A microchannel heat exchange device that enhances the mixing of two microfluids

A technology of mixing channels and fluid channels, which is applied in the field of heat exchangers, can solve problems such as difficult operation and complex structure, and achieve the effects of promoting uniform heat transfer, optimizing wedge-shaped structure, and saving materials and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

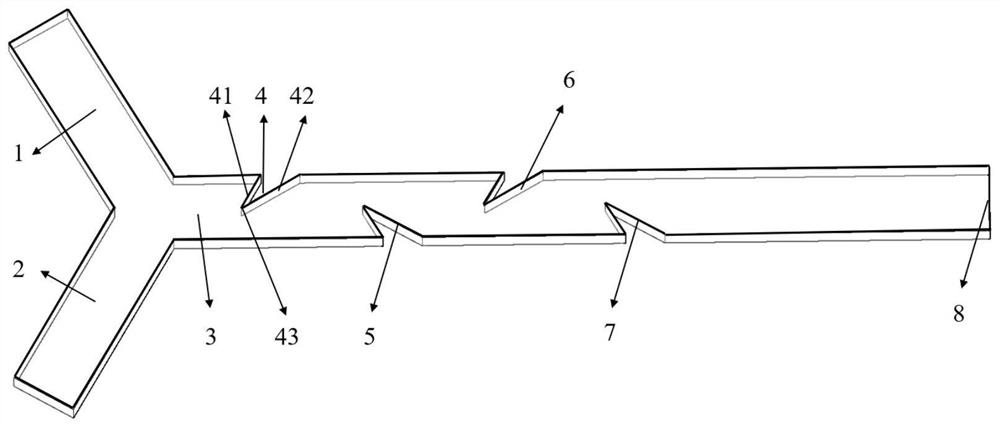

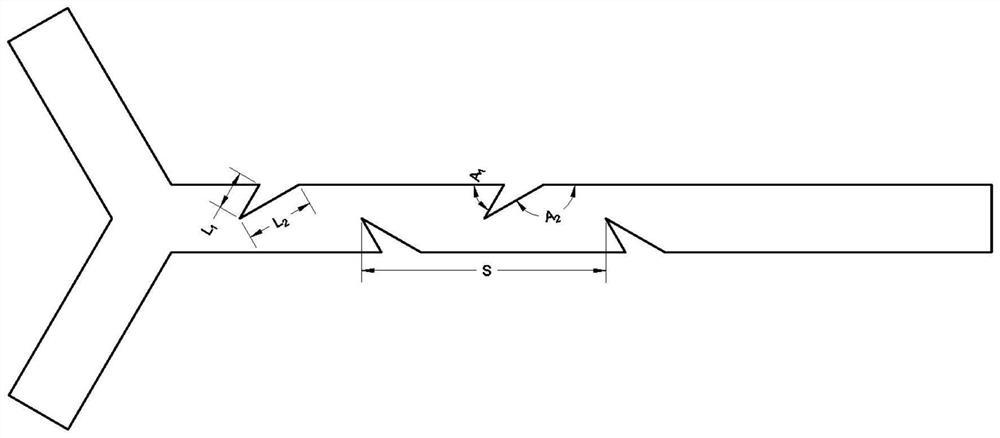

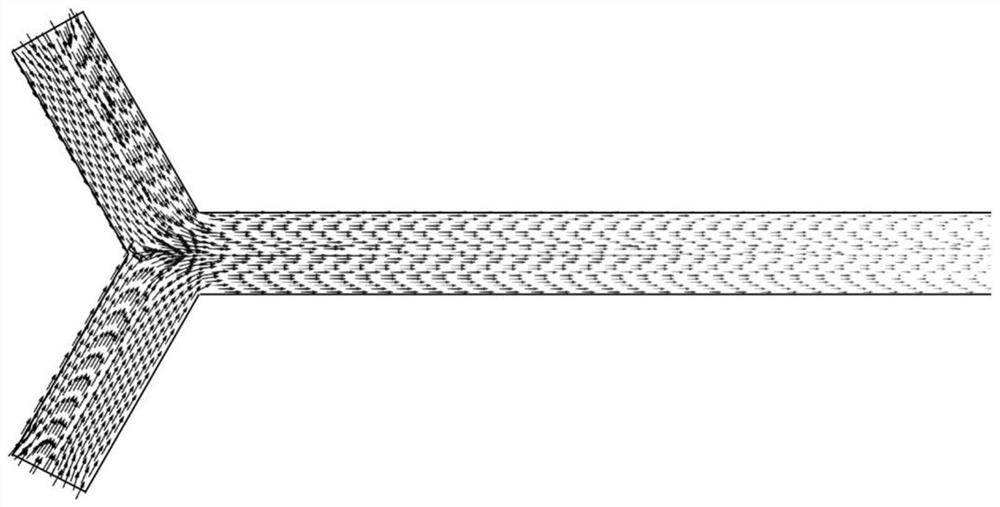

[0029] figure 1 Disclosed is a microchannel heat exchange device for enhancing the mixing of two microfluids. like figure 1 As shown, the device includes a first fluid channel 1, a second fluid channel 2 and a mixing channel 3; the outlets of the first fluid channel 1 and the second fluid channel 2 are connected to the inlet of the mixing channel 3, and the first fluid channel 1. The second fluid channel 2 is arranged obliquely to the mixing channel 3, and a plurality of wedge-shaped structures 4-7 are arranged on the inner wall of the mixing channel 3, and the extending direction of the wedge-shaped structures is opposite to the fluid flow direction. certainly, figure 1 The four wedge-shaped structures are only schematically shown in the figure, and are not limited to figure 1 in the quantity.

[0030] Because the micro-mixer channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com