Dual ring ejector

An injector and ring-type technology, which is applied in the field of double-ring injectors, can solve the problems of simple function, lower injection coefficient or injection ratio, axial size of injector injector, large space occupation and weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

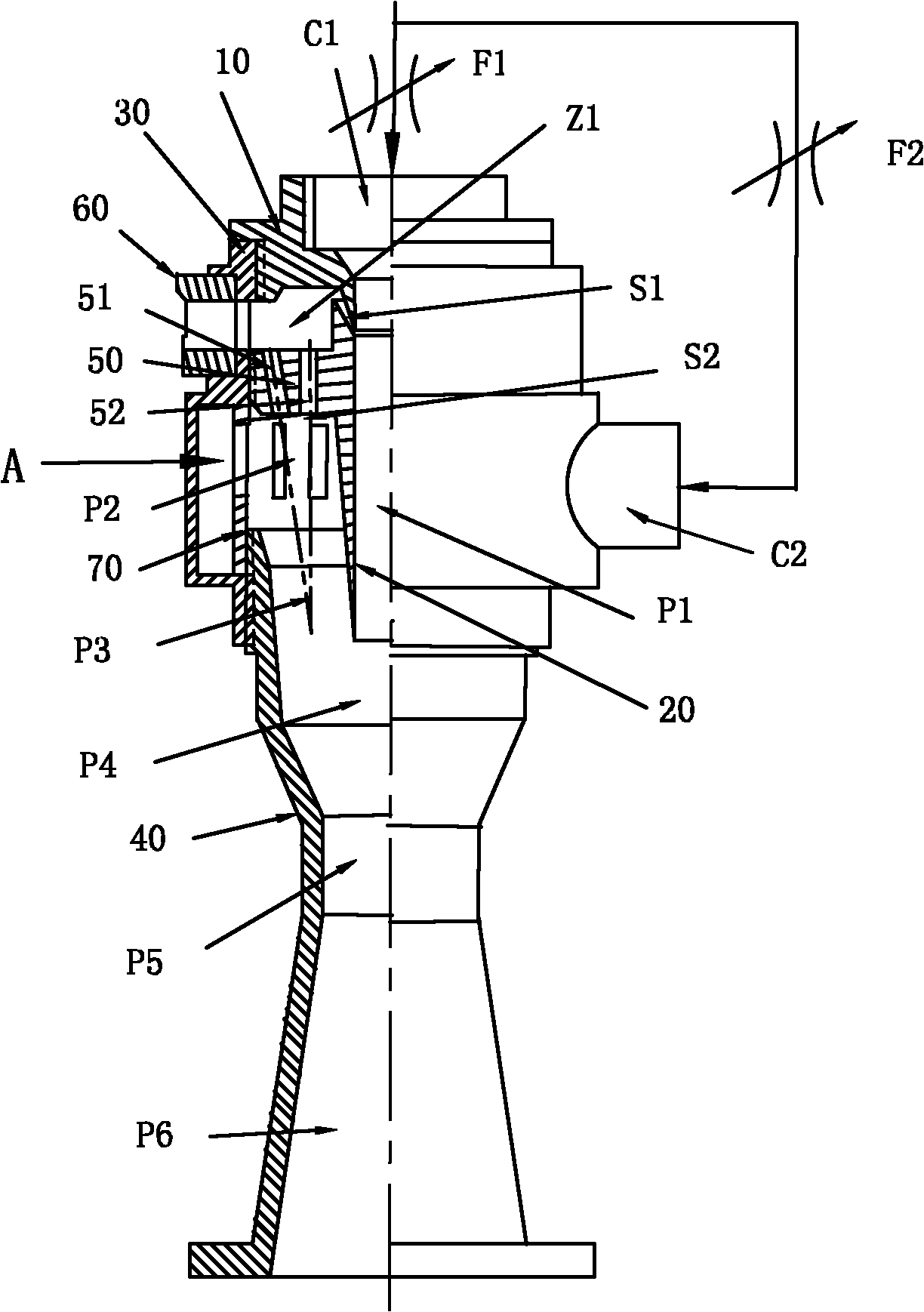

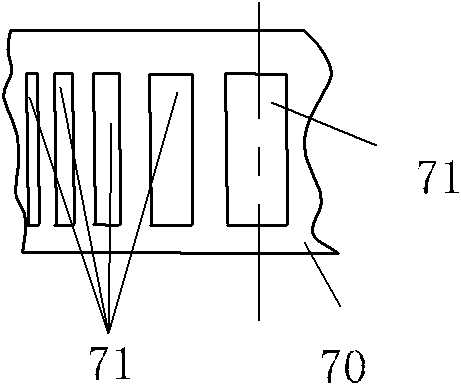

[0046] The first embodiment of the double-ring injector of the present invention is an injector that uses a primary fluid to guide two secondary fluids entering from two secondary fluid inlets, and outputs a mixed fluid. see figure 1 , the present embodiment is provided with an inner ring injector assembly and an outer ring injector assembly along the central axis, and the outer ring injector assembly is provided with a total mixing output pipe backward along the central axis. The inner ring injector assembly is coaxially fixed and sleeved in the outer ring injector assembly.

[0047] The inner ring injector assembly is provided with a central secondary fluid inlet sleeve 10 and an inner tube 20 , both of which are coaxial and the inner tube 20 is located at the outlet end of the central secondary fluid inlet sleeve 10 . The caliber of the inlet C1 of the central secondary fluid inlet sleeve 10 is larger than the outlet caliber, and the tapered mouth at the rear end of the ce...

