A jet mixer

A technology for ejectors and flow mixers, which is applied in the direction of fluid mixers, mixers, jet pumps, etc., and can solve the problem that high-efficiency injection mixers are not suitable, the axial size and weight of the ejector are large, and the installation and use are unfavorable etc. to solve the problems of low ejection efficiency, reduced length, weight and size, and shortened length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

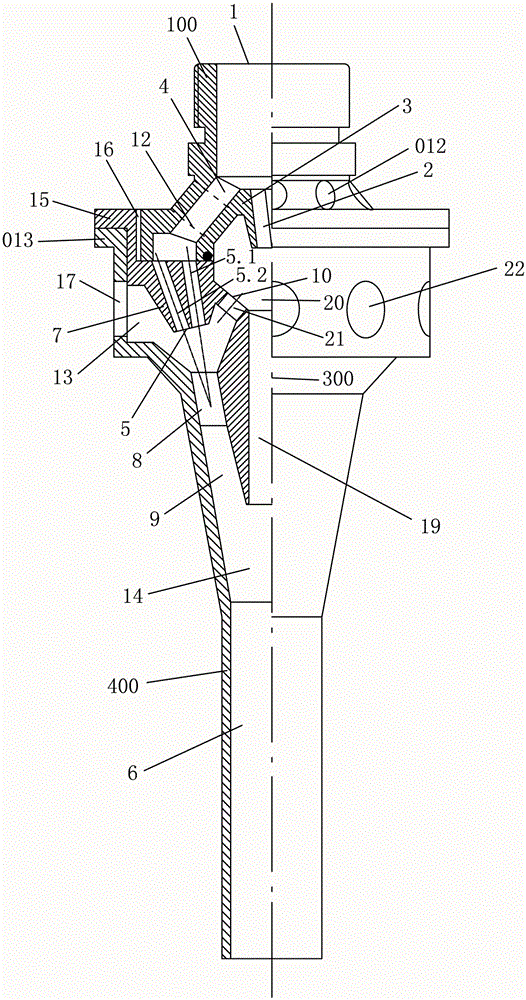

[0042] Example 1 see figure 1 ,

[0043] The injection mixer in this embodiment uses a main fluid to inject the secondary fluid from the porous upper port 012 of the secondary fluid and the porous side port 22 of the secondary fluid, and outputs the mixed fluid from the total mixing output pipe 6. device. The secondary fluid inlet / pipe and the main fluid inlet pipe are respectively arranged on the side of the inlet section of the ejector mixer and at both ends of the axis of the ejector mixer, which are respectively connected to the central ejector and the outer ring ejector; the central ejector The front part of the outer ring ejector and the outer ring ejector are concentrically fixed, and the middle and rear parts of the two are concentrically nested; the output port of the outer ring ejector is surrounded by the output nozzle of the central ejector, and they are directly connected to the main mixing chamber and the main ejector of the main ejector. Its total mixing pipe;...

Embodiment 2

[0050] Embodiment 2 see Figure 2-6

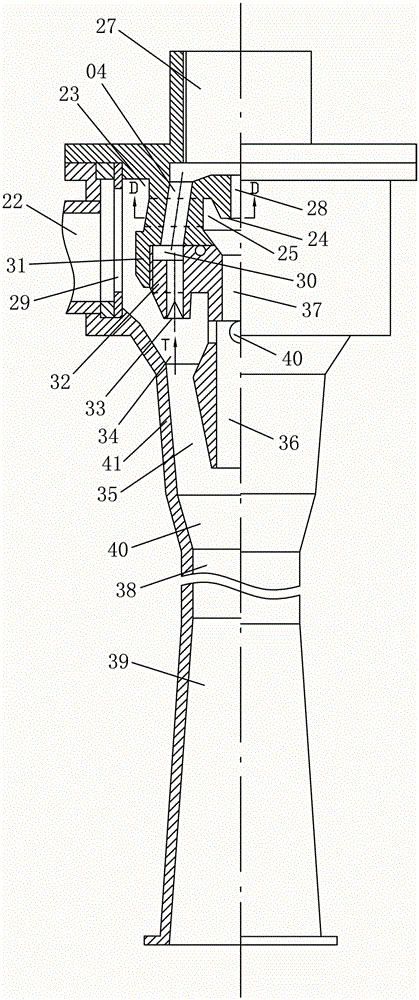

[0051] The jet mixer in this embodiment uses a primary fluid to inject a secondary fluid and outputs a mixed fluid. There is a central ejector and an outer ring ejector, the former is coaxially set in the latter, and both have the same main fluid inlet pipe and common total mixing output pipe. Its structure is roughly the same as the previous example. The same parts will not be described again, and the differences are as follows:

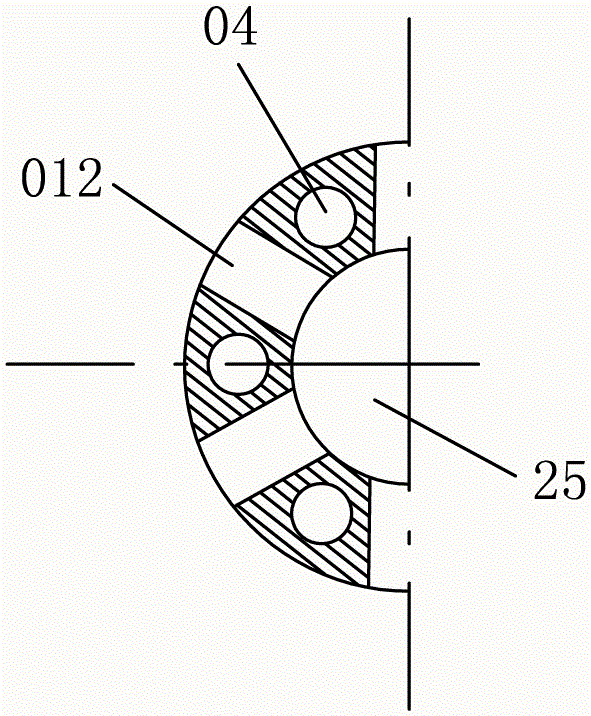

[0052] In this embodiment, the inner tube is in the shape of a flat umbrella, with a funnel-shaped central hole inside, and extends downwards into a central throat 37 and a central mixing tube 36 thereof; image 3 As shown, the central outlet hole of the main fluid inlet pipe 27 is provided with a central nozzle 24, and the lower part of the main fluid inlet pipe 27 is expanded into an annular flow distribution sleeve 31, and vertical porous main fluid passages are evenly distributed on the peripheral wall of...

Embodiment 3

[0059] Embodiment 3 see Figure 7 , 8 ,9

[0060] The injection mixer of this embodiment is also a kind of injection mixer that uses a main fluid to inject a secondary fluid and outputs a mixed fluid. It is coaxially set by the central injector and the outer ring injector. The two have a central main fluid inlet pipe and a common total mixing outlet pipe 53, and a common secondary fluid inlet pipe 42 is arranged horizontally on the side of the annular mixing chamber. This embodiment is basically the same as Embodiment 2, and the common place is no longer expressed, and the difference lies in:

[0061] In this implementation, only one secondary fluid inlet pipe is provided in the jet mixer, and the annular mixing chamber 43 is not provided with a uniform annular distribution sleeve. In order to improve the uniform supply of the secondary fluid and facilitate the injection mixing, the axis of the secondary fluid inlet pipe horizontally positioned on the side of the annular mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com