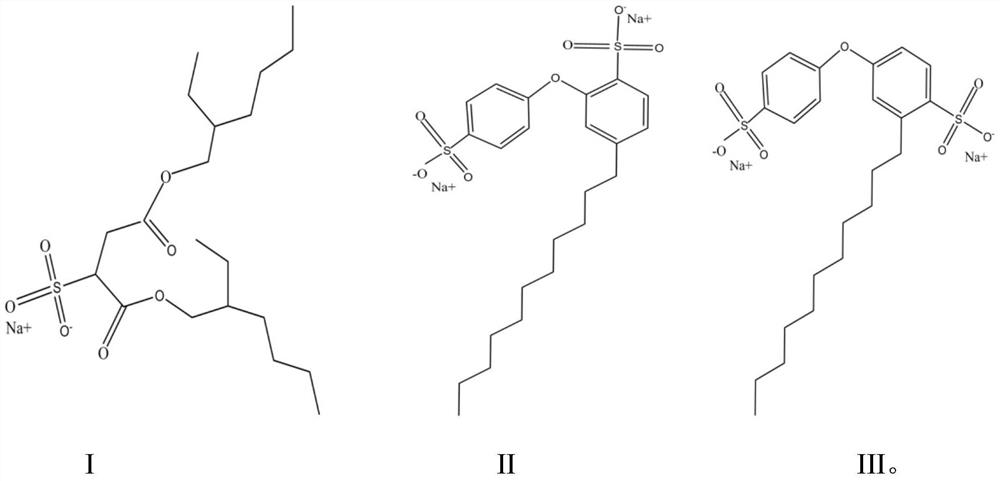

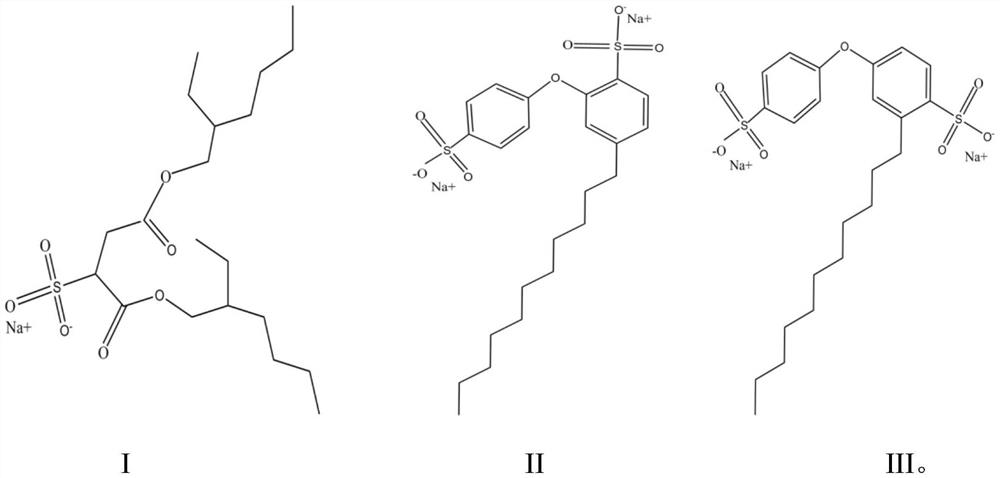

Gas hydrate accelerant based on nanoparticles and Gemini surfactant and application of accelerant

ActiveCN112940679AHelp passImprove thermal conductivityOther chemical processesGaseous fuelsPolymeric surfaceActive agent

The invention discloses a gas hydrate accelerant based on nanoparticles and a Gemini surfactant and application of the gas hydrate accelerant. According to the gas hydrate accelerant based on nanoparticles and a Gemini surfactant, the gas hydrate accelerant is formed by immobilizing nano Fe3O4 and an emulsifier on the surface of polystyrene based on emulsion polymerization reaction under an anaerobic operation condition by taking styrene as a monomer, deionized water as a solvent, peroxide as an initiator and the Gemini surfactant as the emulsifier. According to the gas hydrate accelerant provided by the invention, the Gemini surfactant and the nano Fe3O4 are wrapped on the surface of the polystyrene sphere, so that the heat and mass transfer rate can be improved, and the gas storage capacity cannot be reduced due to the fact that the Fe3O4 immobilized on the surface of a polymer occupies the position originally belonging to a single-chain surfactant SDS.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

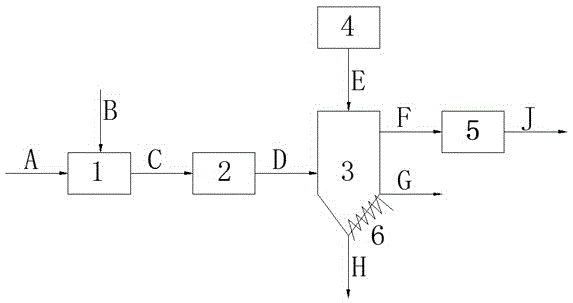

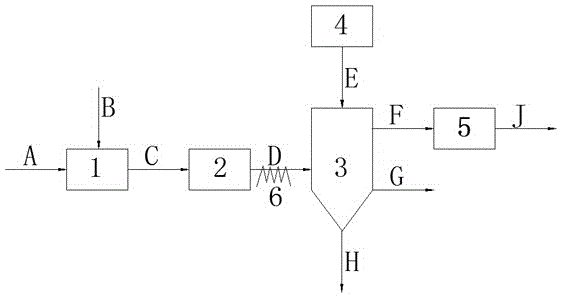

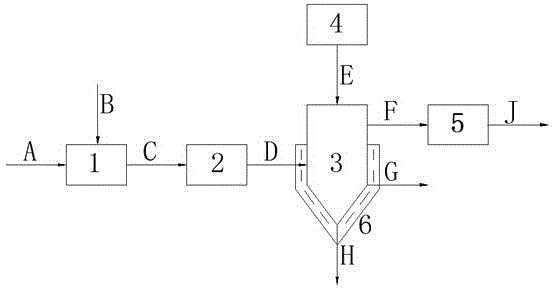

Biomass micro powder atomizing pyrolysis system and method

InactiveCN105038859AAchieve direct pyrolysisLow investment costGranular/pulverulent flues gasificationMetallurgyHigh energy

The invention discloses a biomass micro powder atomizing pyrolysis system and a biomass micro powder atomizing pyrolysis method. The biomass micro powder atomizing pyrolysis system comprises a Venturi, a preheater, a pyrolysis furnace and a fuel gas purifying device which are sequentially connected, wherein the inlet of the pyrolysis furnace is connected with an atomizer; and the pyrolysis furnace is provided with a heater. The biomass micro powder atomizing pyrolysis system can realize direct pyrolysis on biomass micro powder; a drying process with high energy consumption is not required; equipment investment and operation cost of the process are greatly reduced; and economical efficiency of the process is improved.

