Reinforced heat and mass transfer pipe insert and heat and mass transfer pipe

A technology for enhancing heat and mass transfer, applied in the field of heat and mass transfer, can solve the problems of difficult disassembly, reduced strength of the circular tube, and narrow application range, and achieves improved heat and mass transfer coefficient, simple structure, and easy manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

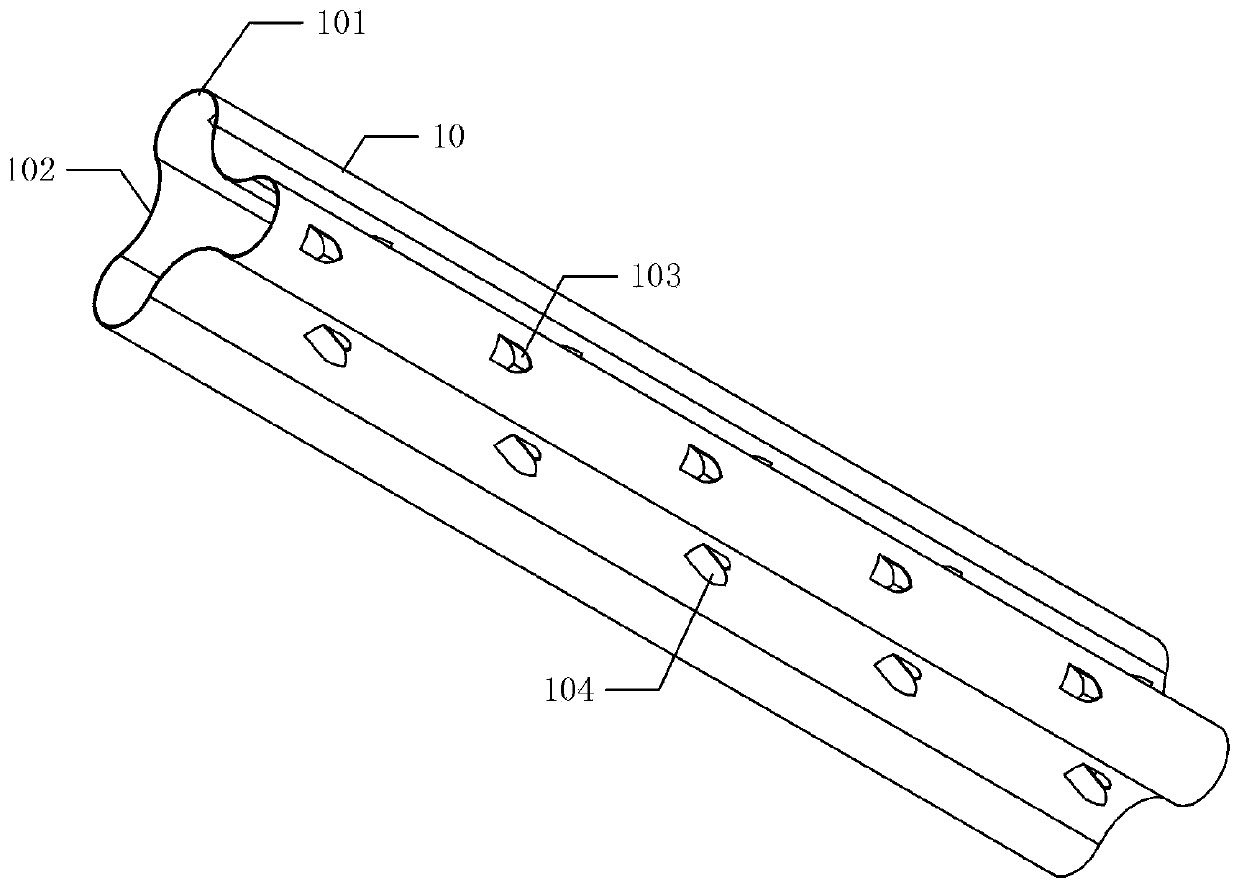

