Novel pulse biomass pyrolysis reactor and pyrolysis technology

A biomass pyrolysis and reactor technology, which is used in biofuels, petroleum industry, direct heating and dry distillation, etc., can solve the problems of poor development prospects, short solid phase retention period, and fast heating speed, and achieve enhanced heat transfer. Mass rate, short gas phase residence time, effect of increasing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

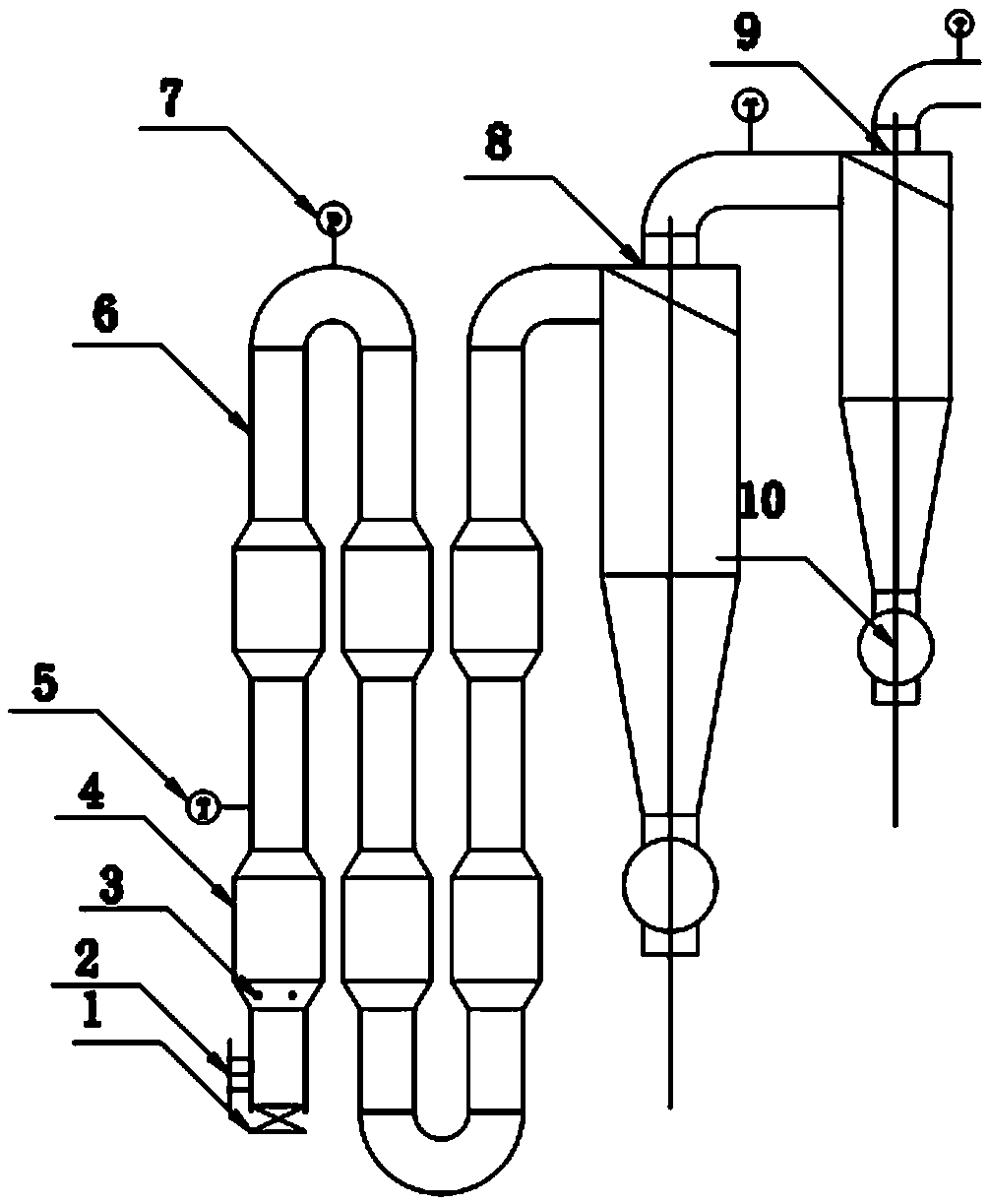

[0030] see figure 1 , a new type of pulse biomass pyrolysis reactor, the reactor includes a long cylindrical reaction section that is arranged in a circuitous manner, and the inlet of the reaction section is provided with a biomass feed port, namely a material inlet 2 and a lifting gas inlet (a control device is installed on it) Valve 1), the outlet of the reaction section is connected to the cyclone separator; the cyclone separator is two stages connected in series, that is, the first-stage cyclone separator 8 and the second-stage cyclone separator 9, and the bottom of each stage cyclone separator is installed The air locker 10; the reaction section is composed of multiple alternately connected contraction sections 6 and expansion sections 4; the inlet section of the reaction section is provided with a plurality of heat nozzles 3; the middle section of the reaction section is provided with a thermometer 5 and a pressure gauge 7.

Embodiment 2

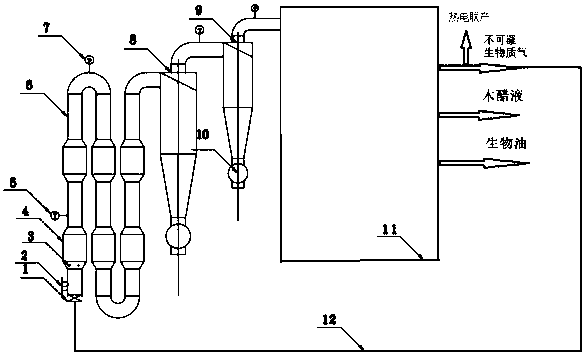

[0032] see figure 2 , a pyrolysis process based on the establishment of the novel pulse pyrolysis reactor of embodiment 1, comprising the steps of:

[0033] (1) Use biomass straw as raw material, crush it to a particle size of 1-5 mm, and then dry it to a biomass raw material with a relative moisture content of 8-12%;

[0034] (2) Use the non-condensable biomass gas produced by pyrolysis as the lifting gas to bring the biomass raw material into the reaction section, and at the same time input heat through the thermal energy nozzle for pyrolysis; And the product output needs to be isolated from the air, and the control system has a slight negative pressure of -700~-1500Pa;

[0035] (3) The products produced by pyrolysis are separated by solid, liquid and gas to obtain solid products, liquid products and non-condensable biomass gas; solid products include biochar, which is obtained through a secondary cyclone separator, and liquid products include bio-oil , wood vinegar, etc....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com