Owner:NANJING UNIV OF TECH

Continuous fuming production process

The invention discloses a continuous fuming production process. The process comprises one or more functional molten pools to form a continuous fuming furnace, the continuous fuming furnace is used forfuming production; the structure of the functional molten pools is similar to each other, the slag lines depth of the molten pools is more than 1.0 m, slag-immersed burners are arranged at the periphery of the side wall of the function molten pools, nozzles are located below the slag lines, the molten-state or cold-state-containing metallurgical material is directly added or added after being pretreated into the functional molten pools, the atmosphere in the molten pools and the metallurgical chemical reaction process are controlled through the combustion of the slag-immersed burners and strong stirring action, the materials are heated, melted, vulcanized, oxidized, reduced and fumed, in the fuming furnace, valuable metals are discharged from the melt body along with flue gas to form smoke dust and then enter a waste heat recovery and dust collection system, waste heat is recycled by the waste heat boiler, and enrichment and recovery of various valuable metals in the materials are realized through dust collecting. According to the continuous fuming production process, the production efficiency is improved, the production environment is improved, the labor intensity is reduced, andthe economic benefit is very remarkable.

Owner:CENT SOUTH UNIV

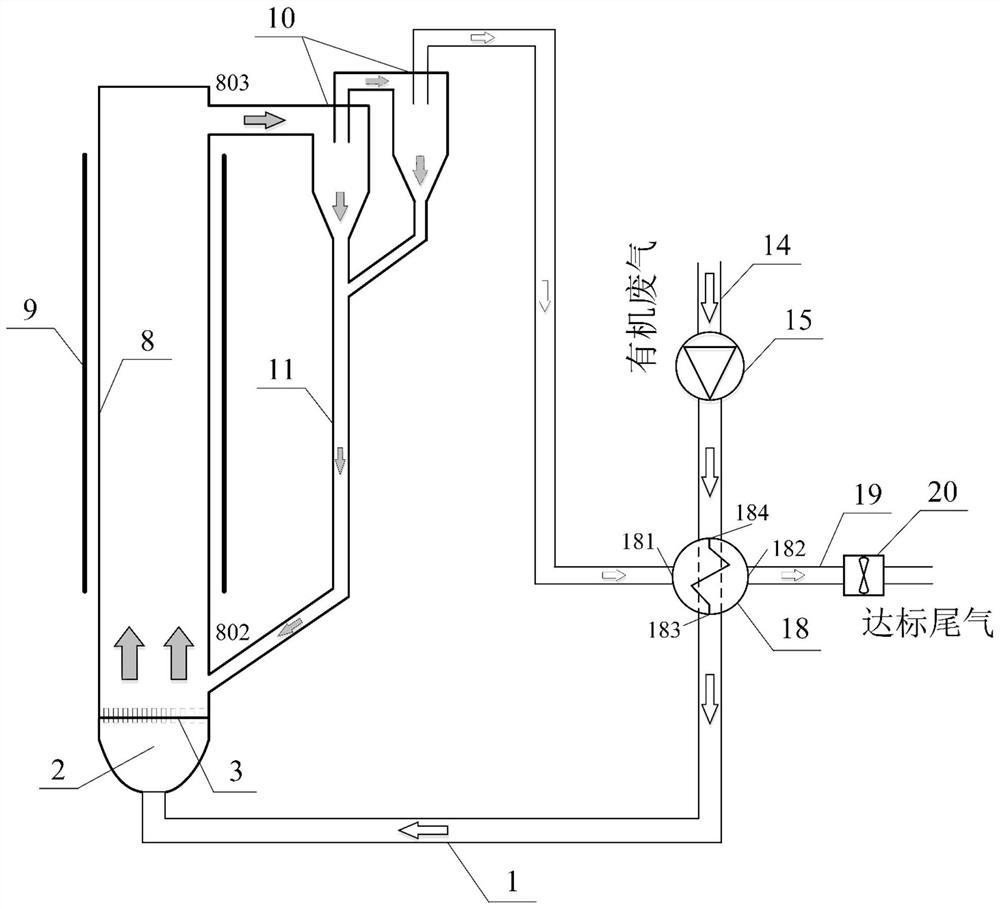

Circulating fluidized bed catalytic combustion system for treating organic waste gas

PendingCN111735071AReduce consumptionWide concentration rangeIncinerator apparatusFluidized bedExhaust fumes

The invention discloses a circulating fluidized bed catalytic combustion system for treating organic waste gas, and belongs to the field of environmental protection. The system comprises a circulatingfluidized bed catalytic combustion furnace, a heat exchanger (18) and an electric heating component (9); the circulating fluidized bed catalytic combustion furnace comprises a fluidized air chamber (2), an air distribution plate (3) and a riser (8); the fluidized air chamber (2) is connected with an organic waste gas header pipe (14) provided with a fluidized air blower (15) through a riser air inlet header pipe (1); an upper discharging opening (803) of the riser (8) with the electric heating component (9) distributed around is connected with a feeding opening of a separator (10); a discharging opening of the separator (10) is connected with a feeding opening of a dip-leg (11); a discharging opening of the dip-leg (11) is connected with a riser return pipe (802); and an air exhausting opening of the separator (10) is connected with the heat exchanger (18) through a pipeline. The system is high in removal rate and high in heat utilization rate and can run continuously and stably for along time.