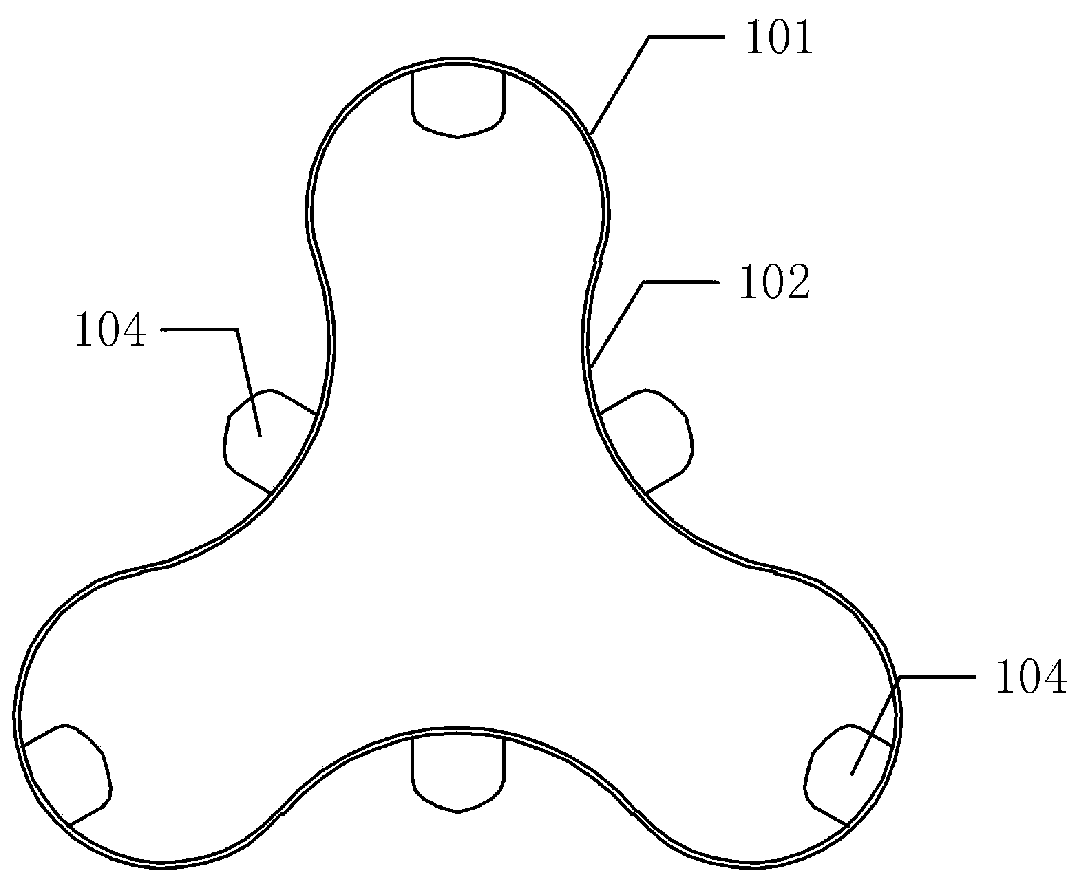

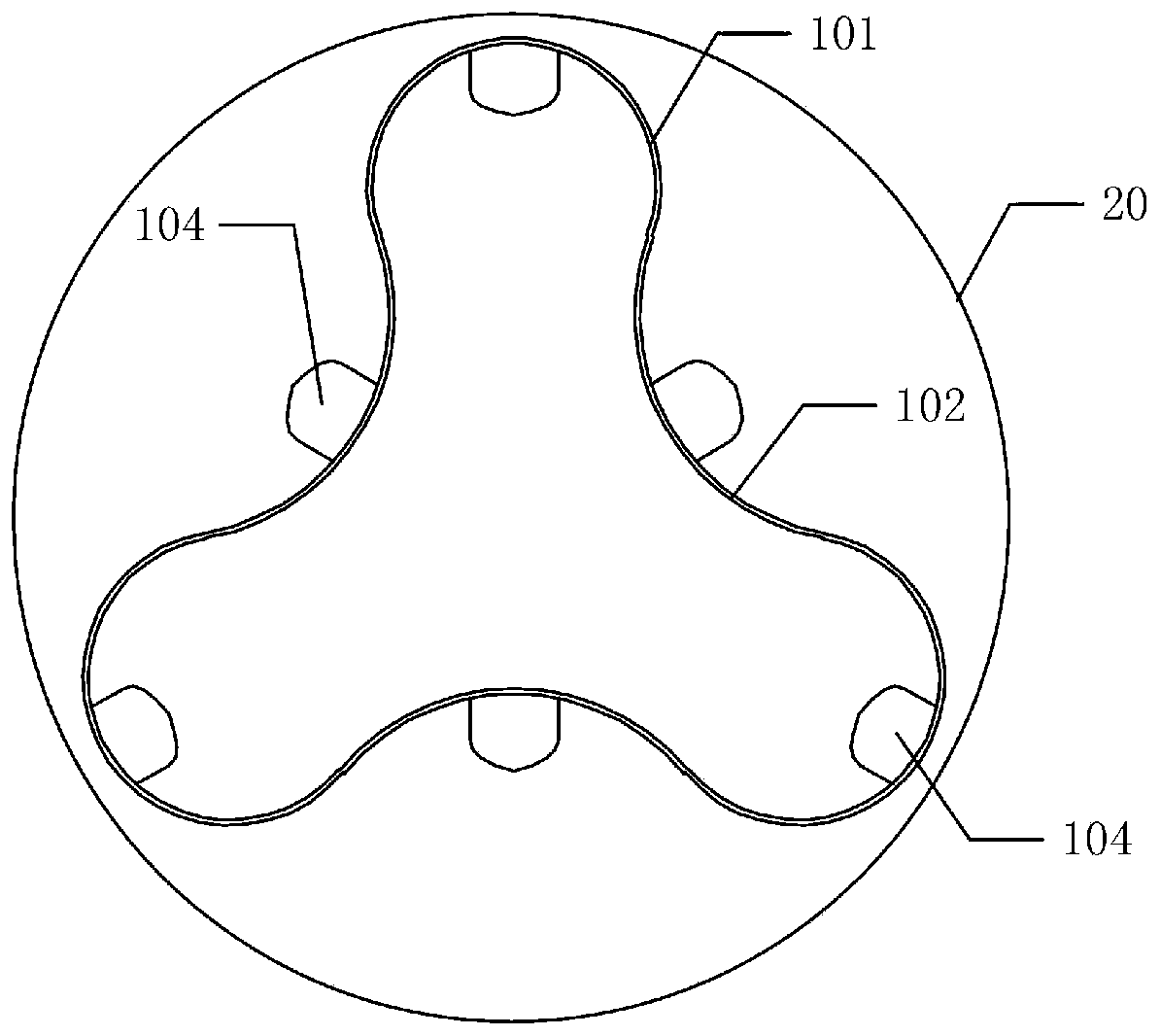

[0028] like Figure 1 to Figure 3 As shown, the present invention provides a tube insert for enhanced heat and mass transfer, the insert is a tubular body 10, the tube wall of the tubular body 10 is composed of a plurality of alternately arranged near-wall guides 101 and central guides 102, the near-wall guide part 101 is a convex structure arranged axially along the tubular body 10, and the central guide part 102 is a concave structure arranged axially along the tubular body 10; Spoiler holes 103 are uniformly arranged on the near-wall guide part 101 and the center guide part 102 , and a spoiler 104 is provided at one end of the spoiler hole 103 .

[0029] When the fluid flows at a low speed in the heat and mass transfer tube 20, it presents a laminar flow, and its particle moves smoothly and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com