Gas hydrate accelerant based on nanoparticles and Gemini surfactant and application of accelerant

A technology of surfactants and gas hydrates, applied in the direction of gas fuels, other chemical processes, chemical instruments and methods, etc., can solve the problems of deposition, promotion efficiency that cannot meet the requirements of industrial applications, cluster aggregation, etc., and achieve biological safety High, excellent surface activity, the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

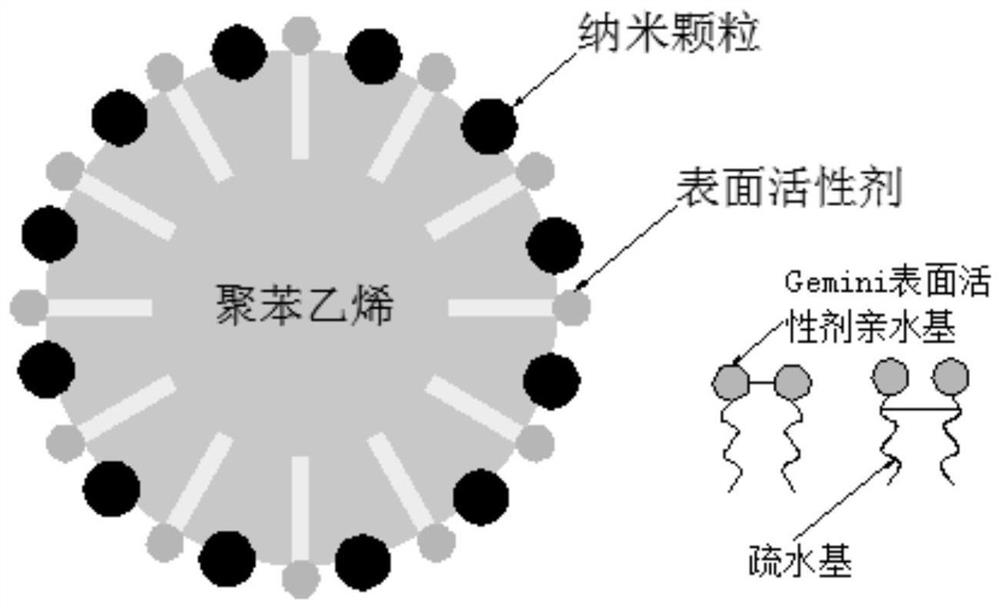

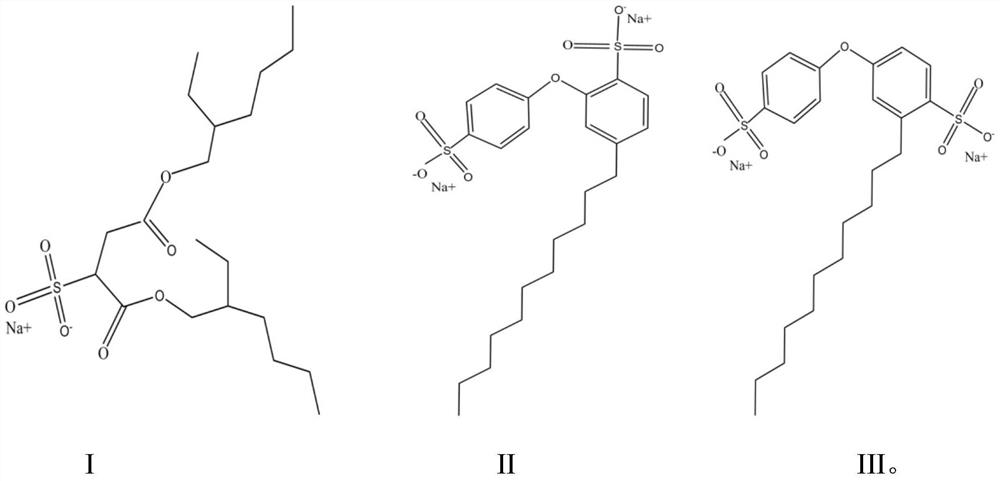

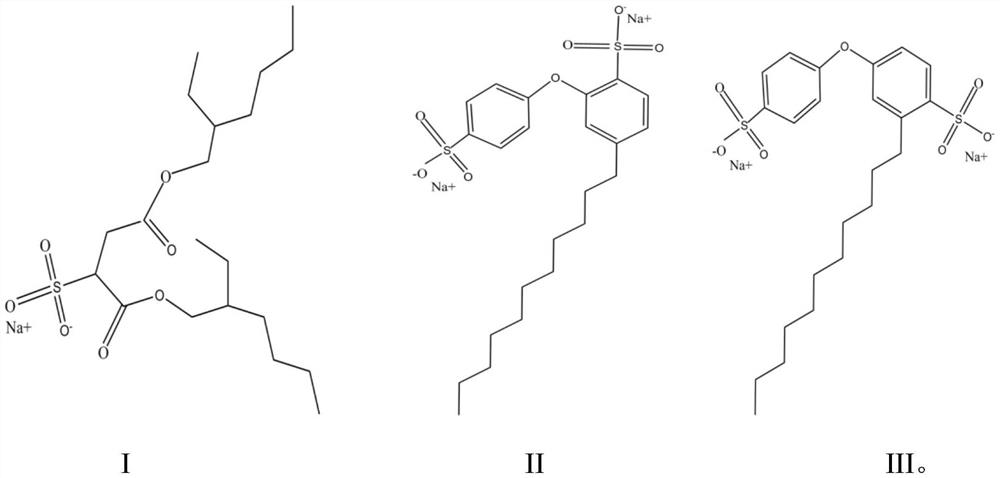

[0035] The preparation method provided by the invention has simple process, mild conditions, low original cost and broad application prospect. Compared with traditional single-chain anionic surfactants (such as sodium lauryl sulfate SDS), the Gemini surfactant used in the present invention has double hydrophilic and hydrophobic groups, has lower critical micelle concentration and stronger surface reduction Tension ability, showing more excellent surface activity; and has a very low Kraff point, strong temperature stability, and high biological safety.

[0036] The experimental methods described in the following examples can be carried out with reference to conventional techniques for the process parameters not specifically noted; the reagents and materials can be obtained from commercial sources unless otherwise specified.

[0037] The method for detecting and measuring this method to prepare product promoting effect is as follows:

[0038] The detection equipment is a visual...

Embodiment 1