Owner:JIANGSU NANFANG COATING & ENVIRONMENT PROTECTION EQUIP +1

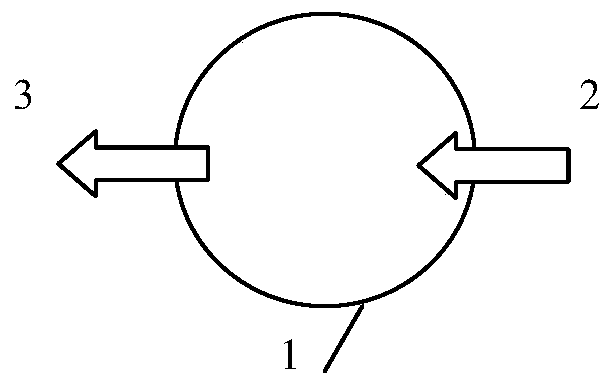

Pulse type lift pipe regenerator

InactiveCN101480625AIncrease heat and mass transfer rateHigh char strengthCatalyst regeneration/reactivationFluidized bedChemical engineering

The invention provides a pulse-type lift pipe regenerator which belongs to an improvement on a fluidized bed regenerator structure. The pulse-type lift pipe regenerator mainly comprises a regenerating lift pipe, a big pipe, a small pipe, a regenerating agent inlet, a lift pipe inlet, a lift pipe outlet, and the like. The invention is mainly characterized in that the pipe diameter of the lift pipe regenerator reduces and expands alternately to form the pulse-type lift pipe combining the big pipe and the small pipe.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation method of sic foam, sic foam monolithic catalyst for methane catalytic combustion and preparation method thereof

ActiveCN108686714BHigh strengthSmall thermal expansionCatalyst carriersCarbon compoundsPtru catalystCatalytic combustion

The invention discloses a preparation method of SiC foam, a SiC foam monolith catalyst for methane catalytic combustion and a preparation method thereof, wherein the SiC foam is placed in a polysilane solution by glassy carbon foam, and is impregnated, dried, and reacted at a high temperature be made of. The SiC foam monolithic catalyst comprises SiC foam on which a transition layer is deposited, on which a second carrier is deposited and loaded with noble metals. Its preparation method includes depositing transition layer and second carrier, heat treatment and loading noble metal. The preparation method of the SiC foam of the present invention has the advantages of simple preparation and low cost, and the obtained SiC foam is a very promising catalyst carrier. The SiC foam monolithic catalyst of the present invention has the advantages of high catalytic activity, high strength, high temperature resistance, high heat and mass transfer rate, and long life, and is a promising new methane catalyst. The preparation method has the advantages of simple process and low cost. , Low requirements on equipment, safe operation and so on.

Owner:NAT UNIV OF DEFENSE TECH

Energy-saving flash suspension kiln system

The invention discloses an energy-saving flash suspension kiln system. The systm comprises a first feeding point, a kiln and a first gas-solid separator, the kiln comprises a first feeding port, a second feeding port, a damping section, a firing section, a reflecting section and a clinker outlet, and the damping section, the firing section and the reflecting section are sequentially arranged from the first feeding port to the clinker outlet; the damping section comprises a damping unit and a flow channel, raw materials penetrate through the damping section from the flow channel, the firing section is communicated with the second feeding port, the first feeding point is connected with the first feeding port, the first gas-solid separator comprises a first gas inlet, a first gas outlet and a first discharging port; the first air inlet is connected with the first feeding port, and the first discharging port is connected with the second feeding port. The energy-saving flash suspension kiln system provided by the invention has the characteristics of low energy consumption, low pollution, stable product quality, simple structure and low one-time investment.

Owner:辽宁荣邦科技有限公司

Preparation method for composite phase-change energy accumulation material micro mist

InactiveCN101368087BDifficult to disperseGood dispersionHeat-exchange elementsInlet temperatureEmulsion

The invention provides a method for preparing composite phase transformation energy storage material miropowder. In the preparation method, an organic phase transformation material, sorbitan oleate 80 and polyoxyethylene sorbitan monooleate 80 are mixed; the mixture is added to water solution containing polyvinyl alcohol, and an additive in alkali metal salt series is added; the mixture is stirred at 40 to 95 DEG C so that the phase transformation material is uniformly dispersed to form emulsion; ethyl orthosilicate and an acidic catalyzer are added to the emulsion; the mixture of the emulsion, the ethyl orthosilicate and the catalyzer react for 3 to 12 hours in a water bath and are aged at room temperature, thus manufacturing paste containing 3 to 30 percent of solid by weight; the pasteis added to a spray drying tower through a peristaltic pump rotating at 0 to 70rpm, and is sprayed and dried with the inlet temperature from 160 to 240 DEG C and the outlet temperature from 50 to 100DEG C. As the spray-dry method is adopted, the problem that the phase transformation energy storage material microcapsule miropowder is dispersed difficultly during the subsequent drying process is successfully solved; the product quality is ensured; the production cycle is shortened; and the production efficiency is improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

A kind of compound drying preparation method of reduced viscosity fruit embryo

ActiveCN104489535BWater evaporates quicklyIncrease heat and mass transfer rateFood dryingFruits/vegetable preservation by dehydrationFruit cakeSnack food

The invention discloses a compound-drying preparation method of a viscosity-reduced semi-finished fruit. The compound-drying preparation method disclosed by the invention mainly comprises the following steps of: removing shells and kernels of fruits, carrying out pulse vacuum micro-wave drying with the help of hot-air drying to obtain a semi-finished fruit having proper water content, and then, carrying out rehydration penetration drying of the semi-finished fruit to obtain the viscosity-reduced semi-finished fruit. The compound-drying preparation method disclosed by the invention is characterized in that intermittent drying is adopted in the pulse micro-wave vacuum drying stage, the semi-finished fruit is rapid in mass transfer and uniform in heat transfer, and the drying time is shortened; and the penetrated and dried semi-finished fruit in the later stage has better machining properties, and the requirements of reducing the viscosity and mechanically cutting into granules of traditional dried semi-finished fruits of tropical and subtropical fruits, such as a large number of litchi and longan are realized by adopting compound-drying. Fruit granules are widely added into fruit cakes and natural healthy snack foods, furthermore, a lot of semi-finished fruits can be mechanically processed, and thus, manpower is saved.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

