Compound ejector

An ejector and duplex technology, applied in jet pumps, non-displacement pumps, machines/engines, etc., can solve the problem of reducing injection ratio and mixing efficiency, lowering injection coefficient or injection ratio, contact rate and Low entrainment efficiency and other problems, to achieve the effect of reduced axial size and weight, various structural forms, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

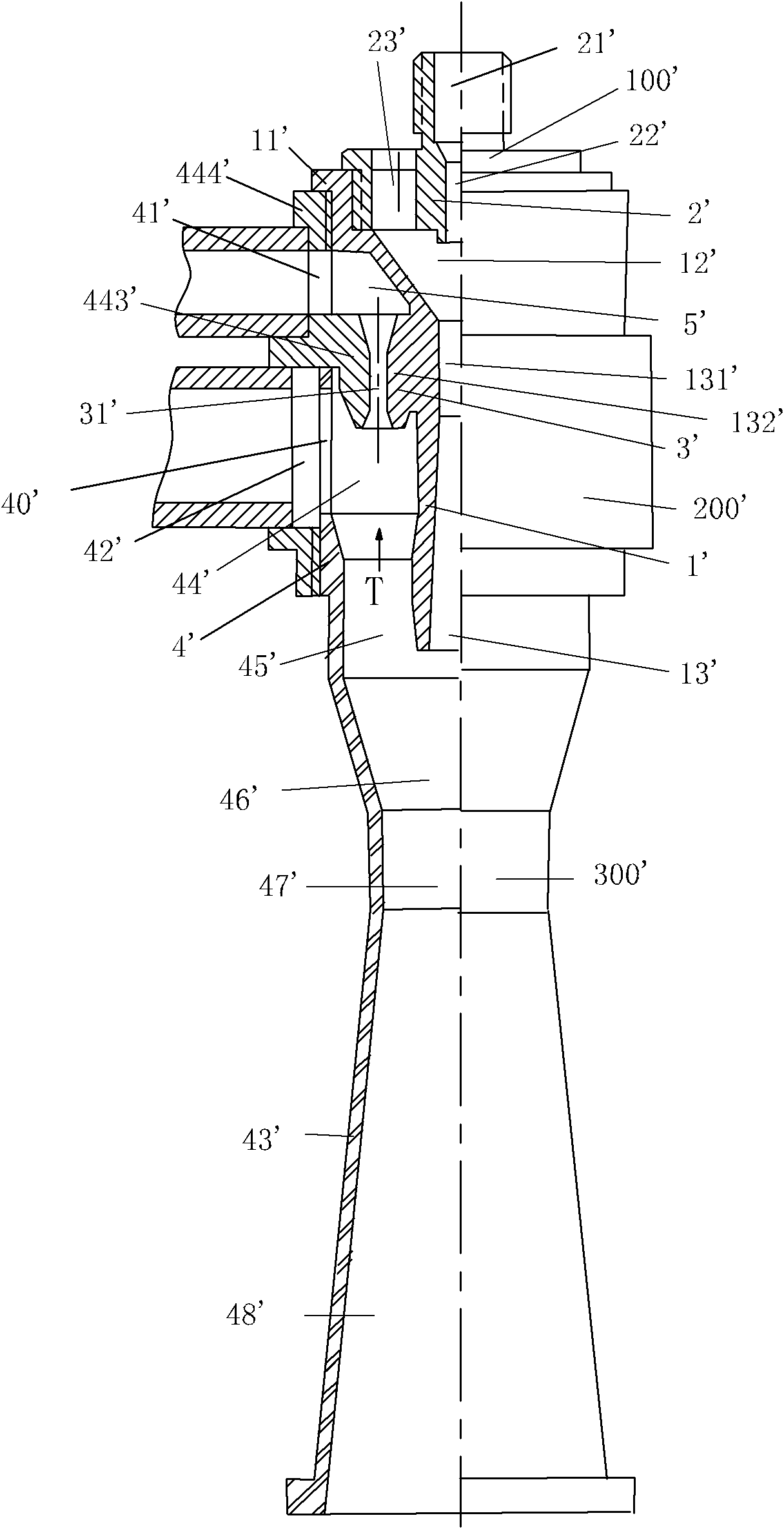

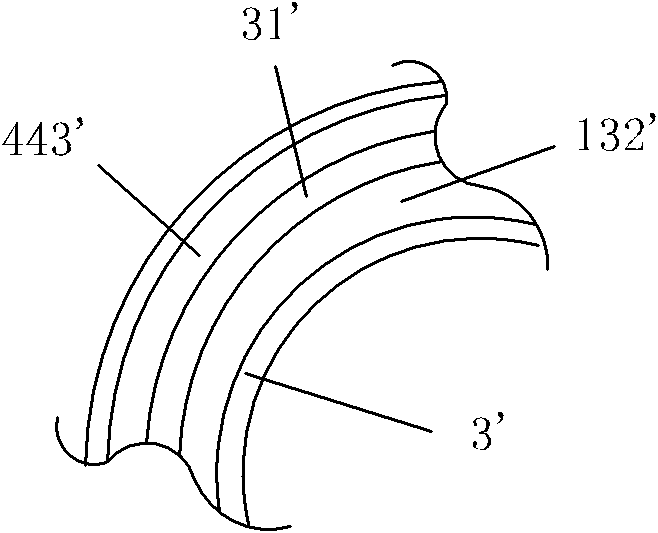

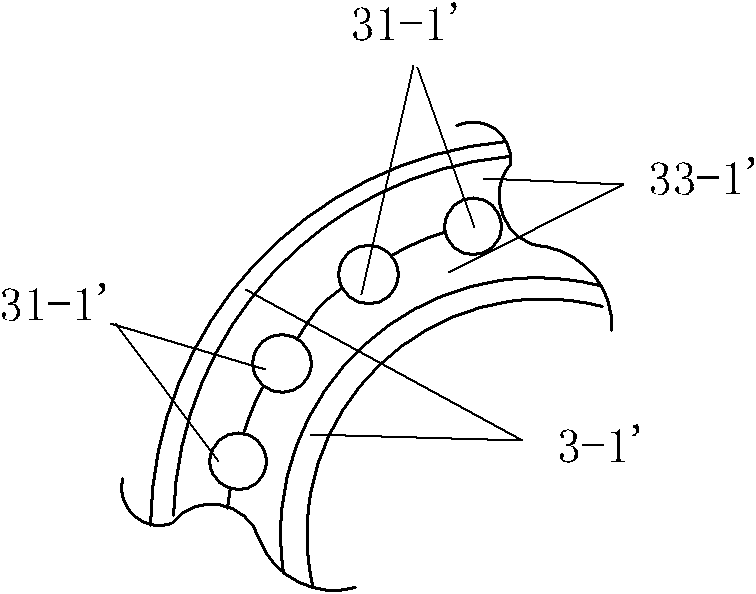

[0048] For the structure of Embodiment 1 of the compound ejector of the present invention, see figure 1 . The compound ejector includes a central ejector 100', an annular ejector 200', and a total ejector 300'. The central nozzle 22' on the inner pipe 1' and the central nozzle seat 2' forms a central ejector 100', and the outer side of the first half of the inner pipe 1' and the inner side of the first half 444' of the outer pipe 4' form an annular nozzle seat 3' and an annular The nozzles 31' and form the annular ejector 200'. The central ejector 100' is coaxially arranged in the annular ejector 200', and the nozzle of the central ejector 100' is connected with the outlet of the surrounding annular ejector 200' and the inner assembly of the rear part 43' in the outer tube 4'. The mixing chamber 46', the overall mixing tube 47' and the overall diffuser tube 48' together constitute the overall ejector 300'.

[0049] Central nozzle seat 2' is provided with central nozzle 22' ...

Embodiment 2

