A nanofluidic microchannel photovoltaic photothermal integrated evaporator/collector

A nano-fluid and micro-channel technology, applied in photovoltaic power generation, solar collectors, components of solar collectors, etc., can solve the problems affecting the overall performance of the system, large system heat loss, large light loss, etc. High heat and mass transfer rate, good heat transfer effect, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

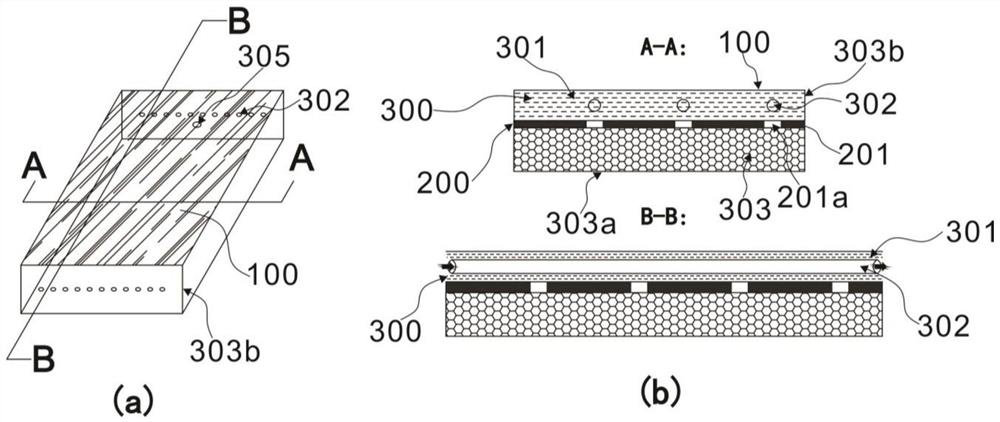

[0038] refer to figure 1 , a schematic diagram of the overall structure of a nanofluidic microchannel photovoltaic photothermal integrated evaporator / heat collector is provided, and its structure is as follows figure 1 As shown in (a) and (b), it includes a cover plate 100, and a photovoltaic cell layer 200; the photovoltaic cell layer 200 is located on the bottom side of the cover plate 100, and a nanofluidic flow channel 300 is formed between the photovoltaic cell layer 200 and the cover plate 100 , the nanofluid channel 300 is filled with nanofluid 301 , and the microchannel 302 arranged in the nanofluid channel 300 .

[0039] Specifically, a plurality of independent photovoltaic cells 201 are arranged in the photovoltaic cell layer 200 , the photovoltaic cells 201 are evenly arranged in the photovoltaic cell layer 200 , a light transmission gap 201 a is formed between two adjacent photovoltaic cells 201 , and the microchannels 302 are arranged In the nanofluid flow channe...

Embodiment 2

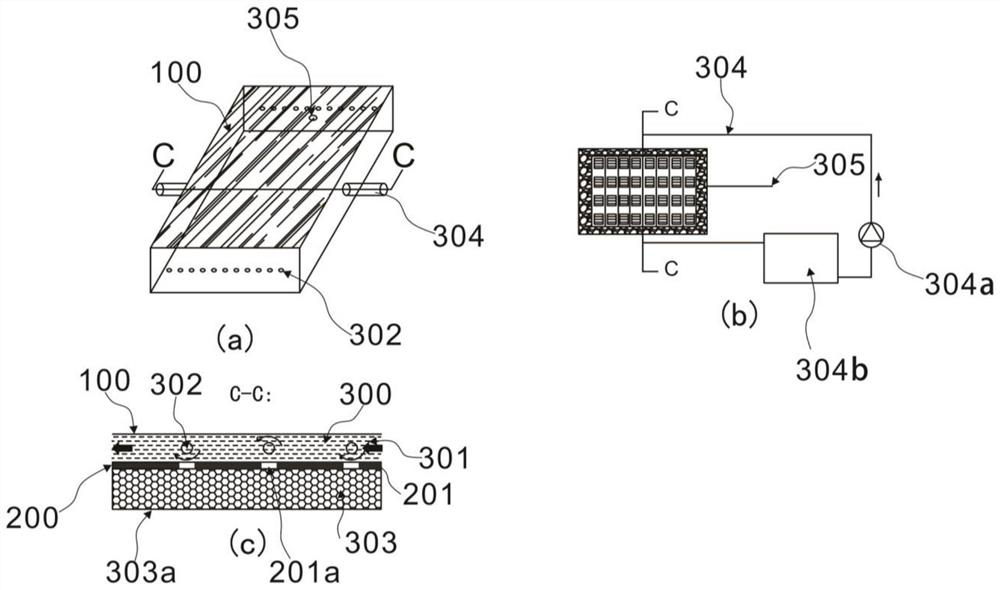

[0043] refer to figure 2 , provides a forced circulation type nanofluidic microchannel photovoltaic photothermal integrated evaporator / heat collector, the system structure of which is as follows figure 2 As shown in (a) and (c), it includes a cover plate 100, and a photovoltaic cell layer 200. The photovoltaic cell layer 200 is located on the bottom side of the cover plate 100, and a nanofluidic flow channel 300 is formed between the photovoltaic cell layer 200 and the cover plate 100. , the nanofluid channel 300 is filled with nanofluid 301 , and the microchannel 302 arranged in the nanofluid channel 300 .

[0044] Specifically, a plurality of independent photovoltaic cells 201 are arranged in the photovoltaic cell layer 200 , the photovoltaic cells 201 are evenly arranged in the photovoltaic cell layer 200 , a light transmission gap 201 a is formed between two adjacent photovoltaic cells 201 , and the microchannels 302 are arranged In the nanofluid flow channel 300, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com