Multiplex compound ejector

A technology of ejector and mixing tube, which is applied in the field of multi-channel compound ejector, can solve the problem of low efficiency of a single ejector, and achieve the effects of wide working range, compact overall structure, and short length of mixing tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

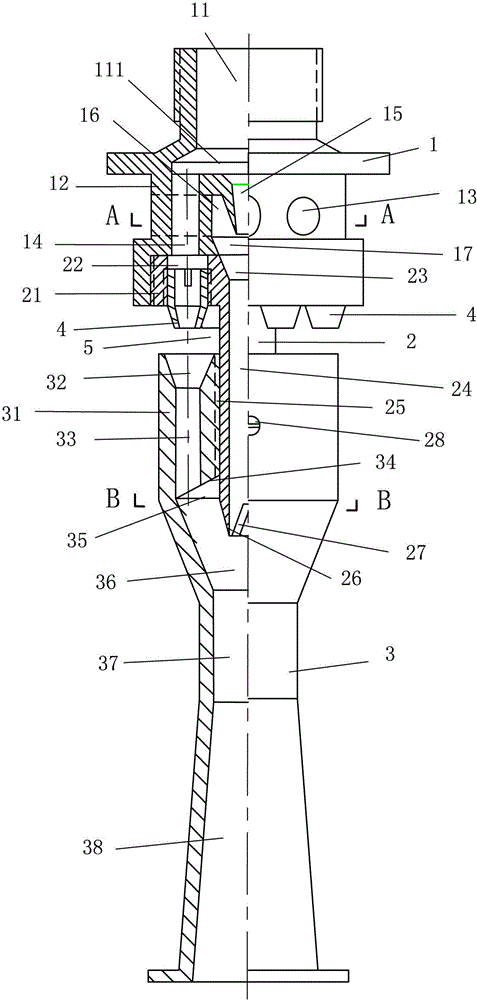

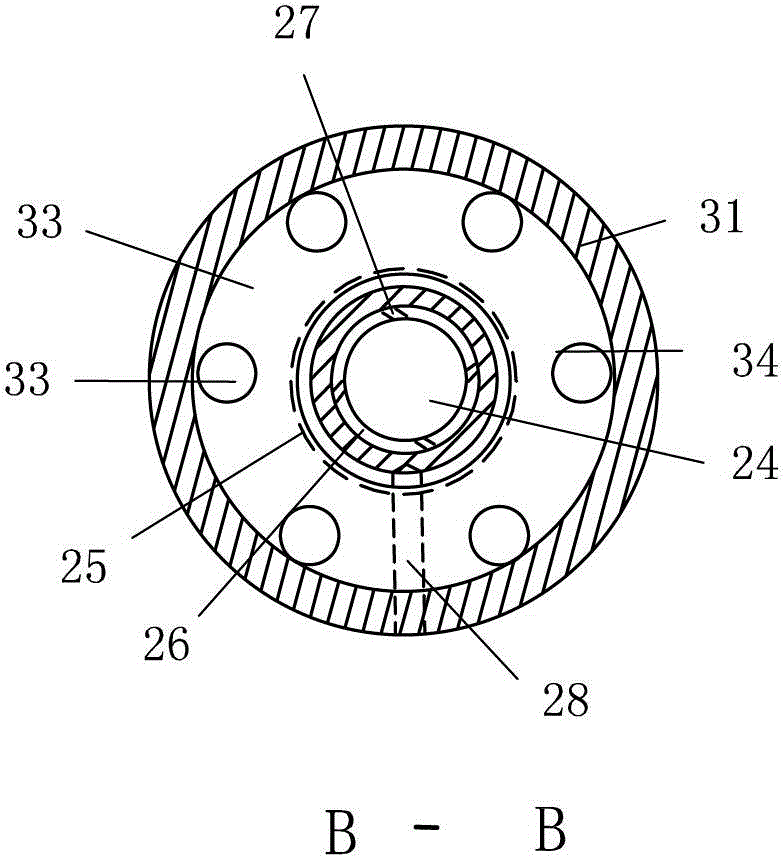

[0036] One embodiment of the multi-channel composite injector of the present invention adopts a high-pressure primary fluid input from the front end, a low-pressure or no-pressure secondary fluid input from the side, and a pressurized mixed flow output from the tail. Its structure, such as figure 1 As shown, it includes a main fluid assembly 1 , an inner pipe assembly 2 , an outer pipe collar 3 and six peripheral nozzles 4 .

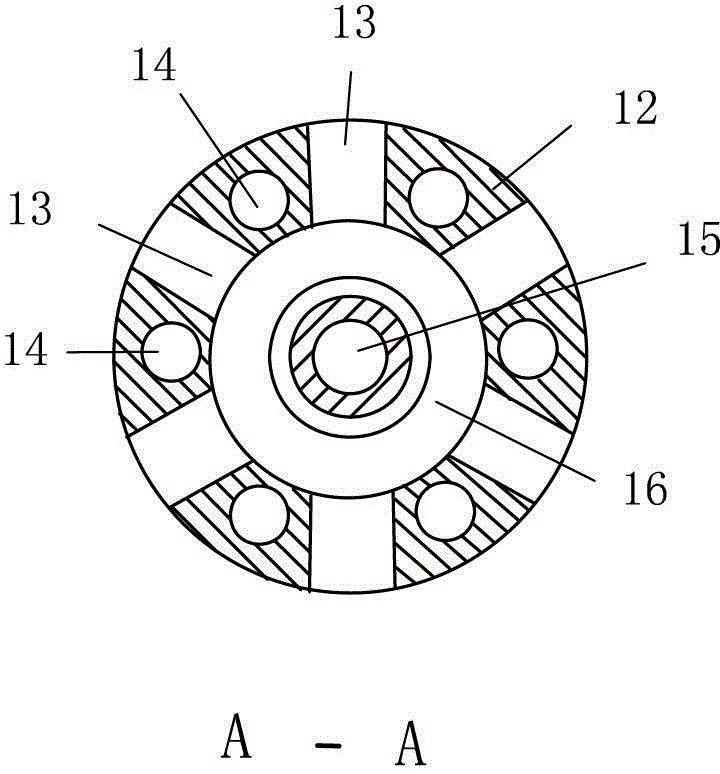

[0037] The center of the top (front end) of the main fluid assembly 1 is provided with a main fluid inlet pipe 11 upwards and a central nozzle 15 downwards. The lower part of the main fluid assembly 1 is provided with an annular distribution sleeve 12, see figure 2 A plurality of horizontal secondary fluid holes 13 and a plurality of vertical primary fluid holes 14 are provided on the peripheral wall of the annular distribution sleeve 12 , and the secondary fluid holes 13 and the primary fluid holes 14 are cross-isolated. The inner cavity of the annula...

Embodiment 3

[0060] In this embodiment, a high-pressure main fluid is input from the front end, a low-pressure or no-pressure secondary fluid is injected from the side, and a mixed flow is output from the tail. Its structure is as follows Figure 5 As shown, it includes the main fluid assembly 100, the inner pipe assembly 200, an outer pipe collar 300 and its extension extension pipe 300' and a central nozzle assembly 1500.

[0061]The top (front end) of the main fluid assembly 100 is centrally provided with a main fluid inlet pipe 1100, and its lower end is provided with an annular flange; The peripheral flanges provided are sealed butt-connected, and a diameter-expanding cavity 11100 is formed in the flared jacket 21100 at the top of the annular flow distribution sleeve 2100 . Six lateral secondary fluid holes 21300 and six vertical primary fluid holes 21400 are provided on the peripheral wall of the annular distribution sleeve 2100 , and the secondary fluid holes 21300 are cross-is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com