[0059] For the structure of the second embodiment of the compound ejector of the present invention, see Figure 4 . This embodiment includes a central ejector 100 , a circular ejector 200 , a general ejector 300 and a central pre-stage ejector. The middle section of the central ejector 100 is coaxially fixed to the inlet of the diameter-expanding section at the front end of the annular ejector 200, and the rear section of the central ejector 100 is coaxially sleeved in the annular ejector 200 and suspended inside. Around the nozzle of the central mixing tube 13 output end of the central ejector 100, the outlet of the annular mixing tube 45 output end of the annular ejector 200 ejected by it is established, and they are directly connected to the total mixing chamber 46 and the total mixing output pipe 47 to form a total. Ejector 300 .

[0060] The main body of the central ejector 100 is a central nozzle seat 2 arranged in sequence along the central axis front and back and a s...

Embodiment 3

[0069] Such as Figure 8 , Figure 9 , Figure 10 shown. The basic structure and working mechanism of this embodiment are basically the same as those of the first embodiment. The same part will not be described again, the difference is:

[0070] A. Central injector part: the structure of the lower part of the inner tube 10' is basically the same as that of the inner tube 10 in the first embodiment, the difference lies in that the top of the large-diameter flared opening on the upper part of the inner tube 10' shrinks upward and extends out The central short pipe 110' can be or is provided with a first main fluid inlet pipe 210' and directly leads to the central nozzle seat 20' and the central nozzle 220'. The large-diameter trumpet-shaped expansion port on the top of the inner tube 10' shrinks downwards into a small-diameter central mixing tube 130'. The inner cavity of the large-diameter trumpet-shaped expansion port on the top of the inner pipe 10' is the central mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com