[0043] Firstly, styrene was rinsed three times with 10% sodium hydroxide solution to remove hydroquinone as a polymerization inhibitor, then washed three times with deionized water, and stored in a freezer at -20°C. Add 95g of deionized water, 0.1g of nano Fe 3 o 4 and 1.0g emulsifier AOT, turn on the magnetic stirring at 300rpm and stir for 30min, and then use ultrasonic waves to disperse the liquid. Vacuum the nitrogen to remove the air in the pipeline. Add 5.0g styrene and 0.1g ammonium persulfate, raise the temperature to 70°C, under the protection of nitrogen, carry out emulsion polymerization reaction, keep stirring for 5h, and naturally cool down to room temperature to obtain the product 10% Fe 3 o 4 &AOT@PSN-1.

[0044] Detection and determination:

[0045] The above-mentioned accelerator is configured as 1.0mol surfactant AOT / L aqueous solution, and under the conditions of initial temperature 6°C and initial pressure 8.0MPa, the natural gas hydrate promotion perf...

Embodiment 2

[0047] The same operating steps as in Example 1, quantitatively weigh 90g deionized water, 0.1g nanometer Fe 3 o 4 , 1.0g emulsifier AOT, 10.0g styrene and 0.1g ammonium persulfate, emulsion polymerization for 5h, after the reaction, the product 10% Fe 3 o 4 &AOT@PSN-2.

[0048] Detection and determination:

[0049] The above-mentioned promoters are configured as 0.5mol, 1.0mol, 2.0mol surfactant AOT / L aqueous solution, and under the conditions of initial temperature 6°C and initial pressure 8.0MPa, test and determine The accelerator accelerates the induction time of hydrate formation, and the experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com