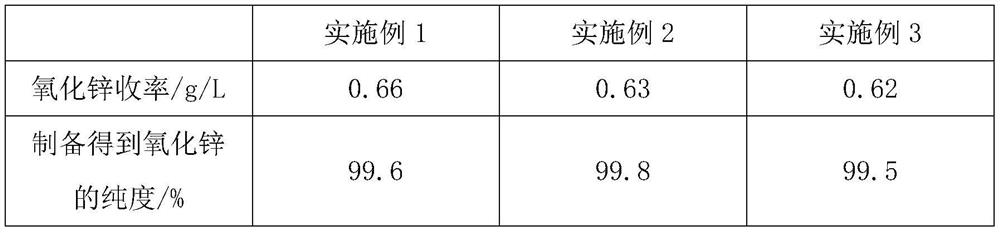

Rapid recycling method of zinc-containing pickling waste liquid

InactiveCN112573559AIncrease heat and mass transfer rateEvenly heatedZinc oxides/hydroxidesChemistryProcess engineering

The invention relates to the technical field of pickling waste liquid treatment, in particular to a rapid recycling method of zinc-containing pickling waste liquid. The method comprises the followingsteps: injecting the zinc-containing pickling waste liquid into a sedimentation tank, slowly injecting a saturated ammonium bicarbonate solution until the pH value of the system is 6.2-6.6, standing and settling at 30-35 DEG C for 15-20 hours, filtering the lower precipitate, adding the filter cake into a washing tank, washing with a sodium hydroxide solution, and drying, and obtaining a basic zinc carbonate crude product; enabling the ball-milled basic zinc carbonate crude product to enter a suspension calcining device under the driving of hot air, performing primary suspension preheating to300-350 DEG C, performing secondary suspension heating to 550-600 DEG C, finally heating to 800-850 DEG C, performing suspension calcining, collecting zinc oxide obtained by suspension calcining through a cyclone collector, enabling separated hot air to enter a primary suspension process for recycling. High-purity zinc oxide is obtained by the method so that waste is turned into wealth; the methodis low in cost, high in efficiency, high in product quality and environmentally friendly, and a good technical scheme is provided for treating the zinc-containing pickling waste liquid in the iron and steel industry.

Owner:桃江县德聚人和中小企业公共服务平台有限公司

A device for continuously separating methane in mixed coalbed methane by using hydrate

ActiveCN107903969BIncrease profitIncrease production rateGaseous fuelsThermodynamicsHydrate decomposition

The invention relates to the industrial field of petroleum natural gases and in particular to a device and a method for continuously separating methane in a coalbed methane-air mixture by using a hydrate. The device comprises one twisted strip hydrate preparation device and two laval hydrate preparation devices, wherein the twisted strip hydrate preparation device is used for improving heat and mass transfer through a twisted strip; the laval hydrate preparation devices are used for increasing supercooling degrees by using laval ejection tubes; two three-phase separation devices are arranged behind the twisted strip hydrate preparation device; one three-phase separation device is at a storage state; another one three-phase separation device is at an hydrate decomposition state; and the twostates can be transformed into each other. Through spiral flows generated by the twisted strip, the hydrate can be fed into the three-phase separation devices in a pulp manner without being blocked in the twisted strip hydrate preparation device; a coalbed gas which is not completely reacted is fed into the laval hydrate preparation devices, then methane hydrate generation conditions are met, andmethane in the coalbed gas can be further extracted; the two laval hydrate preparation devices at a preparation state and a decomposition state are available, and through transforming of the two states, an industrial requirement of continuous hydrate preparation is met.

