A 3D printing integrated heat sink and its application in phased array antenna

A technology for radiators and heat exchange containers, applied to antennas, antenna arrays, antenna components, etc., can solve the problem of large heat exchange dead volume of heat exchange containers, uneven heat exchange of heat exchange devices, and no consideration of heat exchange uniform temperature performance and other problems, to achieve the effect of large number of partitions, small spacing, and pressure pulsation suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

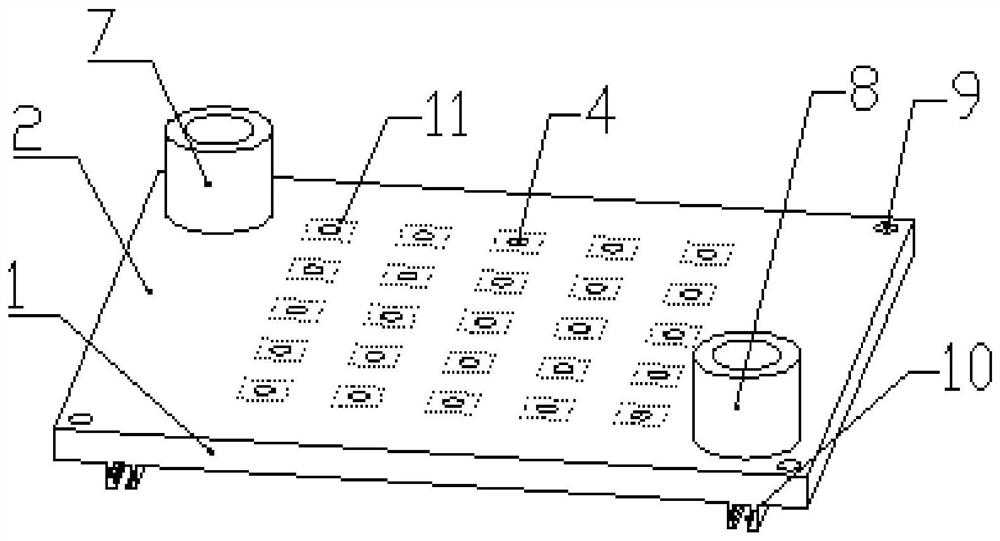

[0042] A radiator, including a heat exchange container for heat exchange and conduction with a heat source, and a liquid injection port 7 and a liquid outlet 8 for heat exchange liquid to flow into and out of the heat exchange container. The flow channel for reducing fluid pressure drop and performing heat exchange, the liquid injection port 7 is located at the largest end of the flow channel in the heat exchange container, and the liquid outlet 8 is located at the smallest end of the flow channel in the heat exchange container.

[0043] Description of the heat exchange container: The heat exchange container is the same as the existing technology, and it only needs to ensure that the heat exchange container is isolated from the heat source and the heat exchange body. It can be in the shape of a plate, a column, a cube, or a "back" As the heat exchange tube used in the shell-and-tube heat exchanger and the tube-sheet heat exchanger in the prior art, it is only necessary to gradu...

