Radiator

A radiator and heat source technology, applied in the direction of heat sinks, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of insufficient heat exchange, low air velocity, and reliability of components, so as to enhance the heat dissipation efficiency, change the Air flow state, the effect of improving the air flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

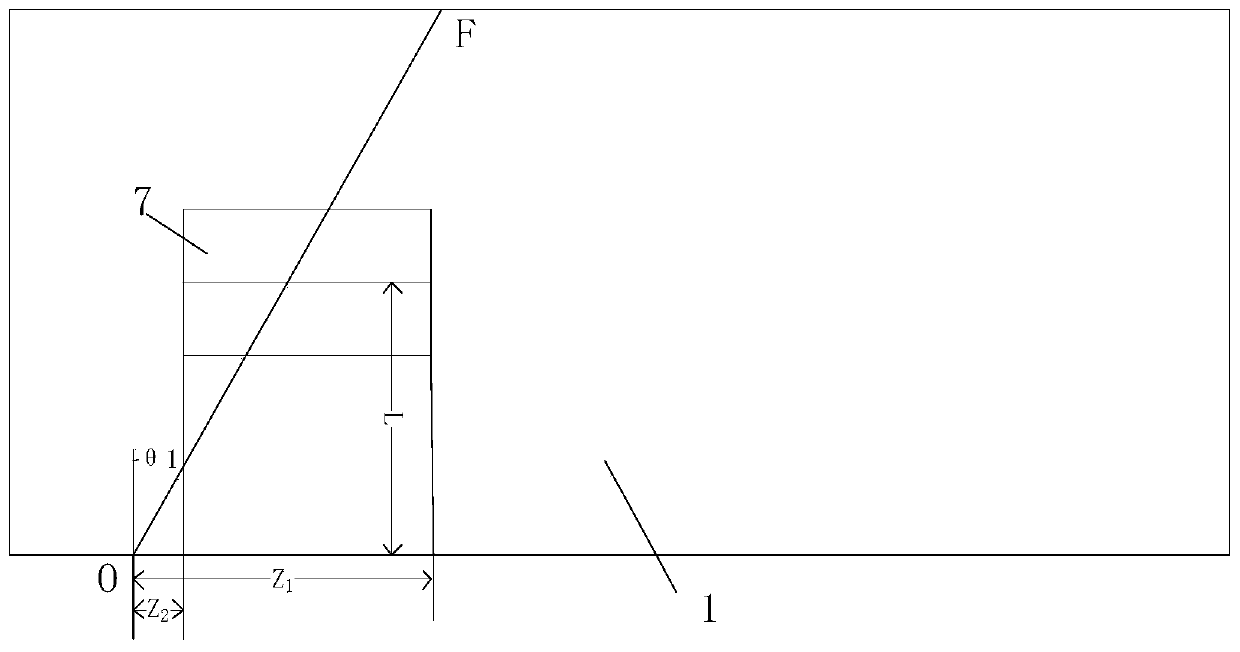

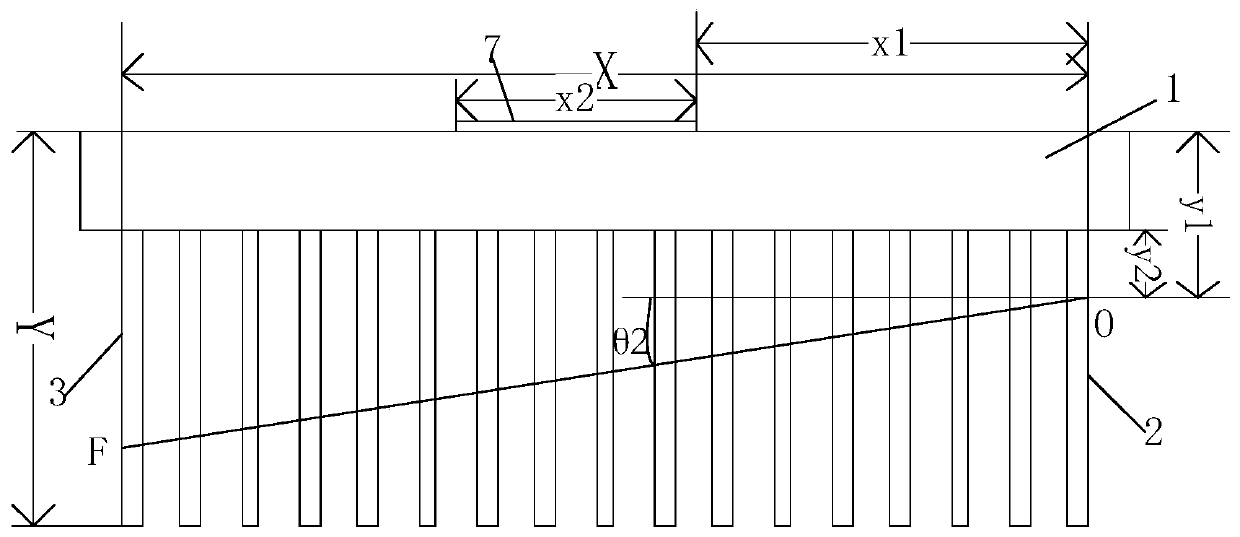

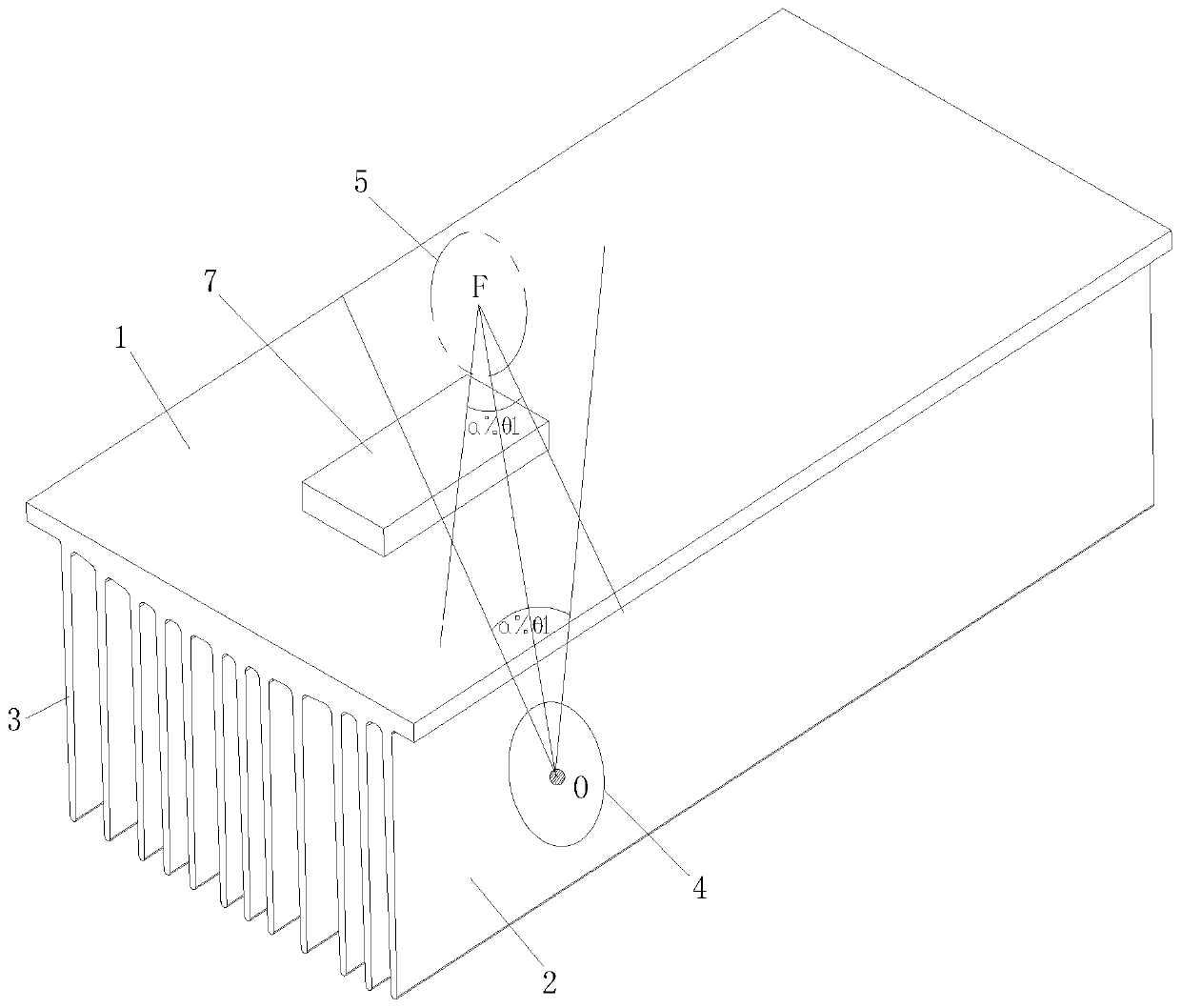

[0027] see in conjunction Figure 1 to Figure 4 As shown, according to the embodiment of the present application, the heat sink includes a substrate 1 and fins, a plurality of fins are arranged at intervals on the substrate 1, each of the fins is respectively provided with flow holes, and the fins It forms a preset angle with the direction of the airflow. Along the direction of the airflow, the fins include the first end fin 2 that first contacts the airflow and the end fin 3 that finally contacts the airflow. The flow hole on the fin 2 is the head flow hole 4, the flow hole located on the end fin 3 is the end flow hole 5, and the head flow hole 4 and the end flow hole The flow holes between 5 are the middle flow holes 6, and the middle flow holes 6 are all located on the central line OF connecting the head flow holes 4 and the end flow holes 5.

[0028] This application changes the air flow mode of the radiator, so that the direction of the air flow is not along the extensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com