Owner:CHANGZHOU UNIV

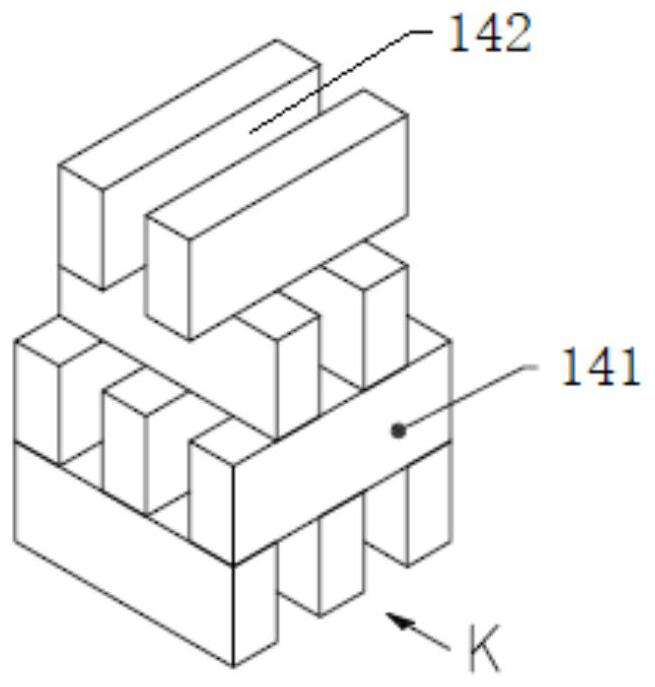

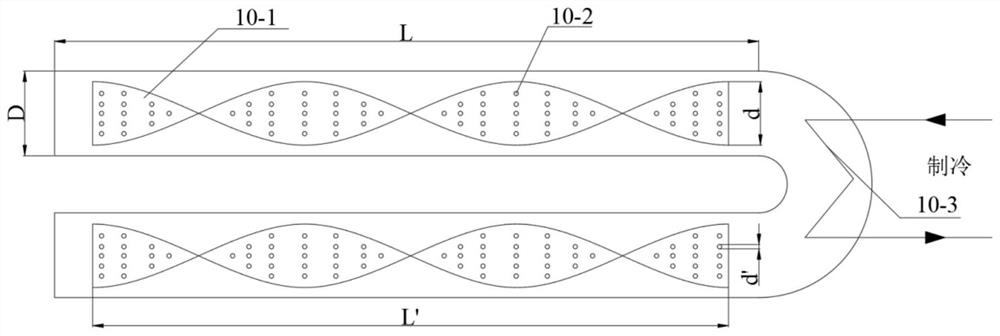

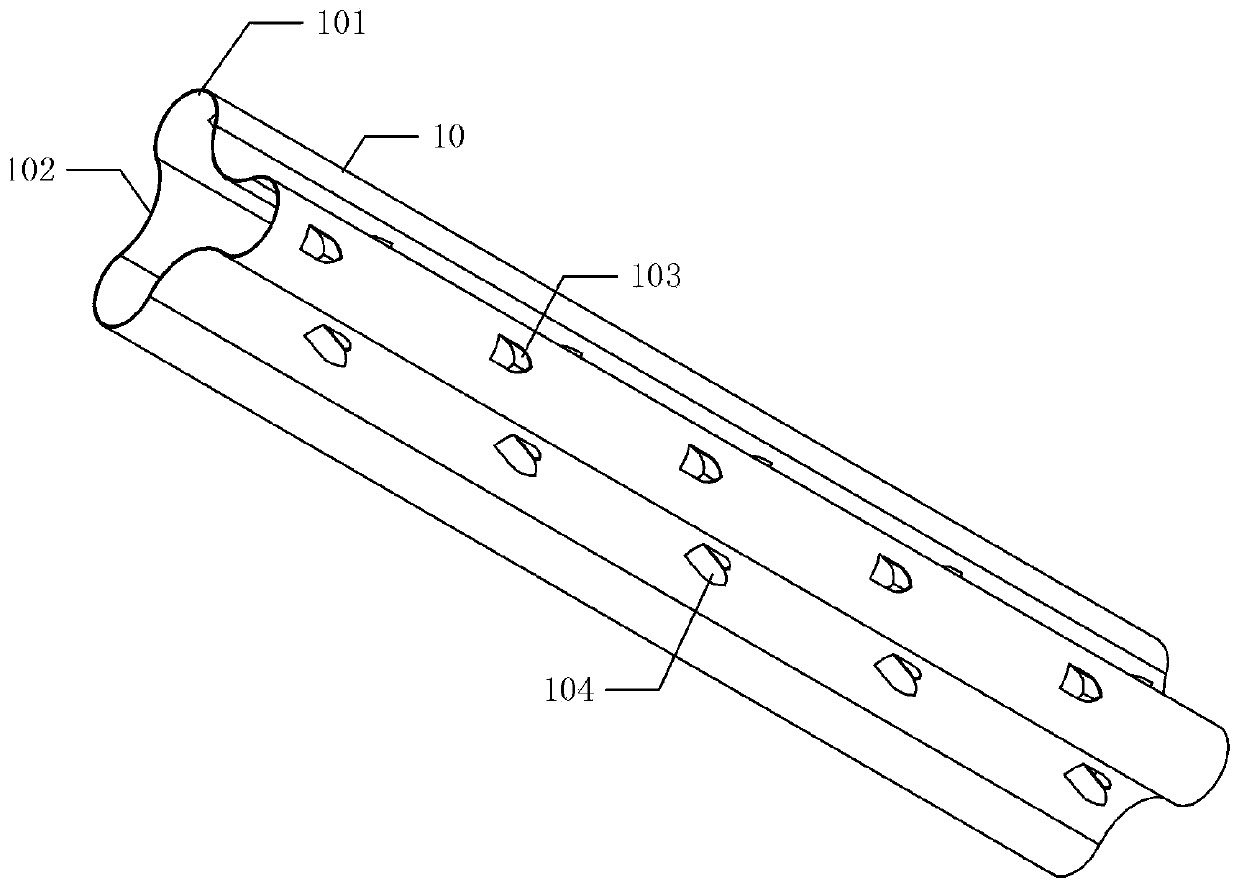

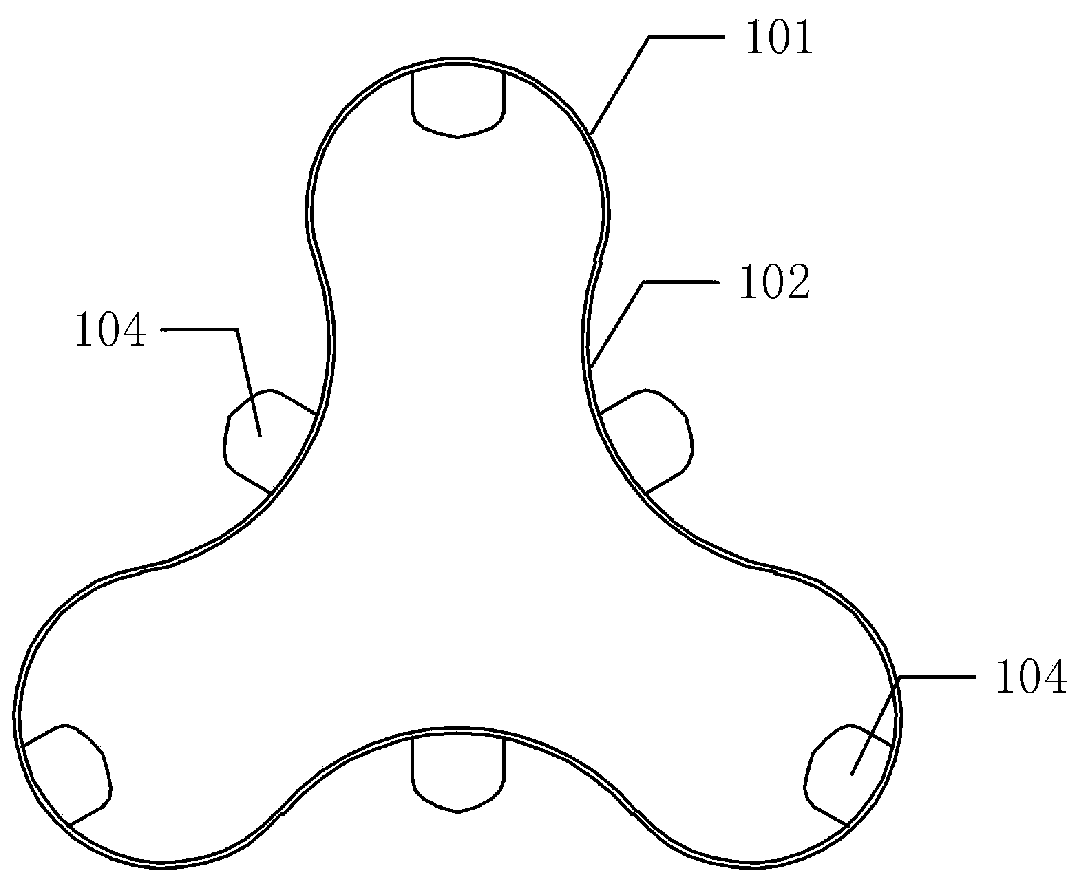

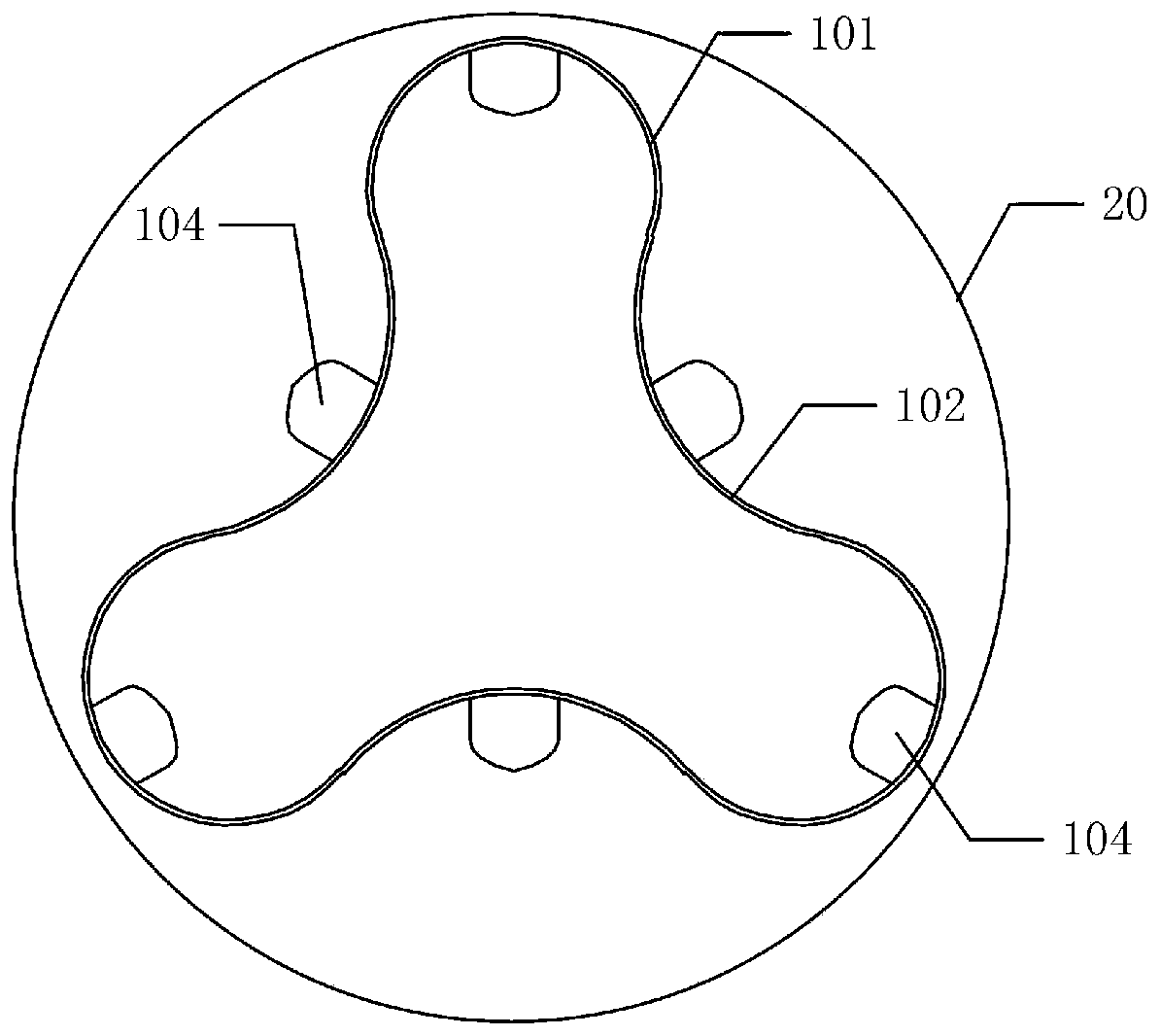

Reinforced heat and mass transfer pipe insert and heat and mass transfer pipe

PendingCN111595190ABreak laminar flowHigh heat and mass transfer coefficientTubular elementsEngineeringMechanical engineering

The invention provides a reinforced heat and mass transfer pipe insert and a heat and mass transfer pipe. The insert is a tubular body; the tube wall of the tubular body is composed of a plurality ofalternately arranged near-wall flow guide portions and a central flow guide portion; each near-wall guide portion is an outward-protruding structure arranged in the axial direction of the tubular body; the central flow guide part is an inward-recessed structure arranged in the axial direction of the tubular body; the near-wall flow guide portions and the central flow guide portion are each uniformly provided with flow disturbing holes; and each flow disturbing hole is provided with a flow disturbing plate extending into or out of the tube wall of the tubular body. According to the reinforced heat and mass transfer pipe insert provided by the invention, the near-wall flow guide portions and the central flow guide portion are each provided with the flow disturbing holes and the flow disturbing plate; the near-wall flow guide portions are used for guiding the fluid at the near-wall position of the heat and mass transfer pipe to the center; the center flow guide portion is used for guidingthe fluid from the center of the heat and mass transfer pipe to the near-wall position to generate radial flow disturbance, thereby breaking the laminar flow state inside the heat and mass transfer pipe and improving the heat and mass transfer coefficient.