Embodiment 2

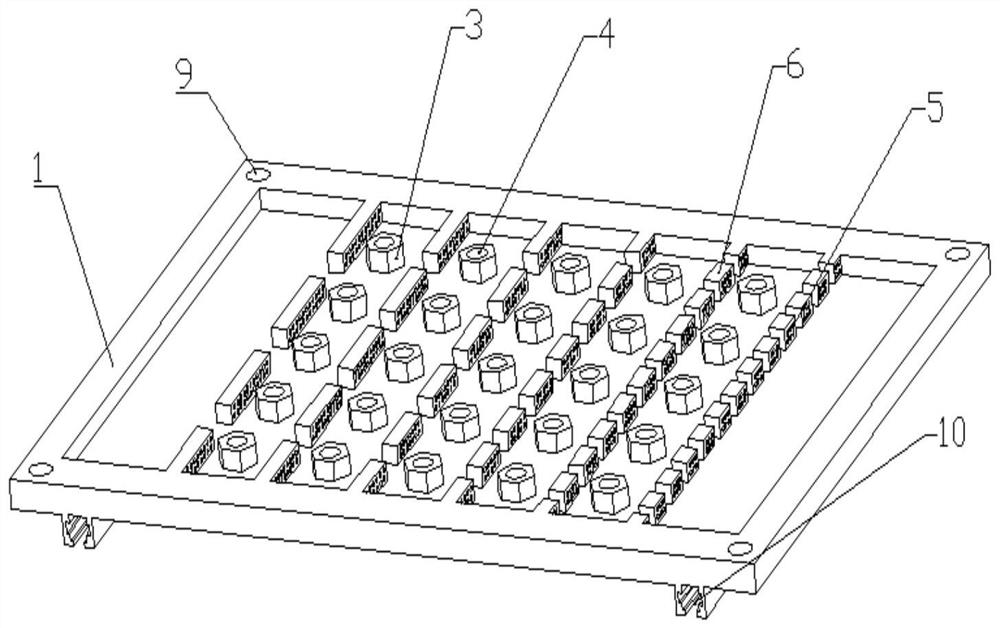

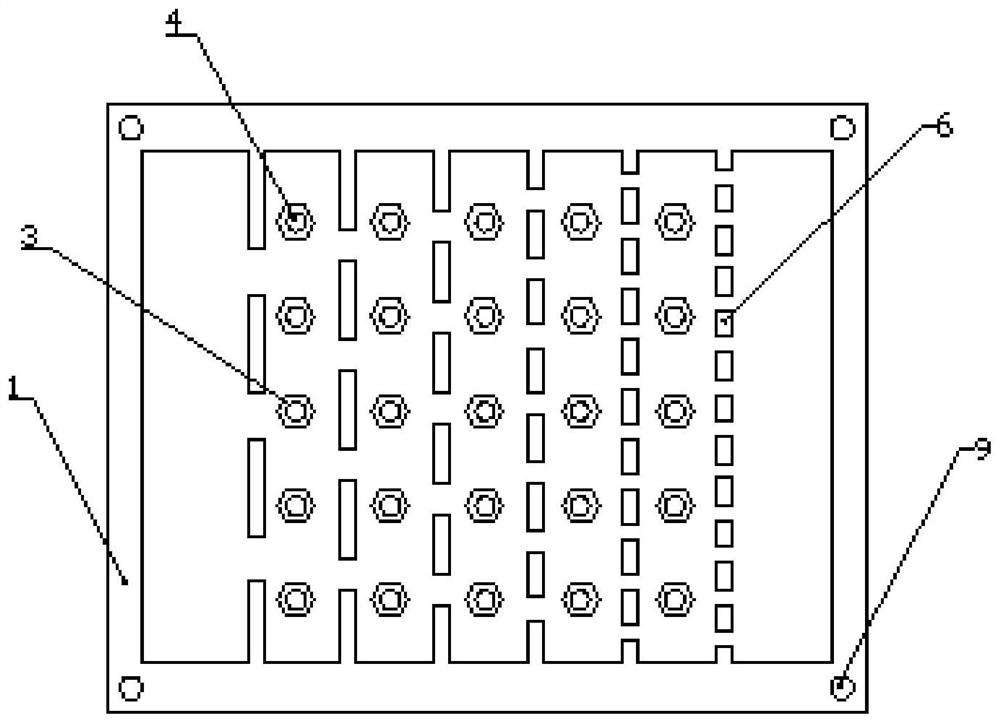

[0046] The difference between this embodiment and Embodiment 1 is: 1) Provide a structural form of the heat exchange container; 2) Provide a specific structure in which the circulation channel in the heat exchange container gradually increases; 3) For the control array antenna micro Optimize the design of the heat dissipation structure for the specific heat dissipation scenario of the channel; 4) Optimize the design of the position of the liquid injection port 7 and the liquid outlet 8 so that the heat exchange liquid can fully flow through the heat exchange container.

[0047] The repeated parts of this embodiment and embodiment 1 will not be repeated, and only point out the difference here:

[0048] 1) In order to specifically provide a structural form of a heat exchange container, see figure 1 and figure 2 In this embodiment, the heat exchange container is plate-shaped, and is composed of a cold plate 1 and a cover plate 2 that are combined with each other to form a close...

Embodiment 3

[0055] The difference between this embodiment and Embodiment 2 is that Embodiment 2 is for dissipating heat for a 5×5 phased array antenna, while this embodiment is for dissipating heat for an 8×8 phased array antenna, see Figure 5 The only difference between this embodiment and embodiment 2 is that the number of partitions 6 and the number of heat exchange units are adjusted accordingly.

[0056] By analogy, the present invention can be used not only for 5×5 phased array antennas or 8×8 phased array antennas for heat dissipation, but also for more types of phased array antennas for heat dissipation. Since there are many models that can be used, No need to go into details this time, as long as the radiator structure of the present invention is used to dissipate heat for the phased array antenna, it should be included in the scope of protection of this application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com