Solar Automatic soaking and gathering-heat pipe, slot-typed assembly, thermal power generating system and craft

一种太阳能、聚热管的技术,应用在太阳能光热发电领域,能够解决真空集热管上下温差大、毁坏真空集热管爆管事故、导热性导热性差别很大等问题,达到避免爆管事故的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and the best mode of implementation.

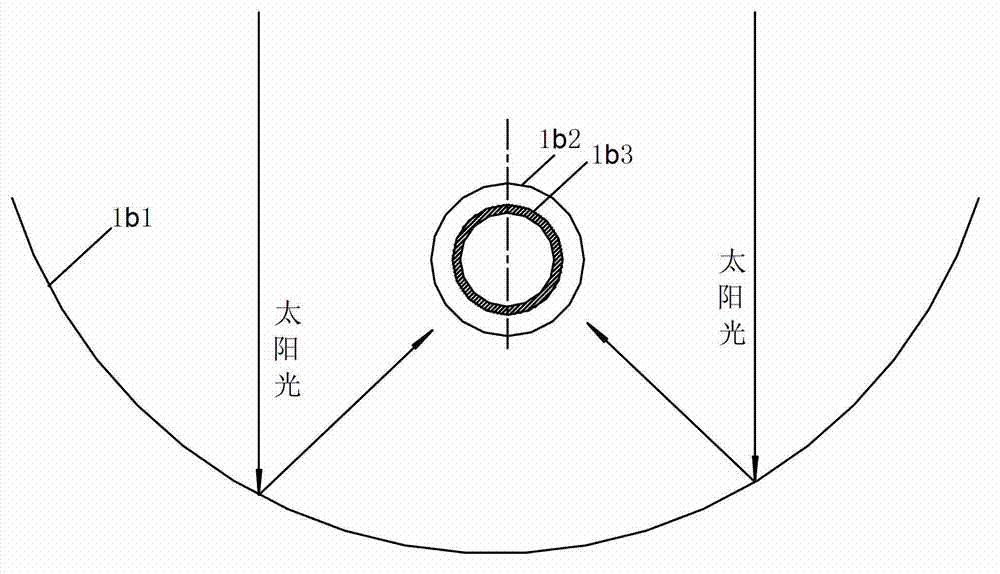

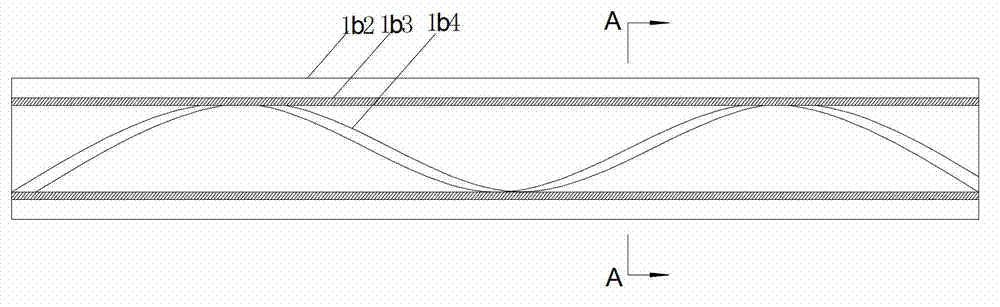

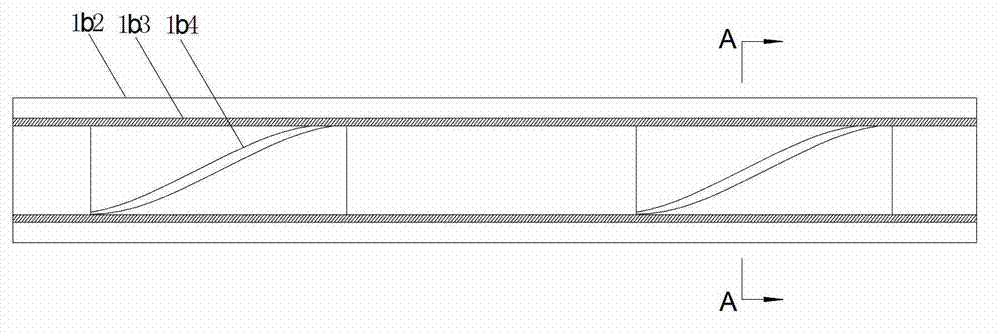

[0036] figure 2 It is a structural schematic diagram of the first embodiment of the solar automatic heat-spreading heat-gathering tube of the present invention. Among them, 1b2 is the glass tube of the outer layer of the solar automatic heat soaking tube, 1b3 is the absorption tube coated with a heat absorbing layer on the inner layer of the solar automatic heat soaking tube (1b3 is usually made of stainless steel, beryllium alloy (such as beryllium bronze) and other high temperature resistant Metal material, the space between 1b2 and 1b3 is a vacuum), 1b4 is the isolation plate set in the inner cavity of the absorption tube 1b3, 1b4 is made of the same material as 1b3 or a material with similar thermal performance. A-A indicates the position and view direction of the cross-section of the forced-heating trough module (that is, cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com