Double-speed internal jetting flashy flow efficient washing roller

A high-efficiency, water-washing technology, applied in the processing of textile material drums, textiles and papermaking, liquid/gas/vapor processing of variable-length textile materials, etc. Contamination, improved washing efficiency, and the effect of shortening length

Inactive Publication Date: 2013-05-08

荆旭东

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] As far as the development process of the washing machine is concerned, it is to improve its washing efficiency from the mechanical and physical effects. The earlier horizontal guide rollers have a significant washing efficiency for chemicals, which are suitable for washing after bleaching and dyeing, but for those with adhesive Due to the less water exchange and short puffing time of the horizontal guide roller washing machine, the washing effect is poor

In order to overcome the above shortcomings, the direct guide roller back-shaped cloth-wearing flat washing machine came into being. It uses high-pressure powerful spraying and large-flow circulating spraying to achieve better washing effect, but it can reduce the consumption of water, steam and electricity and reduce pollution. , There are defects in shortening the length of the production line, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

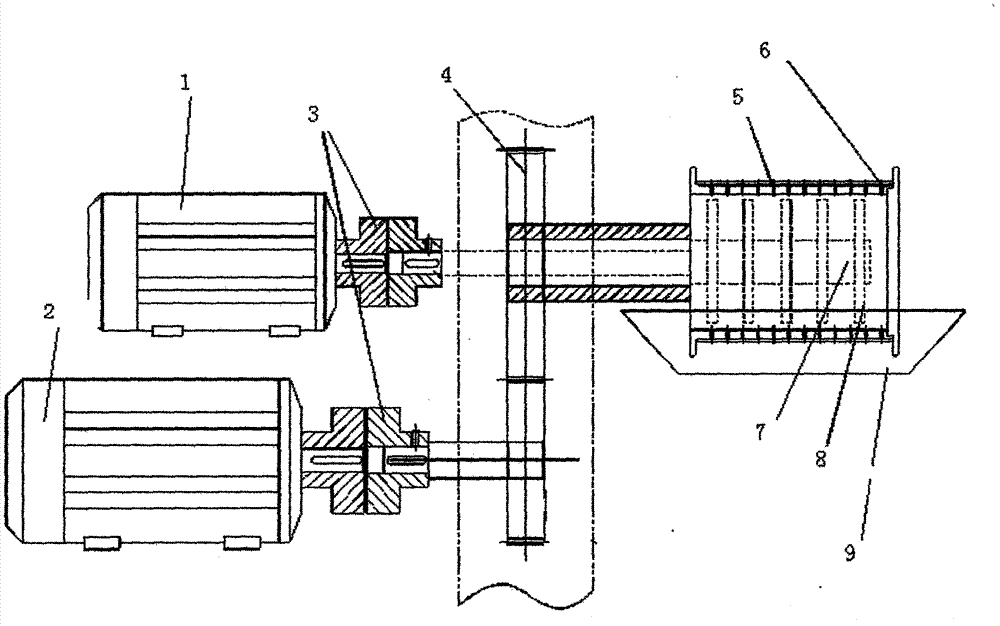

Login to View More Abstract

The invention relates to a washing machine steeping roller which is composed of parts such as a steeping roller, an inner shaft, a gear, a coupler and a motor. A steeping roller transmission motor is meshed with a gear installed on a steeping roller cylindrical shaft through the gear, an inner shaft transmission motor is directly connected with the inner shaft through the coupler, rotation speed of the steeping roller is same with the fiber speed, rotation speed of inner shaft transmission is larger than steeping roller transmission speed, and directions of the steeping roller transmission and the inner shaft transmission are opposite. When the inner shaft rotates, water washing liquor is stirred by a fin to jet a part of the liquor on the inside of fibers on the steeping roller and a part of the liquor on water washing liquor in a water washing groove through a liquid throwing hole, washing effects are improved, consumption of water, gas and electricity is reduced, pollution is reduced and length of a production line is shortened.

Description

technical field [0001] The invention belongs to the technical field of textile equipment, and in particular relates to a component of a wet spinning and printing and dyeing device, in particular to a high-efficiency water washing roller for a washing machine with a dual-speed internal jet gushing flow. Background technique [0002] The washing machine is a general-purpose unit machine widely used in wet spinning and dyeing and finishing equipment. Improving its washing efficiency has a great effect on ensuring product quality, reducing water, steam, and electricity consumption, reducing pollution, and shortening the length of the production line. Especially for energy conservation, it has more practical significance. [0003] As far as the development process of the washing machine is concerned, it is to improve its washing efficiency from the mechanical and physical effects. The earlier horizontal guide rollers have a significant washing efficiency for chemicals, which are...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06B3/02D06B23/02

CPCD06B23/025D06B3/201D06B5/08D06B3/34

Inventor 荆旭东

Owner 荆旭东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com