Nafion/sulfonated SiO2 molecular sieve composite proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and molecular sieve, applied in the field of proton exchange membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

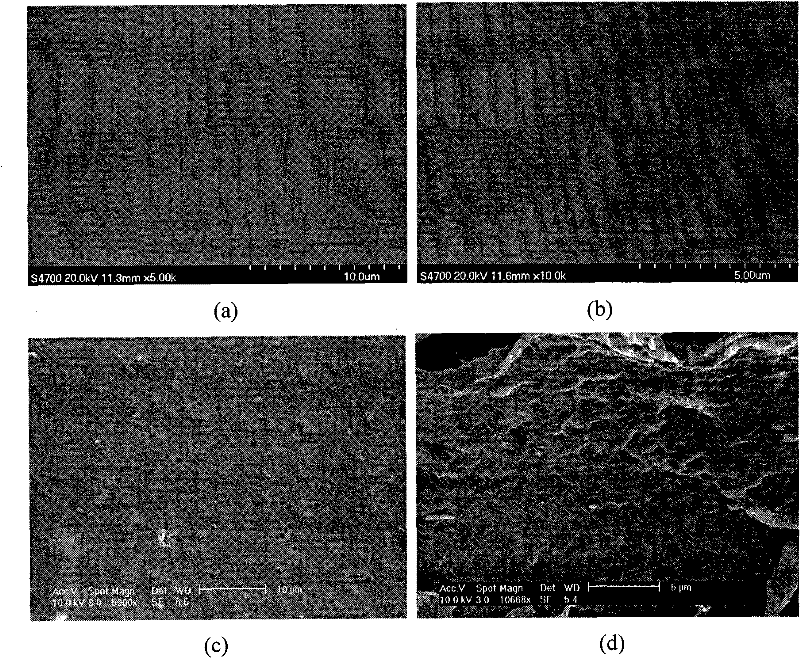

[0028] Take by weighing 50g 5wt% Nafion alcohol solution and 47.5g DMF and mix and carry out vacuum distillation, remove the alcohols of low boiling point, obtain Nafion-DMF mixed solution; 2 Molecular sieves were added to 15ml of 0.5M sulfuric acid solution, stirred for 30min, and then the whole solution was dried in an oven at 100°C for 24h to obtain sulfonated SiO 2 Molecular sieve powder;

[0029] According to sulfonated SiO 2 The content of molecular sieve is 1%, weigh 0.0063g sulfonated SiO 2 Pour the molecular sieve into the Erlenmeyer flask, then pour 6g DMF, ultrasonically disperse for 30 minutes, then add 15g of the above-mentioned Nafion-DMF mixed solution into the Erlenmeyer flask, continue ultrasonically dispersing for 30 minutes, and obtain a milky white cast film after standing for defoaming liquid; the casting solution is cast into a clean and flat glass petri dish, heat-treated in an oven at 60°C for 2 hours, at 80°C for 2 hours, and at 100°C for 12 hours to...

Embodiment 2

[0031] Take by weighing 50g 5wt% Nafion alcohol solution and 47.5g DMF and mix and carry out vacuum distillation, remove the alcohols of low boiling point, obtain Nafion-DMF mixed solution; 2 Molecular sieves were added to 10ml of 0.5M sulfuric acid solution, stirred for 45min, and then the whole solution was dried in an oven at 100°C for 24h to obtain sulfonated SiO 2 Molecular sieve powder;

[0032] According to sulfonated SiO 2 The content of molecular sieve is 3%, weigh 0.0189g sulfonated SiO 2 Pour the molecular sieve into the Erlenmeyer flask, then pour 6g of DMF, ultrasonically disperse for 45 minutes, then add 15g of the above-mentioned Nafion-DMF mixed solution into the Erlenmeyer flask, continue ultrasonically dispersing for 30 minutes, and obtain a milky white cast film after standing for defoaming liquid; the casting solution is cast into a clean and flat glass petri dish, heat-treated in an oven at 60°C for 2 hours, at 80°C for 2 hours, and at 100°C for 12 hours...

Embodiment 3

[0034] Take by weighing 50g 5wt% Nafon alcohol solution and 45g DMF and mix and carry out vacuum distillation, remove the alcohols of low boiling point, obtain Nafion-DMF mixed solution; 2 Molecular sieves were added to 15ml of 0.5M sulfuric acid solution, stirred for 60min, and then the whole solution was dried in an oven at 100°C for 24h to obtain sulfonated SiO 2 Molecular sieve powder;

[0035] According to sulfonated SiO 2 The content of molecular sieve is 5%, weigh 0.0316g sulfonated SiO 2 Pour the molecular sieve into the Erlenmeyer flask, then pour 4g DMF, ultrasonically disperse for 30 minutes, then add 12g of the above-mentioned Nafion-DMF mixed solution into the Erlenmeyer flask, continue ultrasonically dispersing for 45 minutes, and obtain a milky white cast film after standing for defoaming liquid; the casting solution is cast into a clean and flat glass petri dish, heat-treated in an oven at 60°C for 2 hours, at 80°C for 2 hours, and at 100°C for 12 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com