Owner:TIANJIN AOZHAN XINGDA TECH

A vacuum vapor compression distillation sea water desalination device

InactiveCN103387270BIncrease water production rateIncrease heat and mass transfer rateGeneral water supply conservationSeawater treatmentWater desalinationSteam condensation

The present invention relates to a vacuum vapor compression distillation sea water desalination device comprising: a sea water pump, a seal chamber, a vacuum evaporation chamber and a vacuum pump and other components. In operation, a drive shaft drives the vacuum evaporation chamber filled with fresh water to rotate, after the formation of a vacuum area without water, sea water is fed in, and at the same time working vapor is fed in a vapor pipe coil, heat transfer between the vapor in the vapor pipe coil and the outside sea water enable the condensation of the vapor to obtain fresh water, while the sea water volatilizes to form primary vapor; and after temperature and pressure rise via a impeller, the primary vapor is fed in the vapor pipe coil as the working vapor for continuous vapor compression distillation to achieve sea water desalination. According to the device of the invention, centrifugal force is employed to replace the gravity to obtain a vacuum environment, operations are all in room temperature, no external heat source is required, and circular energy supply is achieved by the utilization of latent heat of the vapor; the water production rate and the energy utilization rate of the system are high; and the device has advantages of a simple process, a compact structure, little corrosion and scaling, etc.

Owner:HAINAN UNIV +1

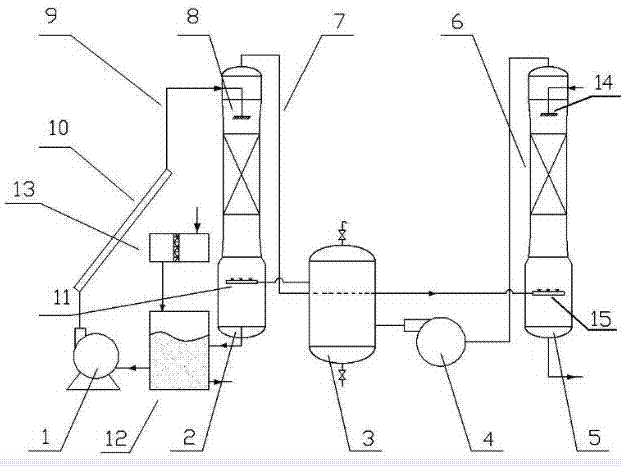

A humidifying-dehumidifying seawater or brackish water desalination device and method

InactiveCN105036220BIncrease heat and mass transfer rateLow vaporization temperatureGeneral water supply conservationSeawater treatmentWater desalinationWater vapor

The present invention belongs to a humidification-dehumidification desalination method and apparatus for sea water or brackish water, and the apparatus includes pretreatment system and a humidification-dehumidification system. The pretreated seawater or brackish water is introduced into a storage tank, preheated by a heater, pumped into a humidification tower; and then the seawater or brackish water passes through an overhead liquid distributor and directly contacts with the bottom-up carrier gas flowing through a packed column, so as to humidify the carrier gas; and the carrier gas with high humidity is introduced to dehumidification tower bottom via a pipeline, and direct contacts with the top-down cooling water, and the water vapor is condensed and discharged with cooling water, so as to obtain fresh water. The method uses the characteristics of large specific surface area and small resistance of the filler, realizes gas-liquid interphase faster heat and mass transfer, and is applicable to sea island, desert and thermal power plants. Compared with the prior desalination technology, the apparatus has the characteristics of simple equipment, easy operation, easy treatment and cleaning, small investment, and easy operation and maintenance.

Owner:ZHEJIANG UNIV

A jet mixer

InactiveCN102954047BSolve the problem of low ejection efficiencyReduce weightFlow mixersTransportation and packagingEngineeringStreamflow

