Rapid recycling method of zinc-containing pickling waste liquid

A technology for the recycling of pickling waste liquid, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of environmental pollution of zinc-containing pickling waste liquid, and achieve the effects of low cost, uniform heating and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

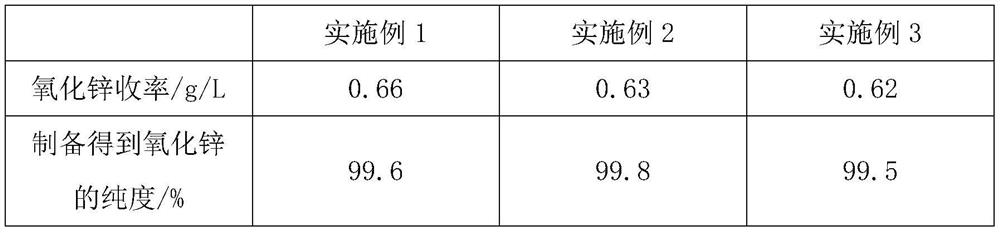

Embodiment 1

[0021] A rapid recycling method for zinc-containing pickling waste:

[0022] Zn 2+ The zinc-containing pickling waste liquid with a substance concentration ≥ 0.01mol / L is injected into the sedimentation tank through the delivery pipe, and the saturated ammonium bicarbonate solution is slowly injected until the pH of the system is 6.2 to 6.6, and the injection of the saturated ammonium bicarbonate solution is stopped. Settle at 35°C for 18 hours, absorb the supernatant, filter the sediment below, add the filter cake to the washing tank, wash with 10% sodium hydroxide solution, filter, wash the filter cake with water, and put it in an oven at 90°C Dry in medium for 15 hours to obtain the crude product of basic zinc carbonate; add the crude product of basic zinc carbonate to a ball mill tank, adopt a ball-to-material ratio of 10:1, anhydrous ethanol and polyethylene glycol 400 with a volume ratio of 10:1 as a composite dispersant , the weight of the composite dispersant is 12% o...

Embodiment 2

[0024] A rapid recycling method for zinc-containing pickling waste:

[0025] Zn 2+ The zinc-containing pickling waste liquid with a substance concentration ≥ 0.01mol / L is injected into the sedimentation tank through the delivery pipe, and the saturated ammonium bicarbonate solution is slowly injected until the pH of the system is 6.2 to 6.6, and the injection of the saturated ammonium bicarbonate solution is stopped. Settle at 30°C for 20 hours, absorb the supernatant, filter the sediment below, put the filter cake into the washing tank, wash with 10% sodium hydroxide solution, filter, wash the filter cake with water, and put it in an oven at 85°C Dry in medium for 15 hours to obtain the crude product of basic zinc carbonate; add the crude product of basic zinc carbonate to a ball mill tank, use anhydrous ethanol and polyethylene glycol 400 with a ball-to-material ratio of 12:1, and a volume ratio of 5:1 as a composite dispersant , the weight of the composite dispersant is 10...

Embodiment 3

[0027] A rapid recycling method for zinc-containing pickling waste:

[0028] Zn 2+ The zinc-containing pickling waste liquid with a substance concentration ≥ 0.01mol / L is injected into the sedimentation tank through the delivery pipe, and the saturated ammonium bicarbonate solution is slowly injected until the pH of the system is 6.2 to 6.6, and the injection of the saturated ammonium bicarbonate solution is stopped. Settle at 30°C for 15 hours, absorb the supernatant, filter the sediment below, add the filter cake to the washing tank, wash with 10% sodium hydroxide solution, filter, wash the filter cake with water, and put it in an oven at 80°C Dry in medium for 10 hours to obtain the crude product of basic zinc carbonate; add the crude product of basic zinc carbonate to a ball mill tank, use anhydrous ethanol and polyethylene glycol 400 with a ball-to-material ratio of 10:1, and a volume ratio of 5:1 as a composite dispersant , the weight of the composite dispersant is 10% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com