Embodiment 2

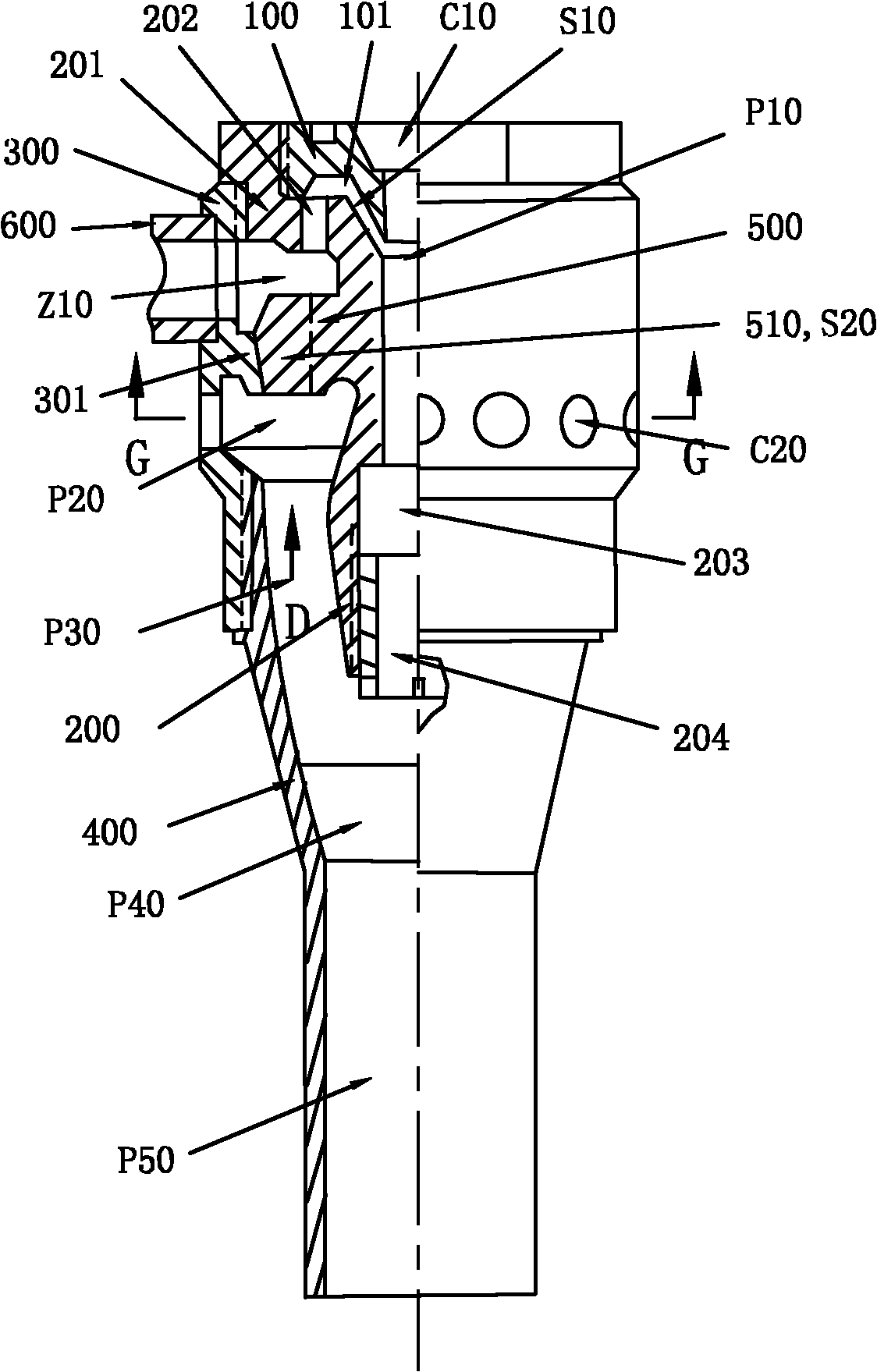

[0056] For a second embodiment of the double-ring injector of the present invention, see image 3 . In this embodiment, the inner ring injector assembly is coaxially sleeved in the outer ring injector assembly.

[0057] The inner ring injector assembly is coaxially provided with a central secondary fluid inlet sleeve 100 and an inner tube 200 along the central axis. The inlet C10 caliber of the central secondary fluid inlet sleeve 100 is larger than the outlet caliber. The front end of the inner tube 200 is provided with a cup-shaped flared wall 201, and the inner wall of the cup-shaped flared wall 201 is in sealing connection with the outer wall of the central secondary fluid inlet sleeve 100. The sealed connection can be as follows: image 3 Threaded or flanged connections shown. An annular flat cavity 101 is formed between the concave middle end surface of the cup-shaped flared wall 201 at the front end of the inner tube 200 and the concave bottom groove of the central s...

Embodiment 3

[0066] The third embodiment of the double ring injector of the present invention, see Figure 7 , In this embodiment, the inner ring injector assembly is coaxially sleeved in the outer ring injector assembly. The outer ring injector assembly sets the total mixing output pipe rearwardly along the central axis.

[0067] The inner ring injector assembly is coaxially provided with a central secondary fluid inlet sleeve 100' and an inner tube 200' along the central axis. The diameter of the inlet C10' of the central secondary fluid inlet sleeve 100' is greater than the diameter of the outlet. The bottom surface of the circular platform at the rear end of the central secondary fluid inlet sleeve 100' is provided with a plurality of inclined grooves 102' evenly distributed on the outer wall 101' of the tapered ring sleeve protruding rearward (also can be straight grooves or dense patterns), see Figure 8 . These chutes 102' do not intersect the centerline of the central secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com