Owner:韩铁夫

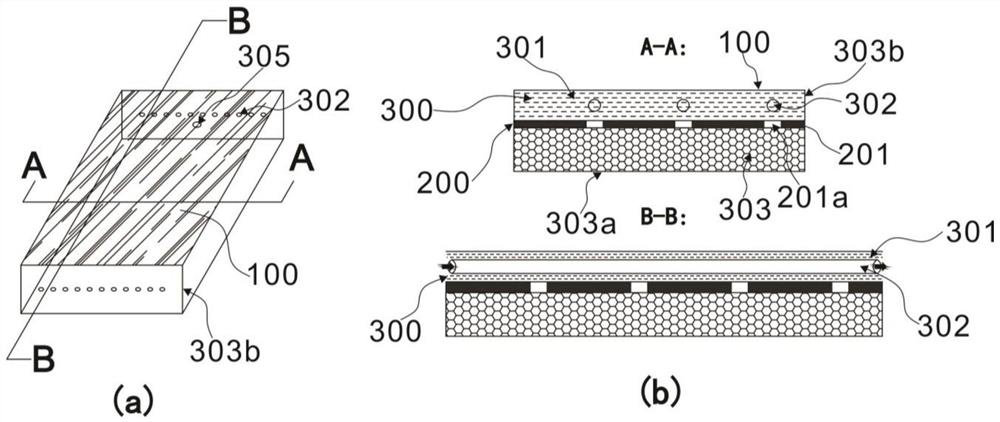

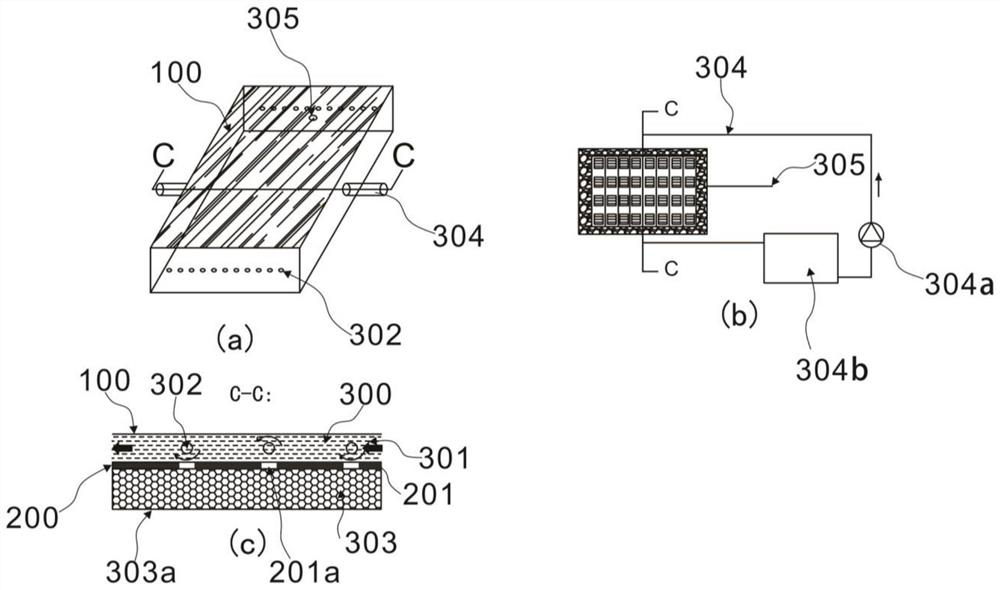

A nanofluidic microchannel photovoltaic photothermal integrated evaporator/collector

ActiveCN112594948BSmall sizeReduce occlusionSolar heating energyPV power plantsGlass coverThermal insulation

The invention discloses a nano-fluid micro-channel photovoltaic photothermal integrated evaporator / heat collector, which is mainly composed of a glass cover plate, a nano-fluid and its flow channel, a micro channel, a photovoltaic cell, a thermal insulation material layer and a frame. The invention combines a microchannel with a nanofluid-PV / T heat collector based on spectral frequency division; the microchannel is immersed in the nanofluid and placed in the middle of two photovoltaic cells, which can simplify the heat transfer thermal resistance of the heat collector. structure and guarantee low occlusion. The size of the microchannel and the nanofluid flow channel are matched, the heat transfer rate is high and the specific surface area is large, which can ensure the heat transfer effect in the flow channel regardless of natural circulation or forced circulation. At the same time, it can be used as a heat collector (single-phase working medium in the microchannel) and evaporator (two-phase working medium in the microchannel) at the same time according to application requirements.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

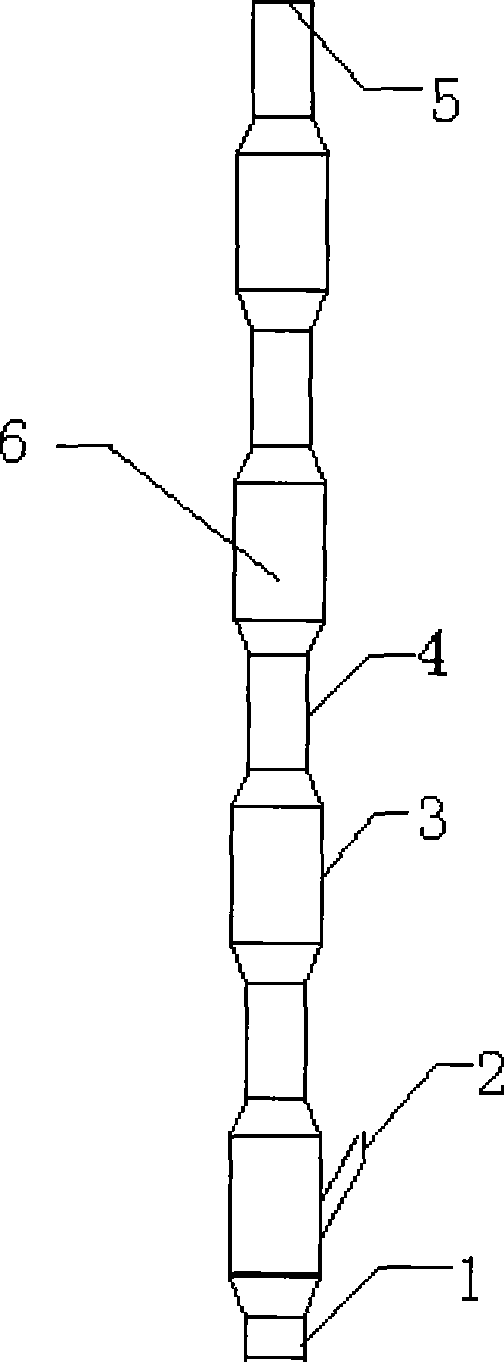

Novel pulse biomass pyrolysis reactor and pyrolysis technology

InactiveCN108102675AShort gas phase residence timeAvoid secondary crackingDirect heating destructive distillationBiofuelsParticle flowThermodynamics

The invention provides a novel pulse biomass pyrolysis reactor and a pyrolysis technology. The reactor comprises a long barrel-shaped reaction section, wherein a biomass inlet and a lifting gas inletare formed in the inlet of the reaction section; the reaction section comprises a plurality of contraction sections and expansion sections which are alternately connected with one another; a pluralityof heat energy nozzles are arranged on the reaction section. The pulse biomass pyrolysis reactor with the novel structure has the advantages that the pipe diameter is alternately reduced or enlargedduring reaction operation, airflow and particles flow at inequable speed, and the relative speed between airflow and particles and the heat transfer area are large, so that the rate of heat transfer and mass transfer is enhanced. In addition, the speed of airflow in an expansion pipe is greatly reduced, so that the reaction time is correspondingly increased. Through the control of energy control reaction temperature of material feeding and the heat energy nozzles, the characteristic of stable product yield is achieved.

Owner:山东泰然生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com